Textile machine with mounting and fixing means for second cable carrier guide

A support device, technology of textile machines, applied in the direction of continuous winding spinning machines, spinning machines, textiles and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

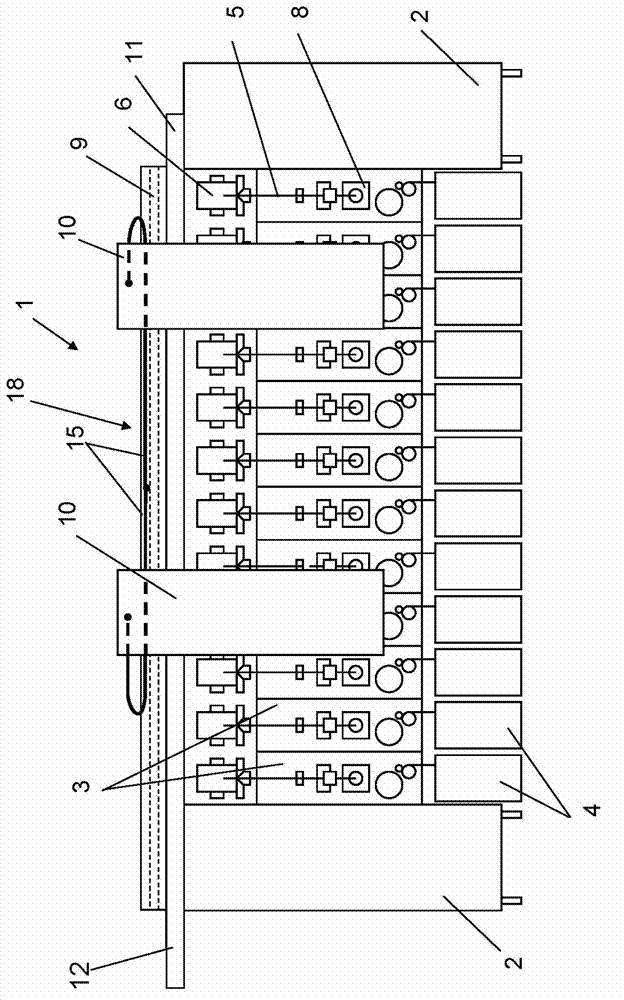

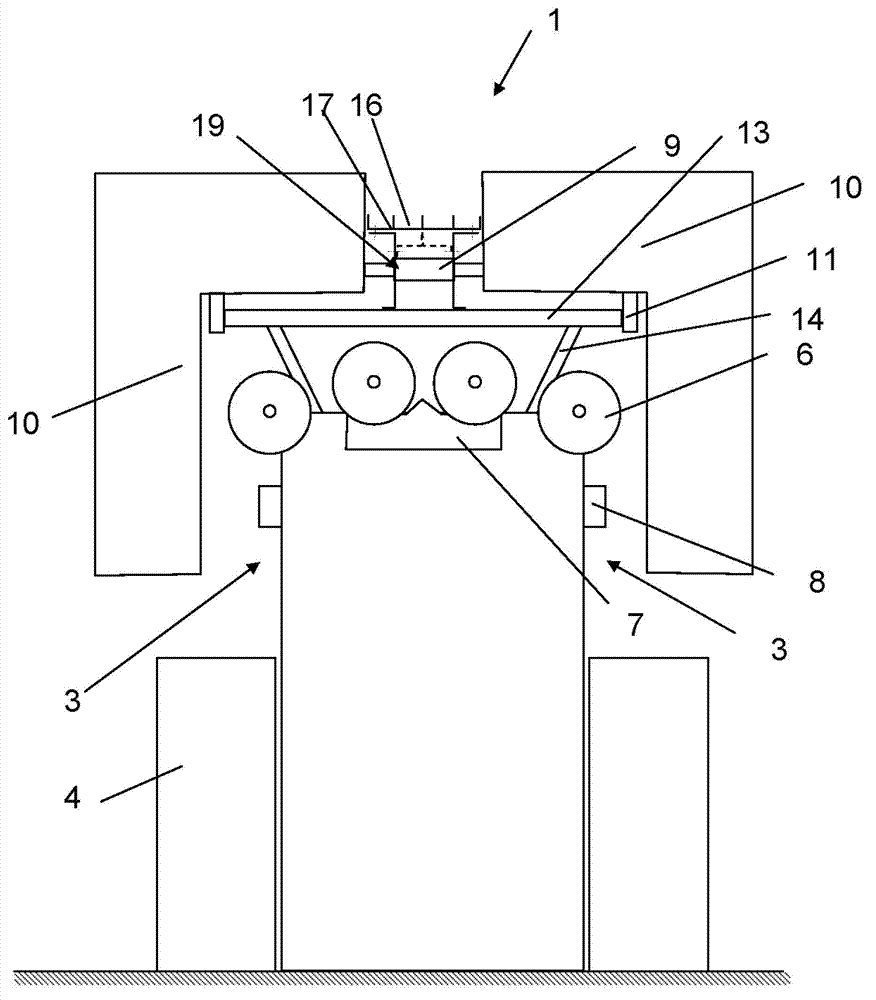

[0028] figure 1 A textile machine 1 is shown which is an open-end spinning machine. The invention can also be used on other spinning machines, such as air-jet spinning machines, or on other textile machines equipped with mobile service devices. In a well-known manner, the textile machine 1 consists of two machine frames 2 mounted on the upper end of the