Mining hole-digging wall-protection electric equipment capable of rotating for n*360 degrees

A technology of electric equipment and electric motor, which is applied in excavation, earthmoving machine/shovel, construction, etc., can solve the problems of difficulty in controlling the quicksand in the excavation section, slow construction speed, and incapable of continuous construction, and achieves simple and reasonable structure and construction. Fast, strong walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

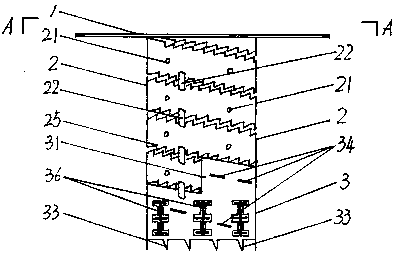

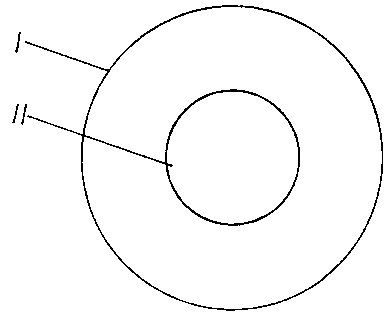

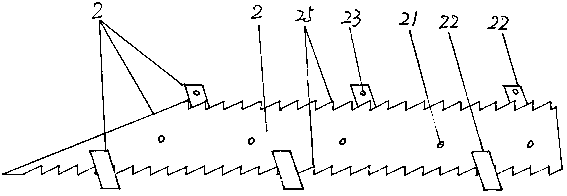

[0012] The invention is attached figure 1 , 2 , 3, and 4, the equipment is composed of a circular mouth guard 1, a sawtooth strip guard 2 and a rotating casing 3 with climbing gear rollers, one end of the sawtooth strip guard 2 is connected with the circular mouth guard 1, The other end is connected to the rotating casing 3 with climbing gear rollers. The circular mouth guard 1 has a round opening 11 in the center. The sawtooth strip guard 2 forms a wall cylinder, and the support for the hole wall is firm, safe and reliable. Fixing holes 21 and fixed blocks 22 are set on the strip guard 2, and the fixed blocks 22 are separated on both sides of the sawtooth strip guard 2, and holes 23 on the stop 22 on one side can be connected with bolts 24 and sawtooth strip guards. The plates 2 are connected, the serrations 25 on both sides of the saw-toothed guard plate 2 are meshed and buckled to form a cylinder, the anchor rod is inserted to the periphery of the hole wall through the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com