A pressing device

A technology of pressing equipment and sliding table mechanism, which is applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of low assembly efficiency and operator fatigue, so as to improve the pressing efficiency, save labor costs, The effect of increased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

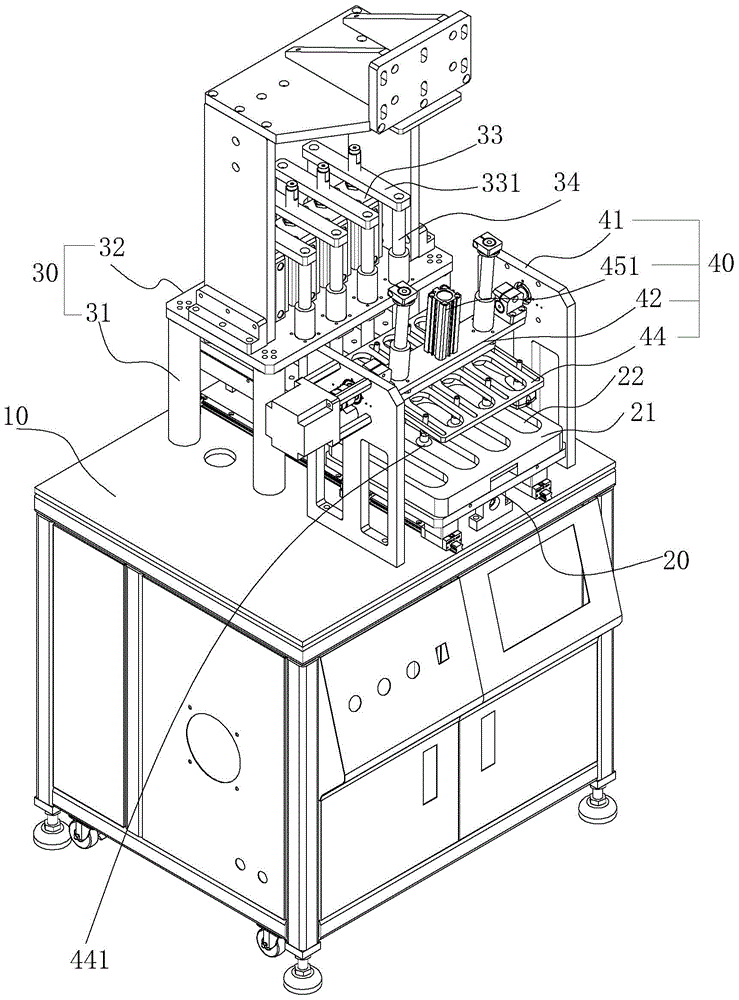

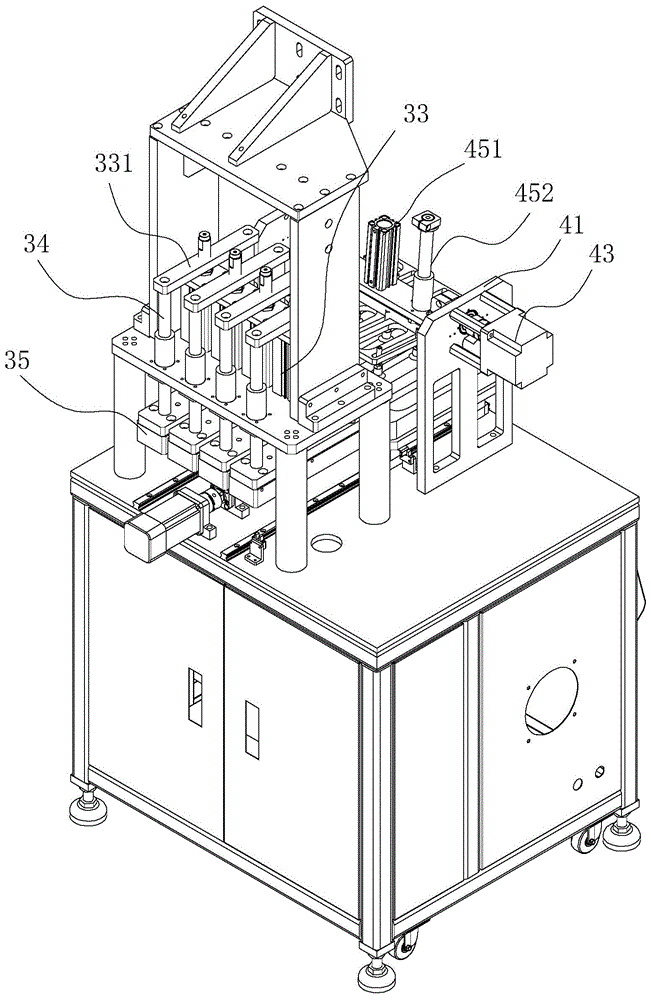

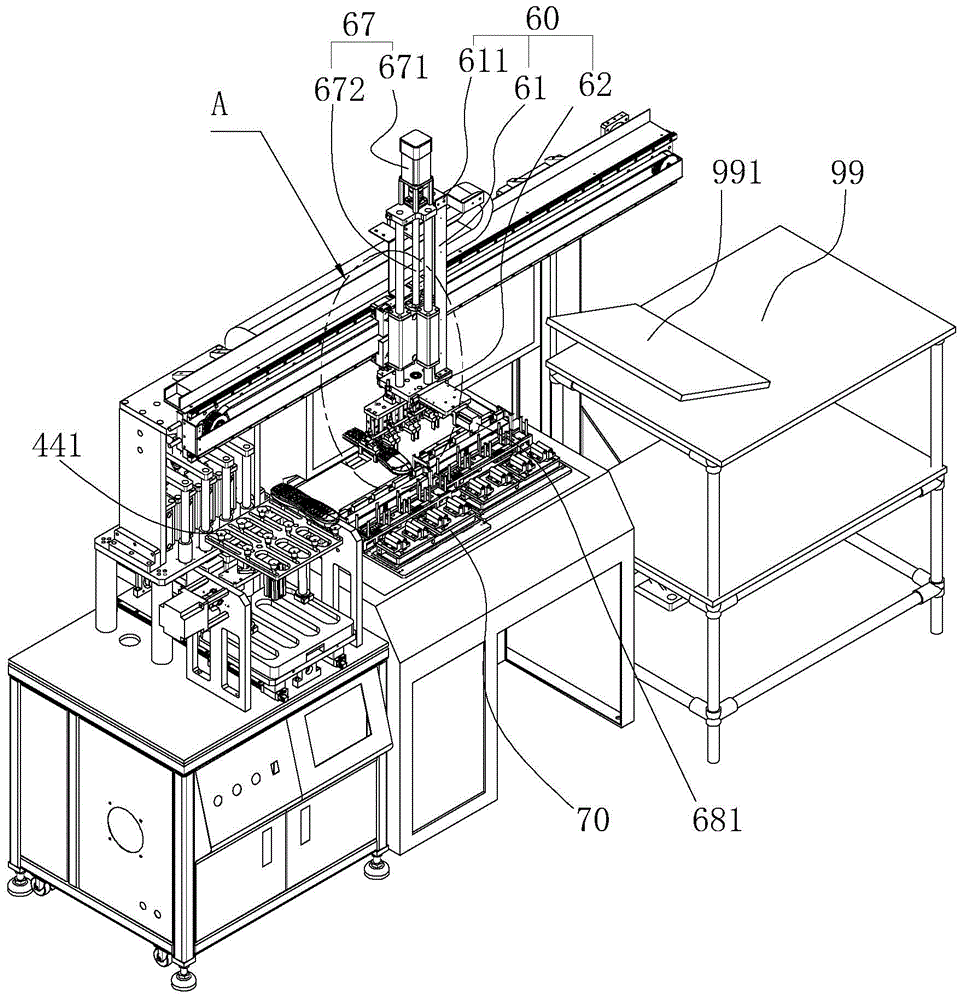

[0027] Such as Figure 1-5 The specific embodiment shown is a pressing device of the present invention, which includes a machine base 10, on which a longitudinal slide mechanism 20 and a frame-shaped support 30 are arranged, and the frame-shaped support 30 includes The vertical column 31, and the upper fixed plate 32 connected with the upper ends of the column 31 on both sides, the longitudinal slide mechanism 20 is provided with a jig 21, and the jig 21 is provided with a workpiece lower cavity 22; the upper fixed plate 32 is fixed with a press The combined power part (that is, the cylinder 33) and the press-fit guide mechanism that guides the press-fit power part (in this embodiment, the press-fit guide mechanism is two (located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com