machine, in which are installed the different components for driving and controlling the textile machine and more important activities. A large number of work stations 3 are installed in the longitudinal direction of the textile machine 1 between the two machine frames 2 . In this open-end spinning machine, the job at the station is to spin the fiber material stored in the storage tank 4 into a thread 5 and then wind it into a coil 6 . In addition, the textile machine 1 also uses a device 7 for transporting coils that have been wound, such as figure 2 shown.

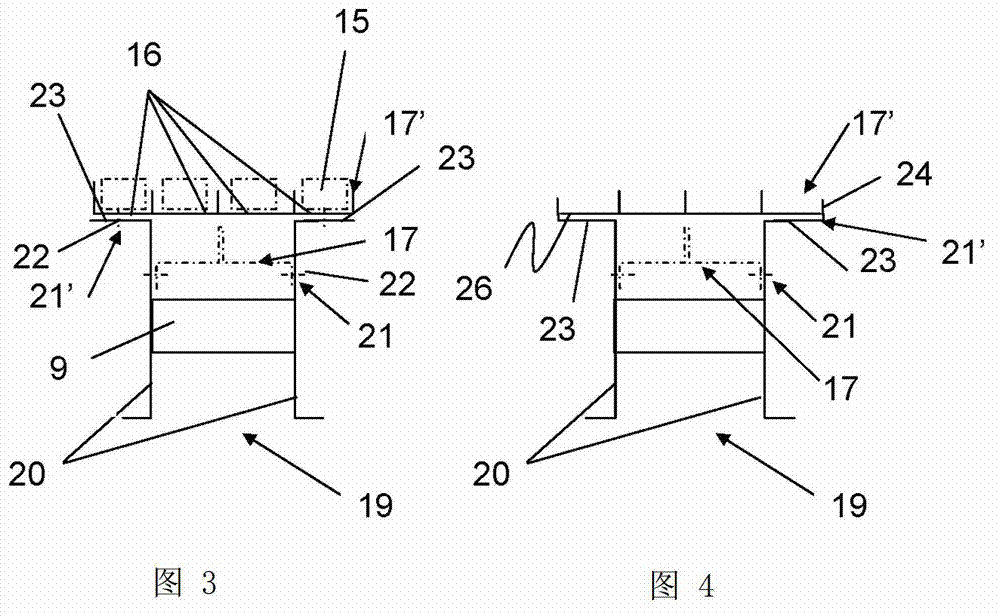

[0029]In order to provide materials or services to the workstat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com