Ratchet wheel screw driver acting bidirectionally

A screwdriver and ratchet technology, applied in the field of ratchet screwdrivers, can solve the problems of high cost of gear components, short service life, affecting screwdrivers, etc., and achieve the effects of low cost, long service life and improved operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

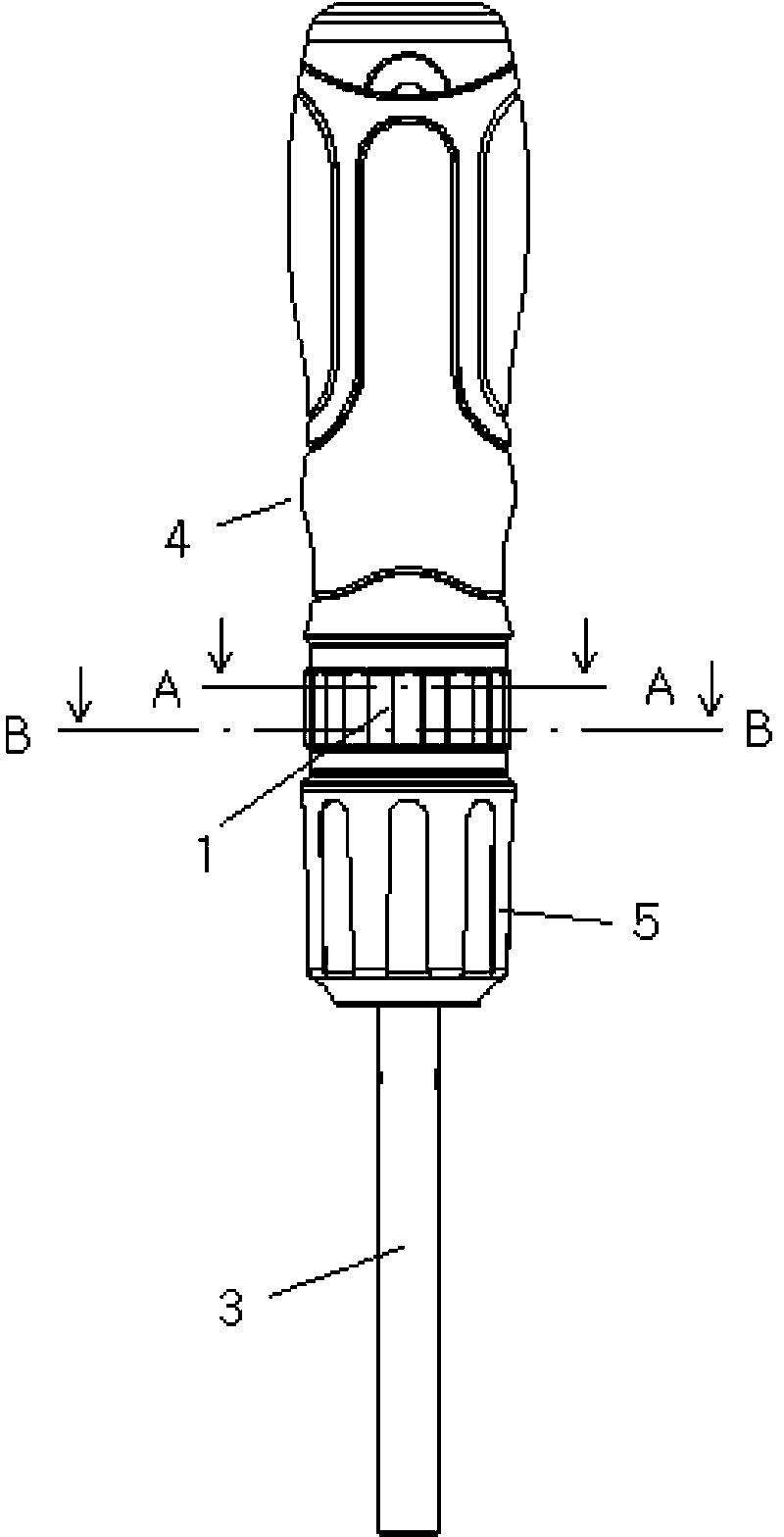

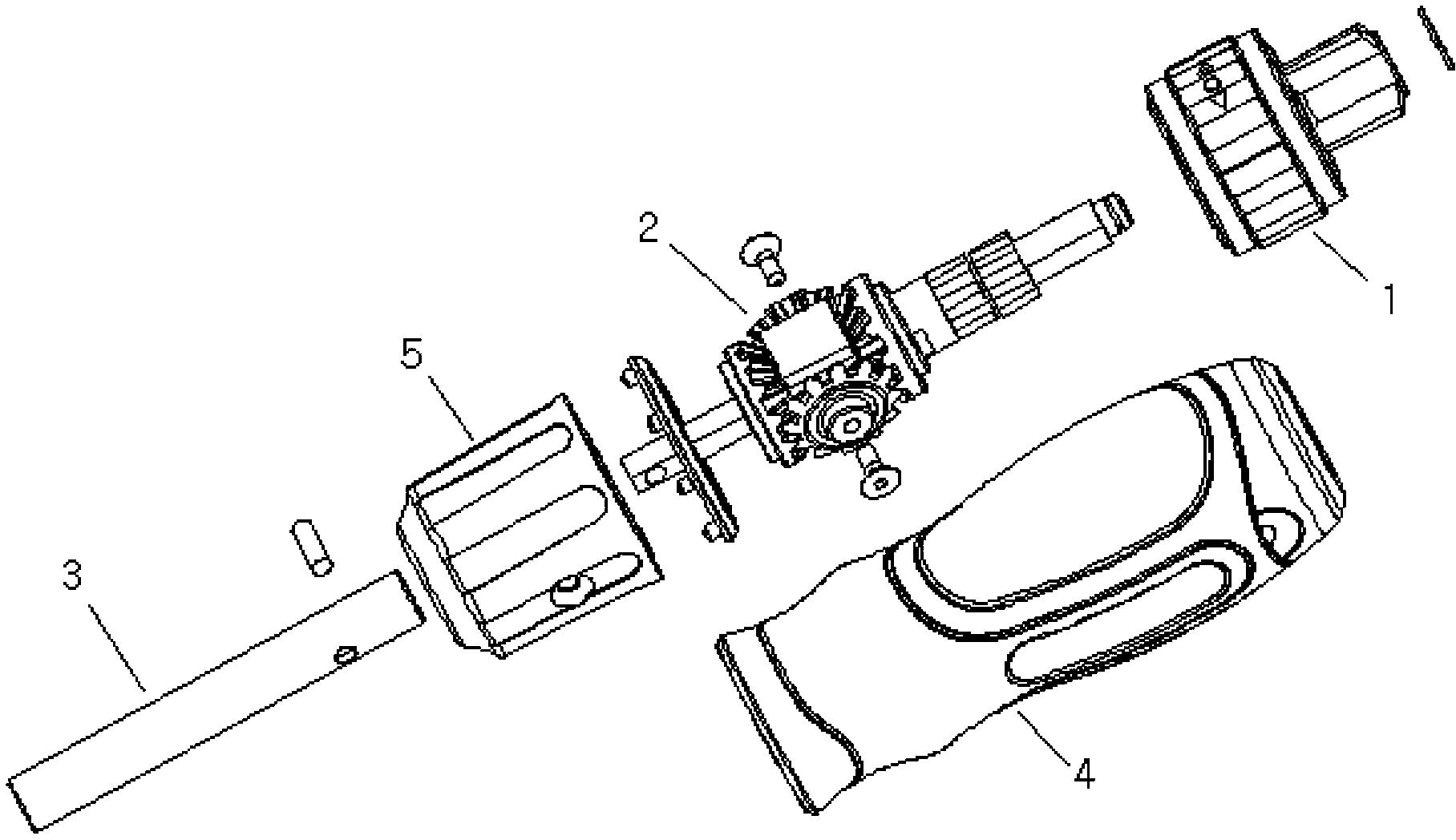

[0032] Such as Figure 1-Figure 12 As shown, a two-way working ratchet screwdriver provided by the embodiment of the present invention includes a knife bar 3, a handle 4, a two-way transmission device, and a reversing device 1;

