Fresh red rice cheese and preparation method thereof

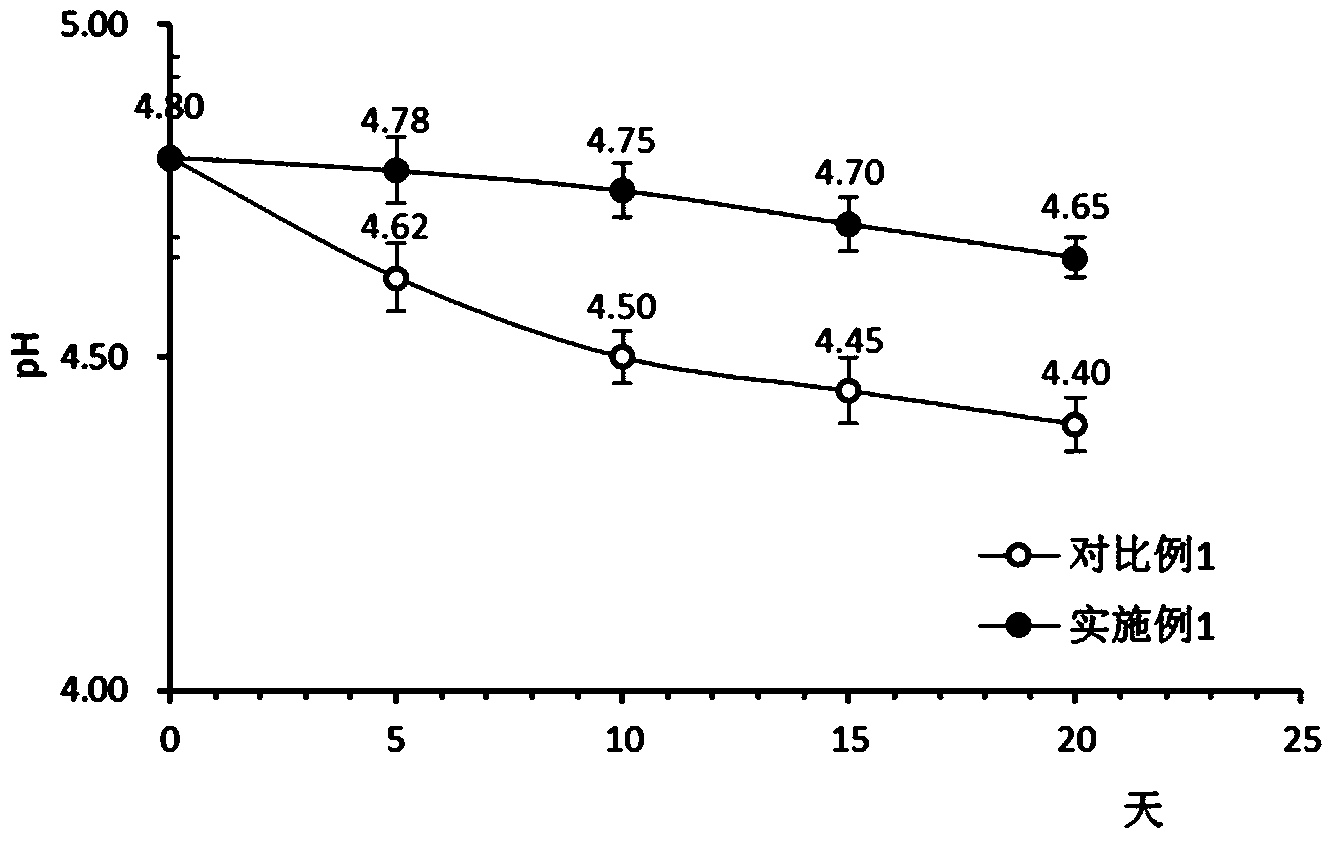

A technology of fresh cheese and red yeast rice, applied in the field of red yeast rice fresh cheese and its preparation, can solve the problems of flavor and texture deterioration, acidity rise, etc., achieve long shelf life and avoid flavor and texture deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

