Ceiling fan motor

A ceiling fan, motor shaft technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of loose overall space inside the motor, complex motor structure, increased use cost, etc., to achieve full utilization of the overall space and shorten the production process time. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

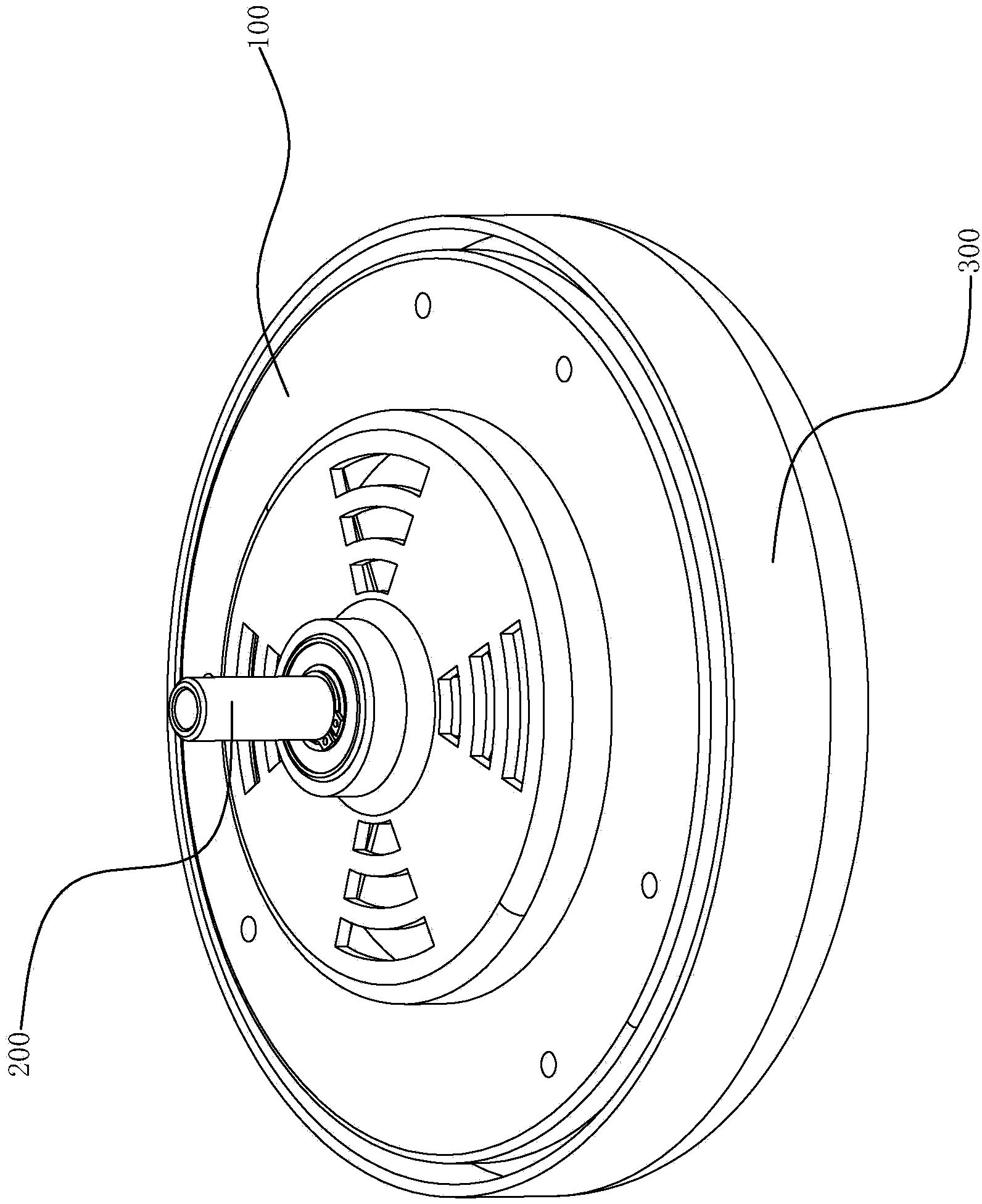

[0027] Such as figure 1 and figure 2 As shown, a ceiling fan motor of the present invention includes an end cover 100, a motor shaft 200, and a bottom cover 300. The end cover 100 is generally circular, and the end cover 100 is mainly composed of a circular top cover 110, an annular connecting portion 120, an The peripheral portion 130 is composed of the three integrally formed. The circular top cover 110 is arranged horizontally. The annular connecting portion 120 is located at the peripheral edge of the circular top cover 110 and extends vertically downward from the peripheral edge of the circular top cover 110. The annular peripheral portion 130 is also It is arranged horizontally, and the upper surface of the inner circle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com