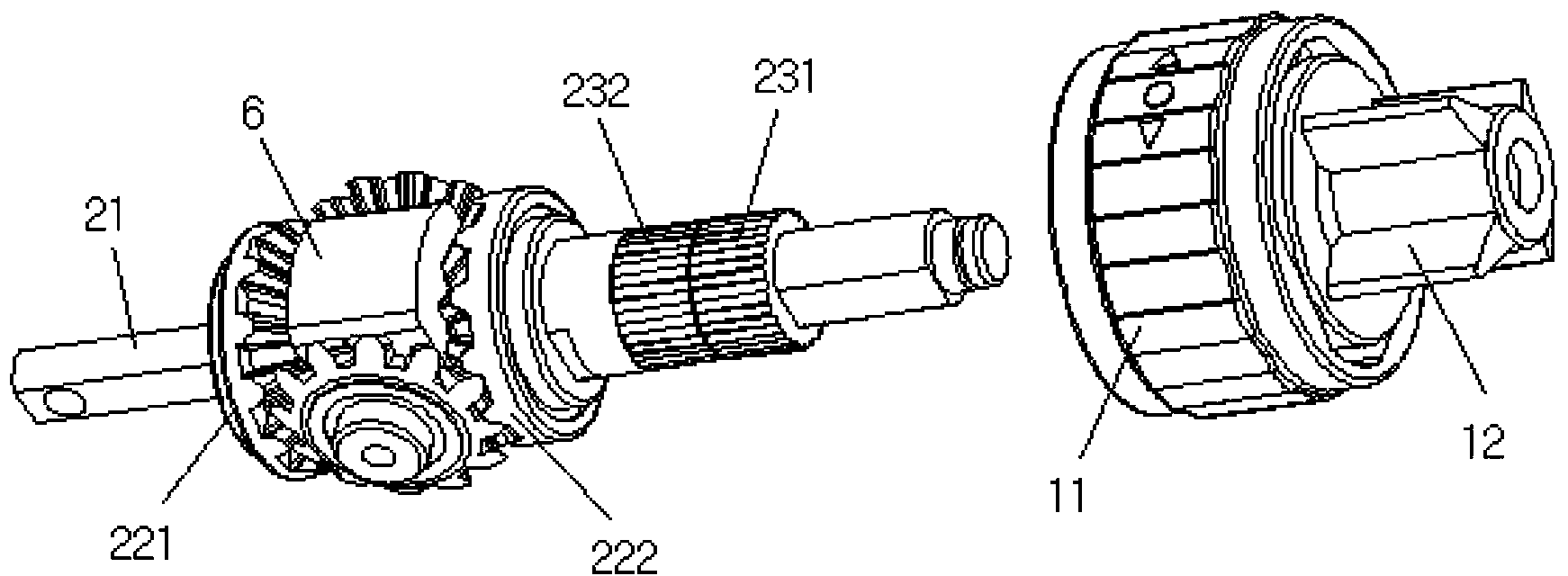

[0033] The two-way transmission (see image 3 , Figure 4 ) includes a central shaft 21, and two driving gears 221, 222, and two ratchet gears 231, 232; the two driving gears are respectively the first driving gear 221 and the second driving gear 222, and the two ratcheting gears are respectively It is the first ratchet gear 231 and the second ratchet gear 232. The two driving gears and the two ratc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com