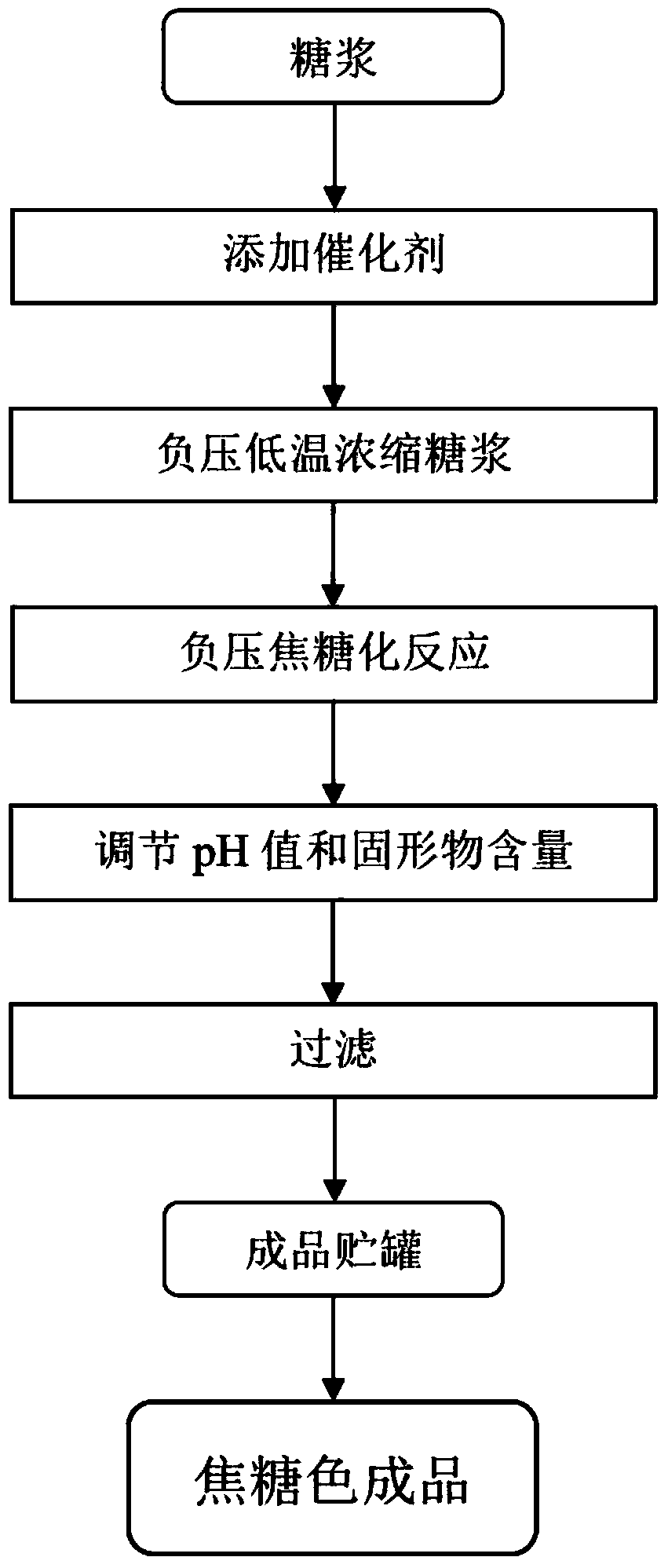

Production process of caramel color

A production process and caramel color technology, applied in the field of caramel color production process, can solve the problems of large heat energy demand, resinization, affecting product quality, etc., and achieve the effects of less equipment investment, good salt tolerance, and reduced adverse reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] at 10m 3 Taking the reactor as an example, the production process of caramel color includes the following steps:

[0041] (1) Add 8 tons of starch syrup with a solid content of 77% into the reactor, and add catalyst phosphoric acid according to 0.1% of the solid content of the syrup;

[0042] (2) Set the pressure in the reactor to -0.8MPa, keep the temperature at 65°C, concentrate the solid content of the syrup to 91%, and then raise it to 140°C; then control the pressure in the reactor to -0.3MPa, and react for 12 hours;

[0043] (3) Adjust the pressure inside the kettle to normal pressure, add process water to the reaction kettle to cool down to stop the caramelization reaction, add NaOH (30%) solution, adjust the pH to about 4.8, and adjust the solid content to 80% at the same time; filter to remove impurities , cooled to about 60°C and pumped into the finished product storage tank, and the package is a caramel-colored finished product.

[0044] The indicators of ...

Embodiment 2

[0046] With reference to the production technology of the caramel color of embodiment 1, comprise the following steps:

[0047] (1) Add 8 tons of starch syrup with a solid content of 71% into the reactor, and add catalyst citric acid according to 0.3% of the solid content of the syrup;

[0048] (2) Set the pressure in the reactor to -0.7MPa, keep the temperature at 68°C, concentrate the solid content of the syrup to 93%, and then rise to 145°C; then control the pressure in the reactor to -0.05MPa, and react for 8 hours;

[0049] (3) Adjust the pressure in the kettle to normal pressure, add process water to the reaction kettle to cool down to terminate the caramelization reaction, add NaOH (30%) solution, adjust the pH to about 4.8, and adjust the solid content to 75% at the same time; filter to remove impurities , cooled to about 60°C and pumped into the finished product storage tank, and the package is a caramel-colored finished product.

[0050] The indicators of the produ...

Embodiment 3

[0052] With reference to the production technology of the caramel color of embodiment 1, comprise the following steps:

[0053] (1) Add 8 tons of starch syrup with a solid content of 75% into the reactor, and add catalyst sodium hydroxide according to 0.5% of the solid content of the syrup;

[0054](2) Set the pressure in the reactor to -0.5MPa, keep the temperature at 75°C, concentrate the solid content of the syrup to 92%, and then raise it to 160°C; then control the pressure in the reactor to -0.2MPa, and react for 4 hours;

[0055] (3) Adjust the pressure in the kettle to normal pressure, add process water to the reaction kettle to cool down to stop the caramelization reaction, add NaOH (30%) solution, adjust the pH to about 4.8, and adjust the solid content to 70% at the same time; filter to remove impurities , cooled to about 60°C and pumped into the finished product storage tank, and the package is a caramel-colored finished product.

[0056] The indicators of the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color rate | aaaaa | aaaaa |

| Color rate | aaaaa | aaaaa |

| Color rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com