Oil storage piston pin for reciprocating type compressor capable of realizing starting lubrication convenience

A compressor and piston pin technology, which is used in machines/engines, liquid variable capacity machinery, mechanical equipment, etc., can solve the problems of large motor starting torque, large frictional resistance, and serious wear of compressors, and reduce the starting torque. , the effect of protection from wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

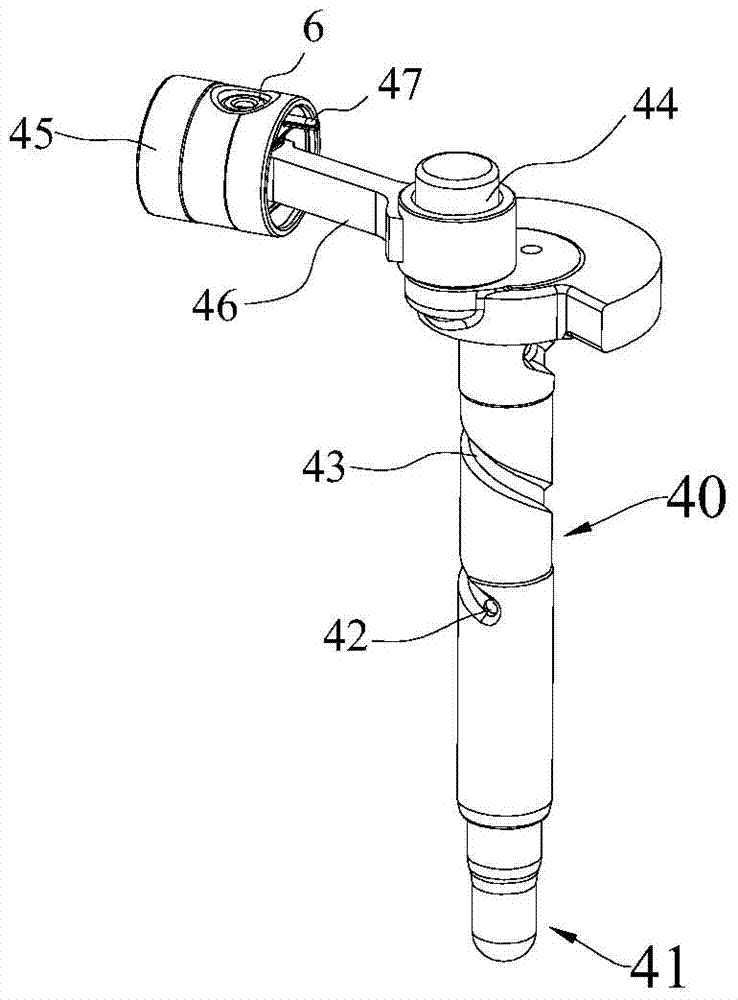

[0019] Reference Figure 3 ~ Figure 5 , Which shows the specific structure of the preferred embodiment of the present invention. The structural features of the present invention will be described in detail below, and if there are directions (up, down, left, right, front and back) described, it is Figure 4 The structure shown is for reference description.

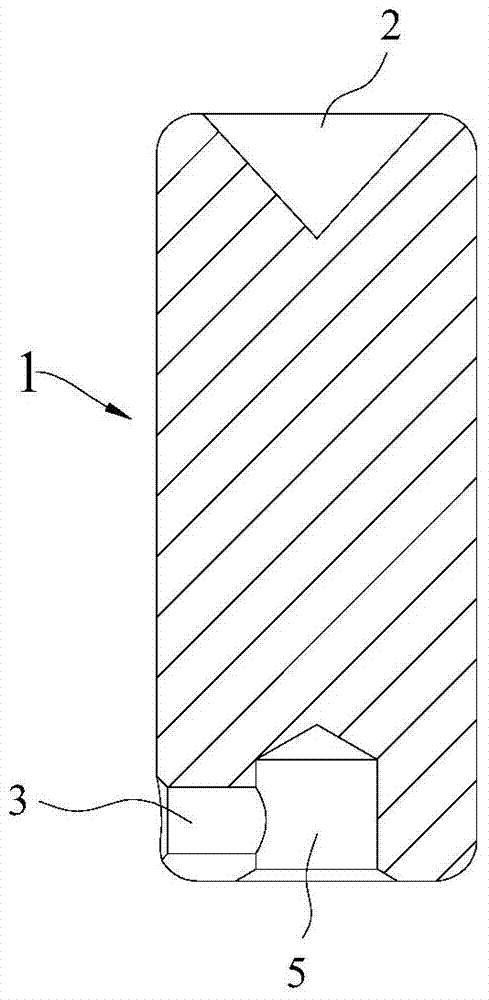

[0020] The present invention provides a reciprocating compressor oil-storing piston pin that is convenient for starting and lubricating. The piston pin includes a pin body 1, an oil storage structure 2 is provided at the upper end of the pin body 1, and a positioning pin installation side hole 3 is provided at the lower end of the pin body 1.

[0021] In the oil storage piston pin of the reciprocating compressor that is convenient to start and lubricate, an oil storage structure 2 is provided on the upper end surface of the pin body 1 to collect the lubricating oil remaining on the moving parts. When the compressor is started n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com