Transverse flow marine turbine with autonomous stages

A technology of turbine engine and turbine, which is applied in the direction of reaction engine, wind turbine and engine at right angles to the wind direction, and can solve problems such as inability to provide efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

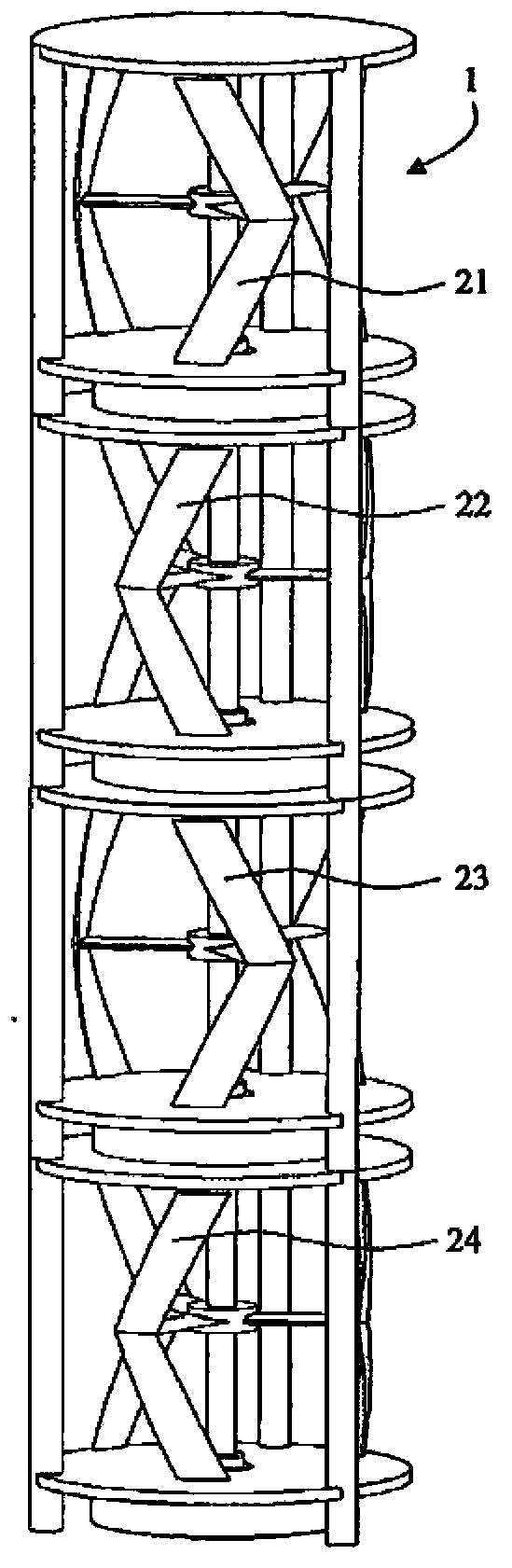

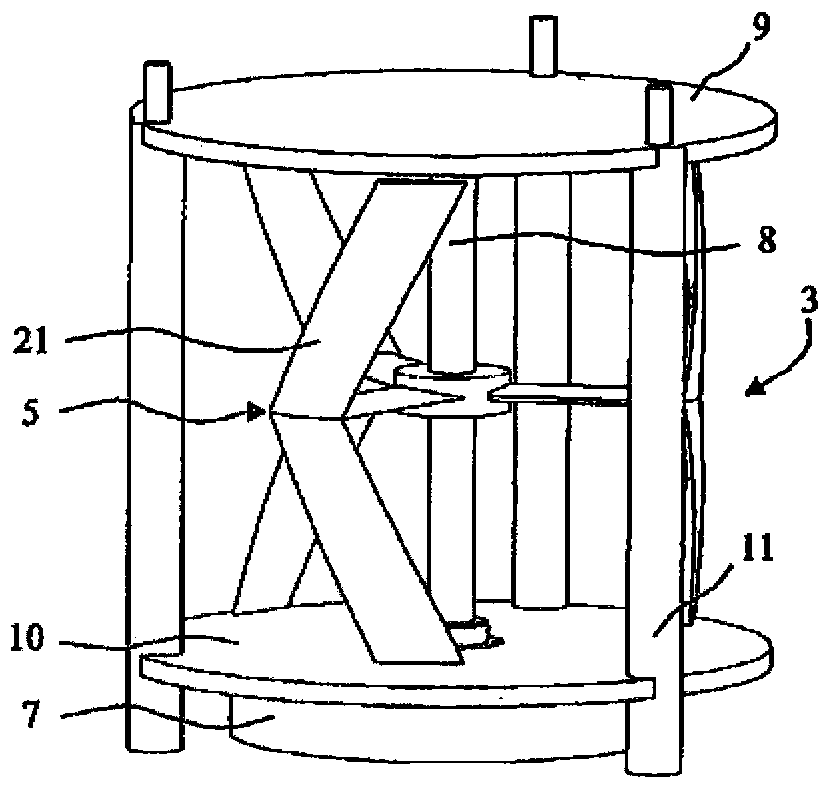

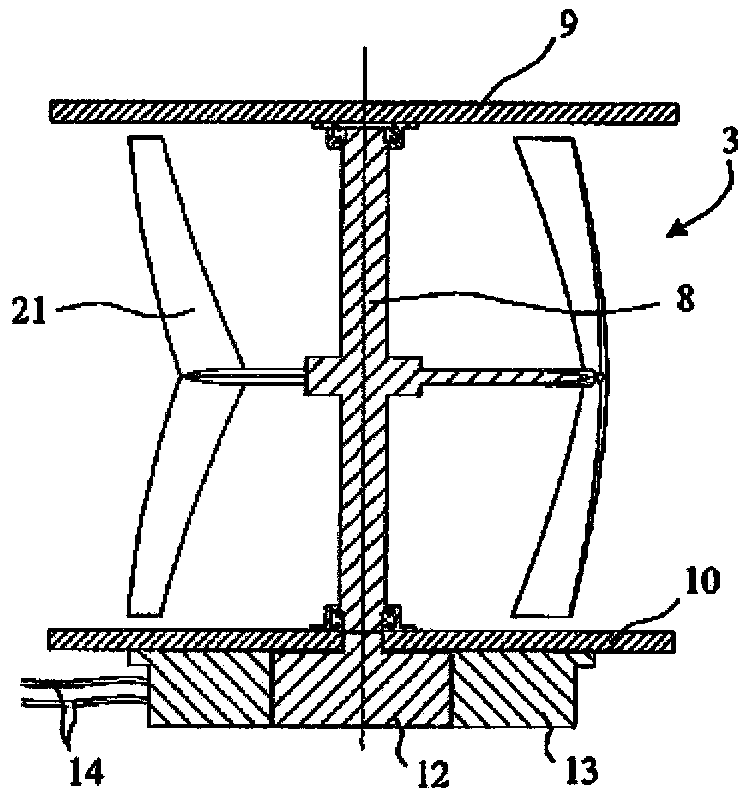

[0040] Figure 1A , Figure 1B and Figure 1C are simplified diagrams showing a single-row cross-flow water turbine engine, a perspective view of a stage of the turbine engine, and a partial cutaway view of a stage of the turbine engine, respectively. These views are simplified in particular in that they do not show components for attaching or connecting the turbine engine. The turbine engine 1 consists of a set of stages 3 , each stage comprising a cross-flow turbine 5 and a generator 7 . For example, each basic turbine is of the type described in patent application 04 / 50209 (B6412) and is firmly attached to a shaft 8 which is rotatably fitted between an upper flange 9 and a lower flange 10, the upper The flange 9 and the lower flange 10 are connected by a rod 11 . The shafts of the individual turbine-generator stages are independent of each other. Each shaft 8 drives a rotor 12 of a generator 7 , which rotates inside a stator 13 , which provides an electrical supply via ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com