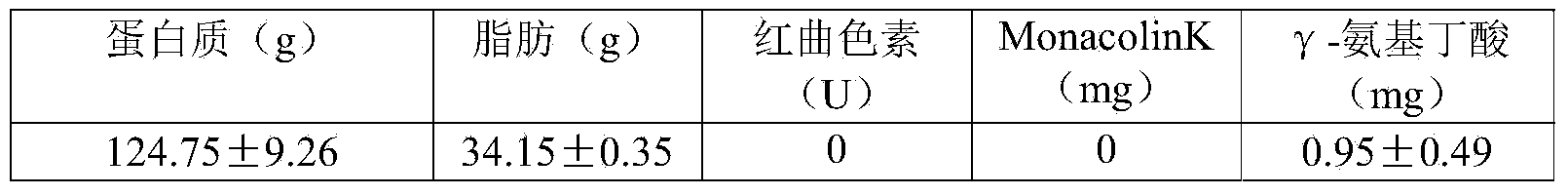

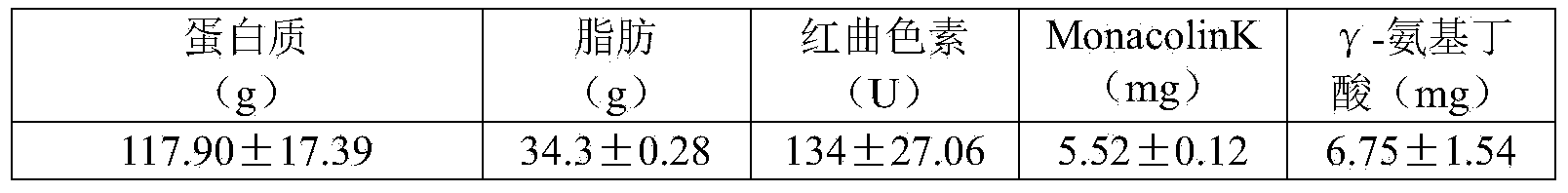

Embodiment 1

[0036] 100 kg of raw milk was sterilized at 72°C for 15 seconds and cooled to 30°C, 5% homogenized Monascus culture broth was added to the raw milk to ferment, and the pH of the raw milk was 4.8. Add 0.02%~0.05% rennet of the raw milk quality, stir evenly, and leave to ferment until the pH value is 4.6 to form curd. After cutting, the obtained curd mass is heated to 50°C within 120 minutes, and then washed with 50°C sterile water to remove whey. After washing twice with sterile water at 5°C, finally washing with sterile water at 1°C and keeping it for a period of time to make the cheese curd temperature lower than 4°C, drained and filled into the container to prepare fresh red yeast rice cheese.

Embodiment 2

[0038] 100 kg of raw milk was sterilized at 72°C for 15 seconds and cooled to 30°C, 5% of the homogenized Monascus culture broth was added to the raw milk to ferment, and fermented until the pH of the raw milk was 5.0. Add 0.02%~0.05% rennet of the raw milk quality, stir evenly, and leave to ferment until the pH value is 4.6 to form curd. After cutting, the obtained curd mass is heated to 50°C within 120 minutes, and then washed with 50°C sterile water to remove whey. After washing twice with sterile water at 5°C, finally washing with sterile water at 1°C and keeping it for a period of time to make the cheese curd temperature lower than 4°C, drained and filled into the container to prepare fresh red yeast rice cheese.

Embodiment 3

[0040] Sterilize 100 kg of raw milk at 72°C for 15 seconds and cool to 30°C, add 5% homogenized Monascus culture broth to the raw milk for fermentation, and ferment until the pH of the raw milk is 5.2. Add 0.02%~0.05% rennet of the raw milk quality, stir evenly, and leave to ferment until the pH value is 4.6 to form curd. After cutting, the obtained curd mass is heated to 50°C within 120 minutes, and then washed with 50°C sterile water to remove whey. After washing twice with sterile water at 5°C, finally washing with sterile water at 1°C and keeping it for a period of time to make the cheese curd temperature lower than 4°C, drained and filled into the container to prepare fresh red yeast rice cheese.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com