A kind of fabrication process of diode

A preparation process and diode technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as insufficient automation, hidden dangers in products, and long-term production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

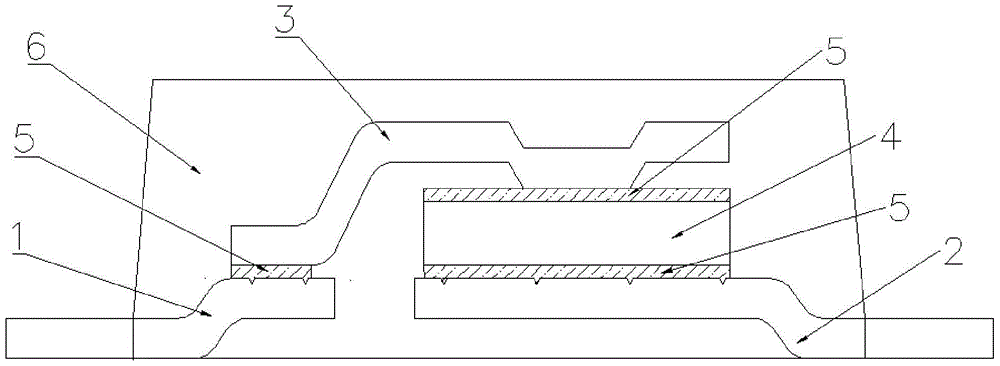

[0036] A kind of preparation technology of diode, comprises the following steps,

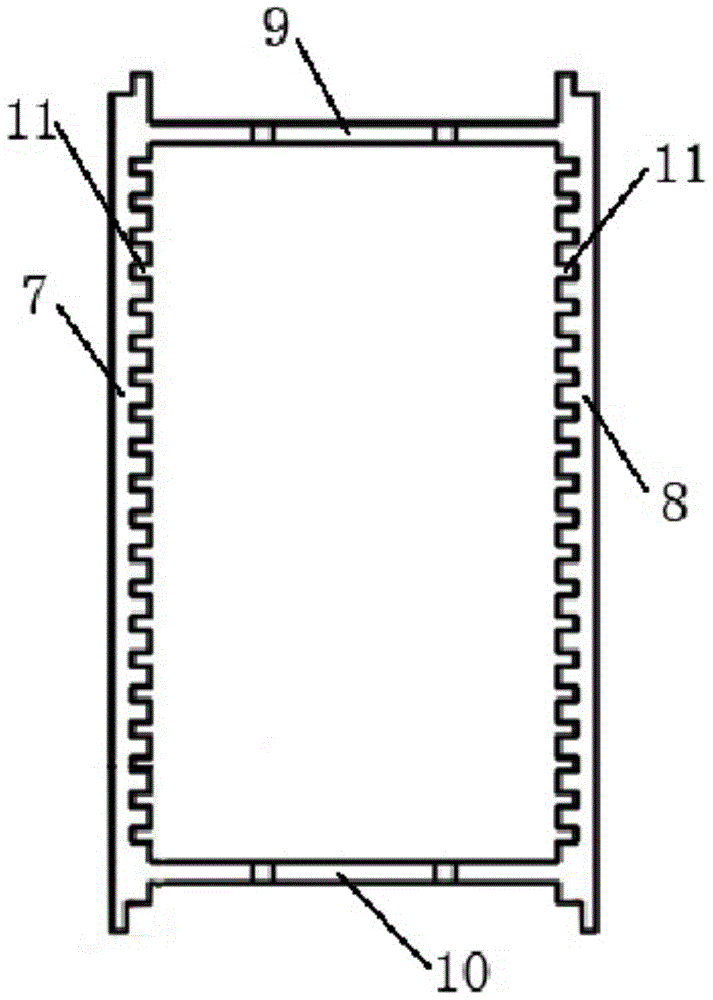

[0037] (1) Prepare the bottom sheet with the left frame strip and the right frame strip, the core particle storage tray with the core particles, and the tape-and-roll type top sheet with the bridge piece;

[0038] (2) The dispensing machine performs dispensing operations on the left frame strip and the right frame strip, so that the upper surfaces of the left frame strip and the right frame strip are glued with solder paste;

[0039] (3) Use the core particle pick-and-place mechanism to take out the core particle from the core particle storage tray and place it on the solder paste on the right frame bar;

[0040] (4) The dispensing machine applies glue to the core particles on the right frame strip, so that the upper surface of the core particles is glued with solder paste;

[0041] (5) Use the bridge pick-and-place mechanism to cut the bridge from the tape-type upper material and place it on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com