Butt joint structure of hopper plate and plate seam and hopper applying the butt joint structure

A hopper plate and hopper technology, which is applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of increasing the stress concentration of the hopper, the hopper cannot produce a clamping effect, and the weld seam is easy to crack, so as to enhance the overall strength and rigidity , optimize mechanical properties, increase the effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

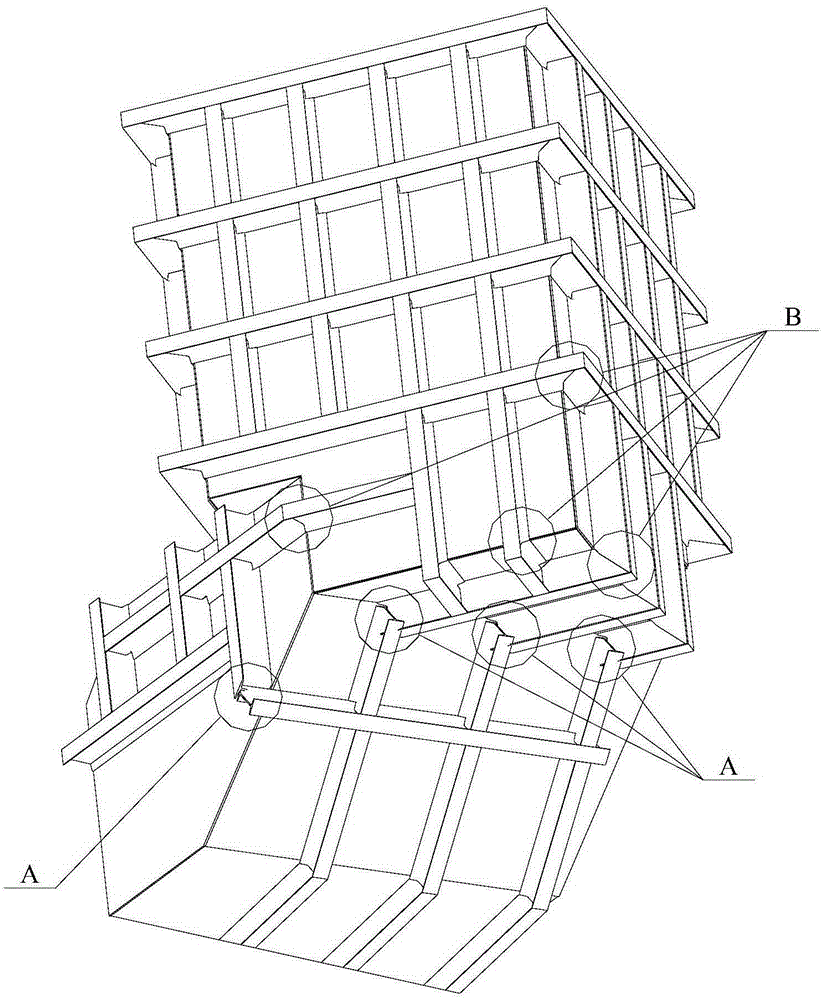

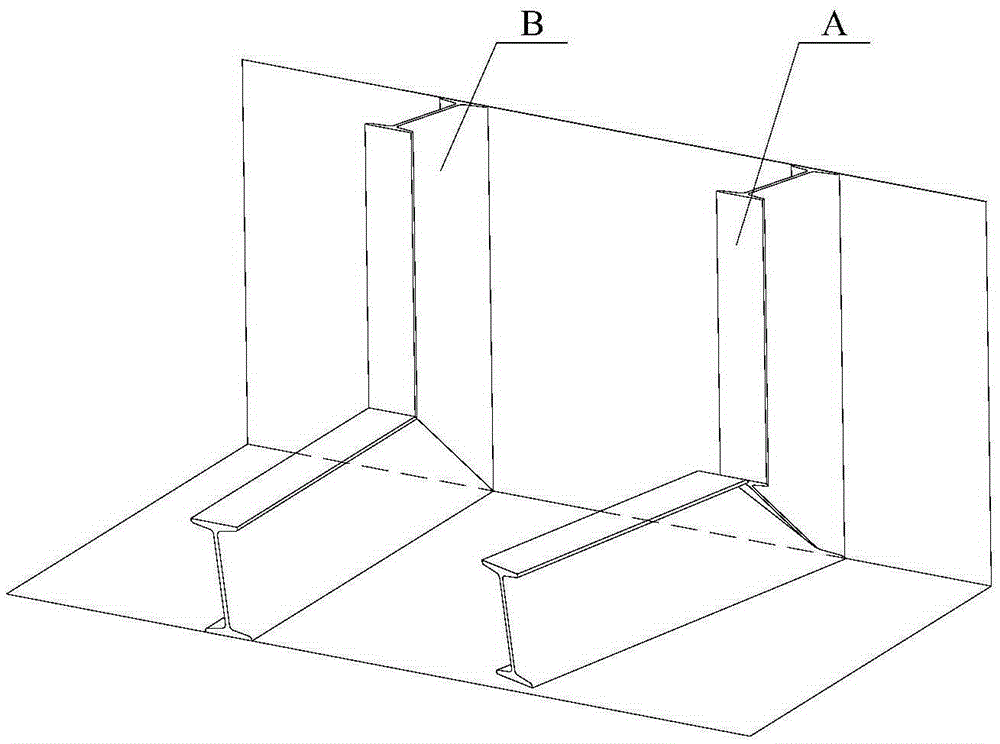

[0032] The core of the present invention is to provide a butt joint structure of hopper plates and plates to comprehensively optimize the mechanical properties of the butt joint structure, and to provide a reliable guarantee for reducing the weight and cost of the hopper on the basis of enhancing the overall strength and rigidity of the hopper. Without loss of generality, this embodiment will be described in detail below in conjunction with the accompanying drawings.

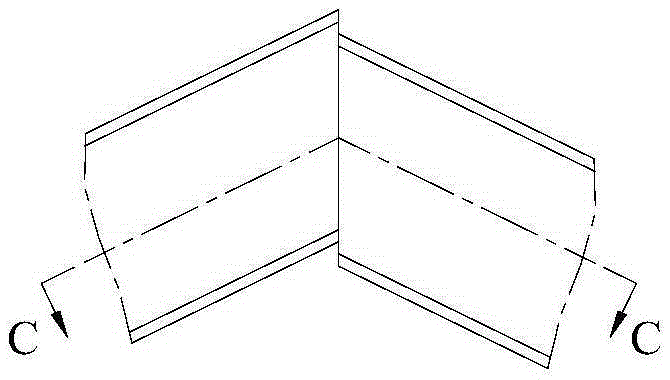

[0033] See Figure 5 The schematic diagram of the overall structure of the hopper is shown. The geometric shapes of the plates that make up the hopper are different. The adjacent hopper plates are respectively butted to form a bucket body with an internal cavity. The core invention point of this paper is not repeated here. Each hopper plate butt joint can apply the hopper plate seam butt joint structure provided by this embodiment. For detailed description of the structural principle, please refer to Image 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com