Defogging device for double-hook waved plate

A technology of demisting device and corrugated plate, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of low separation efficiency of the separator, difficult to separate mist, and large equipment investment, and achieve follow-up services. Fast and reliable, providing convenient and timely effects with less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

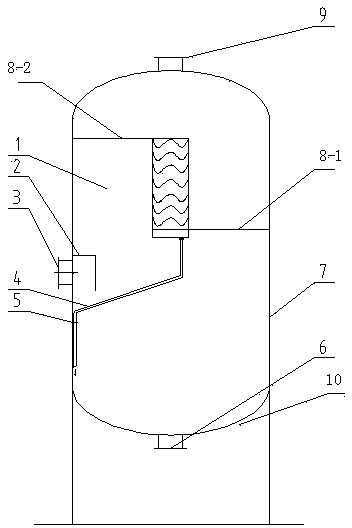

[0027] Such as Figures 1 to 7 As shown, a corrugated plate defogger is characterized in that it includes a corrugated plate defogger 1, a gas inlet 3, a liquid discharge port 6, a housing 7 and a gas outlet 9; one side of the housing 7 is provided with The gas inlet 3, the liquid discharge port 6 are set at the lower part of the shell 7, the gas outlet 9 is set at the upper part of the shell 7, and the corrugated plate demister 1 is set inside the shell 7, and the corrugated plate demister 1 is set at the gas inlet 3 and the gas Between exit 9.

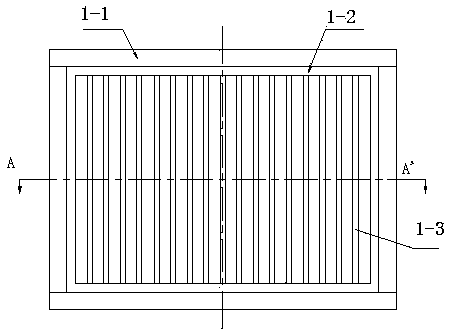

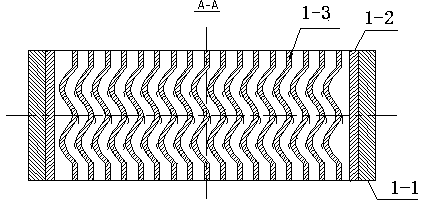

[0028] The corrugated plate demister 1 is composed of a first shell 101, a second shell 102 and a corrugated plate assembly 103; the second shell 102 is embedded in the first shell 101 to form a hollow separation space; the corrugated plate The component 102 is arranged in a separate space, and the corrugated plate component 102 is composed of no less than two corrugated plates.

[0029] The housing 7 is also provided with a concav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com