One-way breathable valve and breathable shoes with the one-way breathable valve

A technology of ventilating valve and ventilating shoes is applied in the field of ventilating shoes, which can solve the problems of narrow space between the heel and the ground, water leakage, insufficient ventilation, etc., and achieve the effects of improving service life, unique concept and good ventilation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

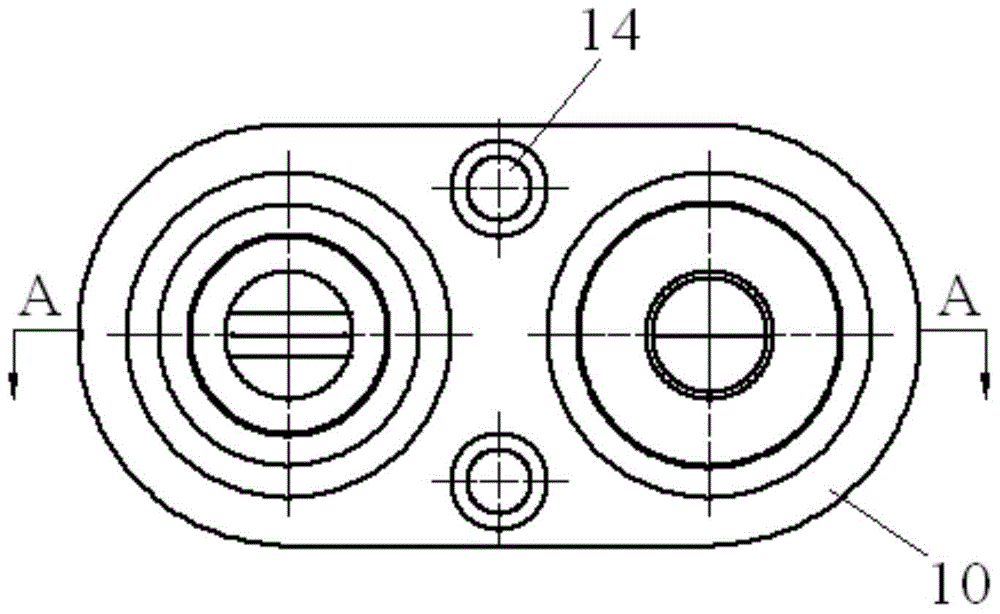

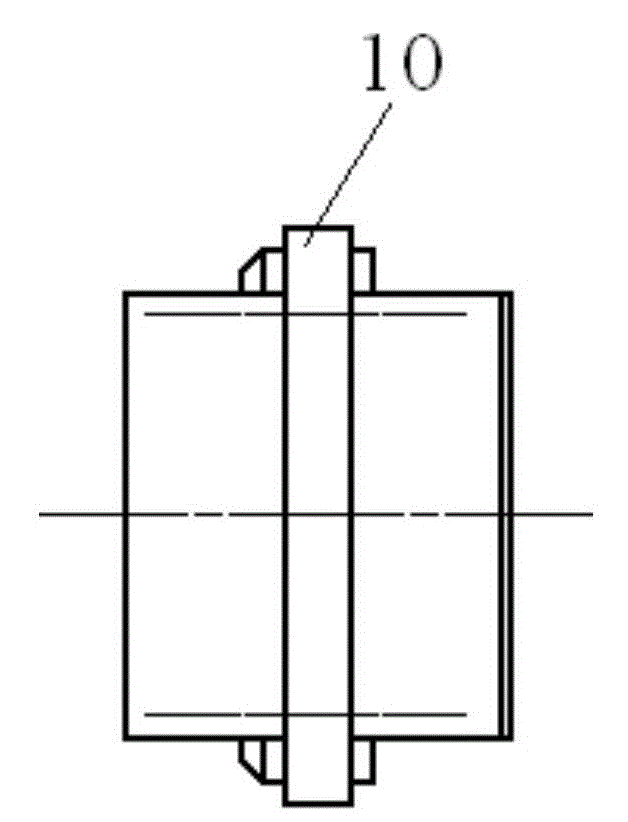

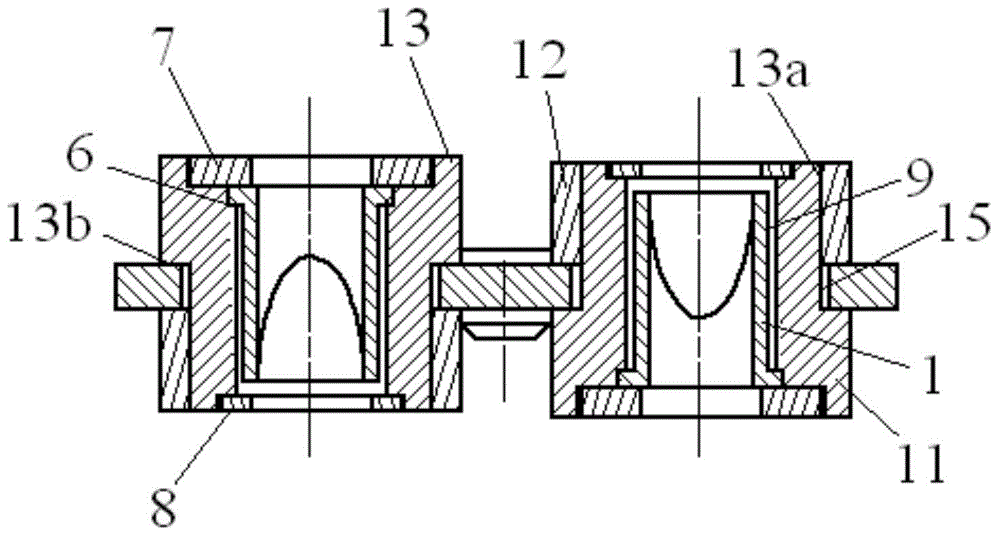

[0036] Such as Figure 1~5 Shown: a one-way breathable valve, including a valve body, the valve body is provided with two independent air inlet passages 16 and outlet passages 17, the inlet passage 16 and the outlet passage 17 are provided with two opposite directions and the same structure An elastic spool 1; the spool 1 is a hollow structure with an air inlet 2 at one end; the outer wall of the other end of the spool 1 is provided with two opposite wedge-shaped surfaces 3, and the intersection of the two wedge-shaped surfaces 3 is provided with a preset The air outlet slit 4; the side wall of the spool 1 is sealed and fixed with the inner wall of the air inlet passage 16 or the air outlet passage 17.

[0037] Such as Figure 4 As shown: the valve core 1 can be made of various elastic or flexible materials. In this embodiment, the valve core 1 is made of rubber. The outer wall of the valve core 1 is provided with an annular fixed arm 5; the fixed arm 5 is sealed and fixed to ...

Embodiment 2

[0042] Such as Figure 6-8 As shown, a kind of air-permeable shoe comprises sole 19 and upper of a shoe 20, and the upper of a shoe that two shoes are arranged opposite is provided with one-way ventilation valve 21, and each shoe is provided with one. The structure of the one-way breathable valve 21 is the same as in Embodiment 1. During actual installation, corresponding installation holes are provided on the shoe upper 20, and the one-way breathable valve can be fixed through the riveting holes or riveting grooves 14.

[0043] When a person walks, the air pressure in the shoe will be affected. When the air pressure in the shoe is lower than the external air pressure, the gas enters the valve core 1 from the air inlet 2 of the valve core 1 in the air intake passage 16, and the momentum of the gas enters into the valve core 1. Under the action, the elastic air outlet slit 4 is opened to realize the entry of gas. When the air pressure in the shoe is greater than the external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com