Sludge dryer

A sludge drying and drying technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of poor operation stability, high energy consumption, unsatisfactory drying treatment effect, etc., and achieve stable and safe operation. , low energy consumption, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

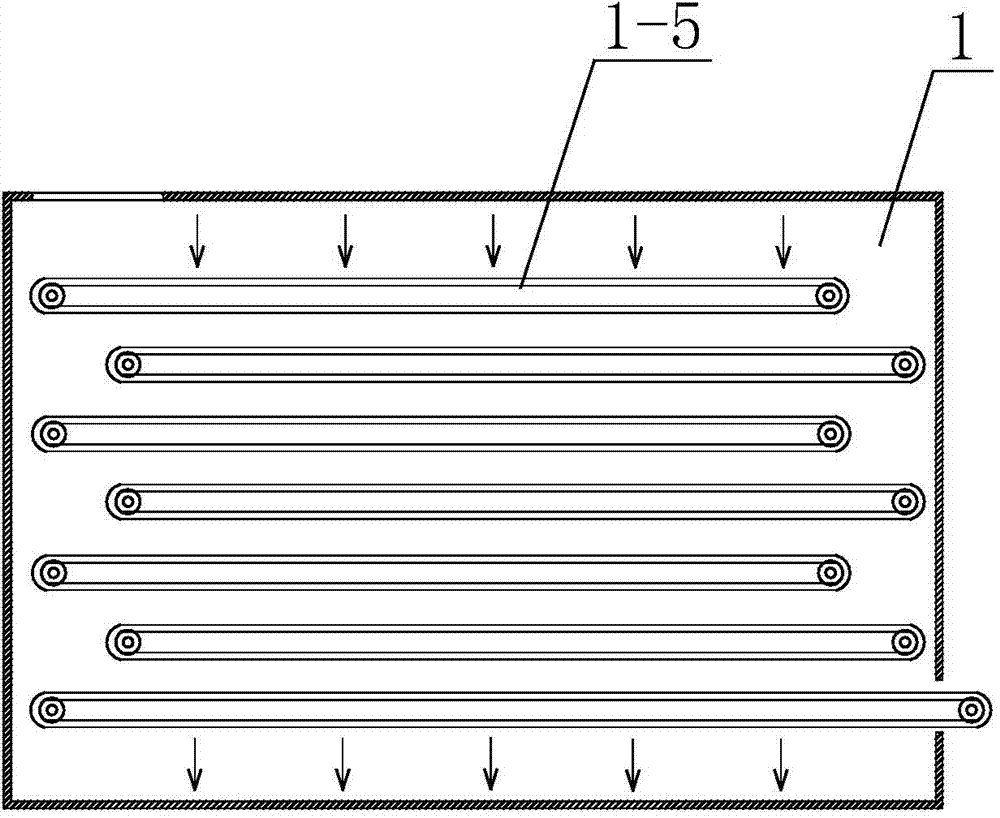

[0018] A sludge dryer, such as figure 1 , figure 2 As shown, it includes a drying chamber 1 and a circulating air heating chamber 2. The top of the drying chamber 1 is provided with a hot air inlet 1-1, and near the bottom is provided with a circulating air outlet 1-2 and a supplementary air inlet 1-3. There are supplementary air outlets 1-4 at the bottom. In the drying chamber 1, there are several layers of stainless steel mesh belt conveyors 1-5 driven by frequency conversion motors in parallel and staggered from top to bottom. The conveying end of the conveyor table 1-5 protrudes from the drying chamber 1, the top of the circulating air heating chamber 2 is provided with a hot air outlet 2-1, and the bottom is provided with a mixed air inlet 2-2, and the circulating air heating chamber 2 is provided with a The heat exchanger 2-3, the hot air outlet 2-1 of the circulating air heating chamber 2 communicates with the hot air inlet 1-1 of the drying chamber 1 through the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com