Continuous feeding device and process of cement kiln cooperation urban garbage system

A technology for co-processing, municipal waste, applied in combustion methods, combustion types, incinerators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

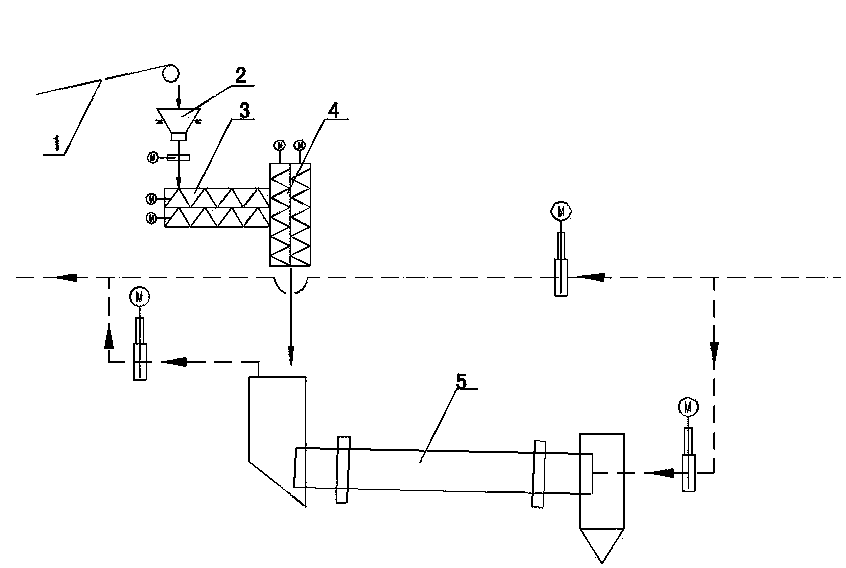

[0025] As shown in the figure: the continuous feeding device of the cement kiln cooperative processing urban waste system is used to transport materials to the L-shaped garbage incinerator 5. The feeding system includes a belt conveyor 1, and the upper part of the belt conveyor 1 The material end is set at the output section of the garbage pretreatment system, and the feeding system also includes a steady flow bin 2, a horizontal screw conveyor 3 and a vertical screw conveyor 4, and the steady flow bin 2 is set on the belt conveyor 1 for feeding Below the end, the discharge port of the steady flow bin 2 is connected to the feed port of the horizontal screw conveyor 3, the vertical screw conveyor 4 is set at the tail end of the horizontal screw conveyor 3, and the outlet of the horizontal screw conveyor 3 The feed port is communicated with the feed port of the vertical screw conveyor 4, and the discharge port of the vertical screw conveyor 4 is connected to the feed port of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com