Automatic filled injection pump system

An automatic filling and syringe pump technology, applied in the direction of pressure infusion, devices introduced into the body, etc., can solve the problems of inaccurate control of contrast agent dilution concentration, high pipeline cost, residual waste, etc., to reduce the probability of adverse reactions and avoid The effect of secondary pollution and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

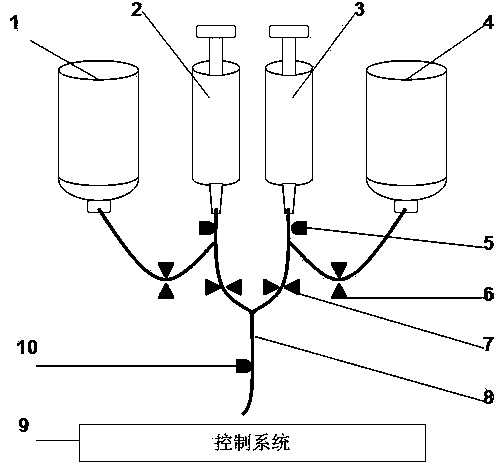

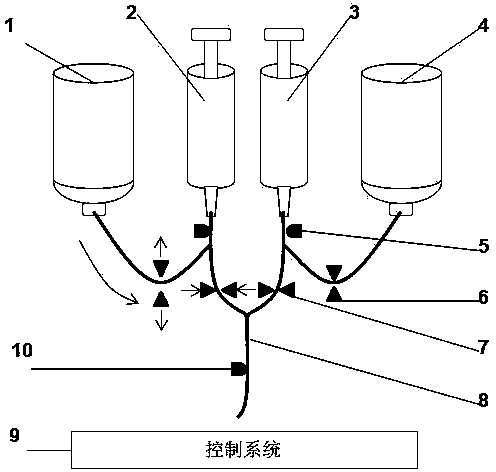

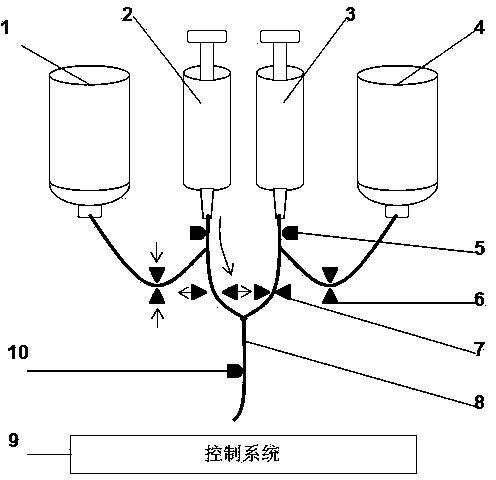

[0022] exist figure 1 In the structural diagram of the implementation example shown, the contrast agent branch and the saline branch are connected through the first Y-shaped interface, and the trunk merged into a Y-shaped trunk in the infusion direction is connected to the patient. The contrast agent injector (2) and the contrast agent container (1) are in fluid communication through the infusion tube (8), where the infusion tube (8) forms a second inverted Y-shaped joint, and the contrast agent injector (2) is connected at the second On the trunk of the first Y-shape, the contrast agent container (1) is connected to a branch of the second Y-shape, and the other branch is partly communicated with the saline pipeline in the direction of infusion. The filling stop valve (6) is located on the branch of the second Y-shaped contrast medium container (1), the filling air sensor (5) is located on the trunk of the second Y line, and the infusion stop valve (7) is located on the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com