Color decomposing compound prism

A prism and anti-reflection film technology, applied in prisms, instruments, coatings, etc., can solve the problems of temperature rise of reflective display elements and damage of reflective display elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

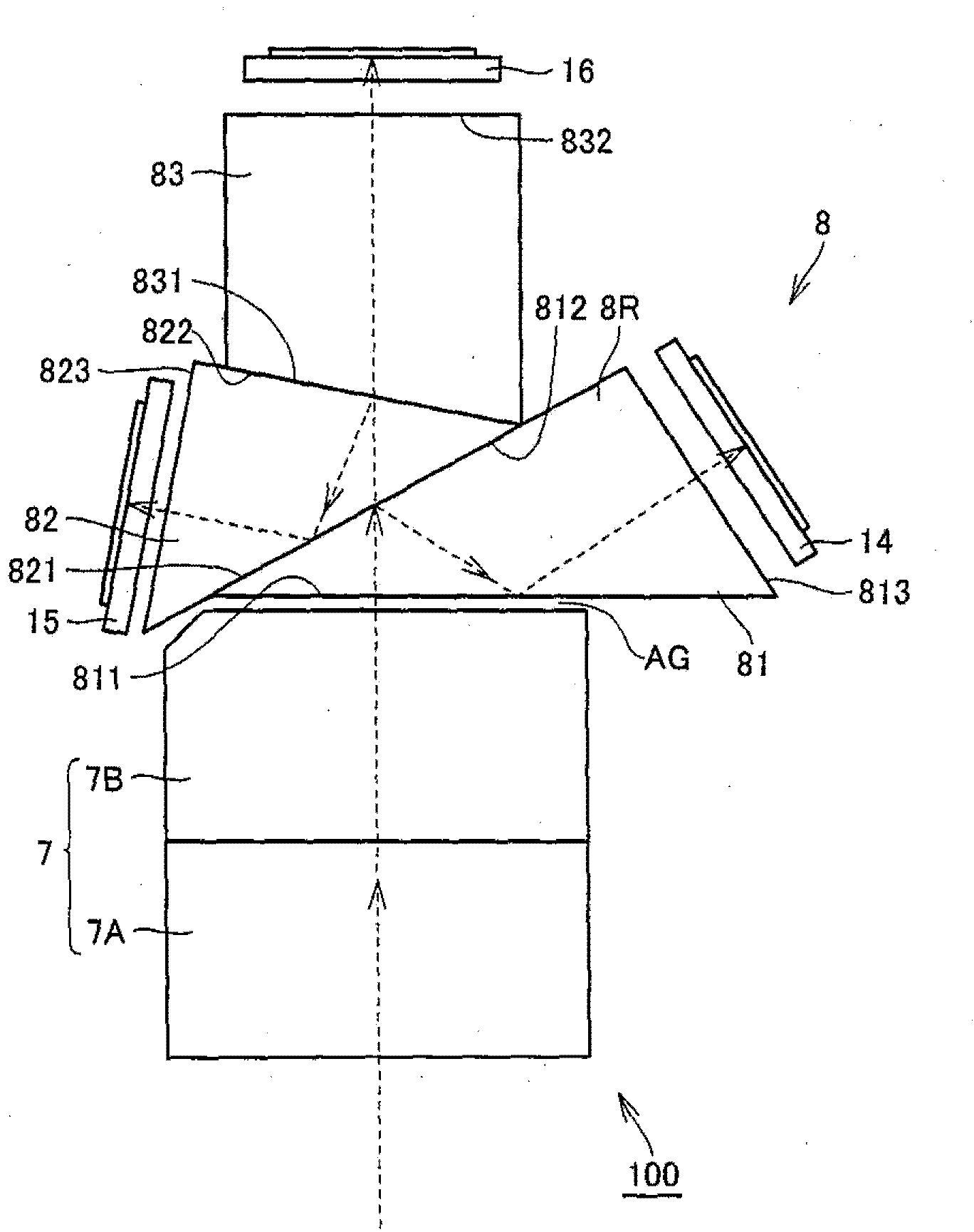

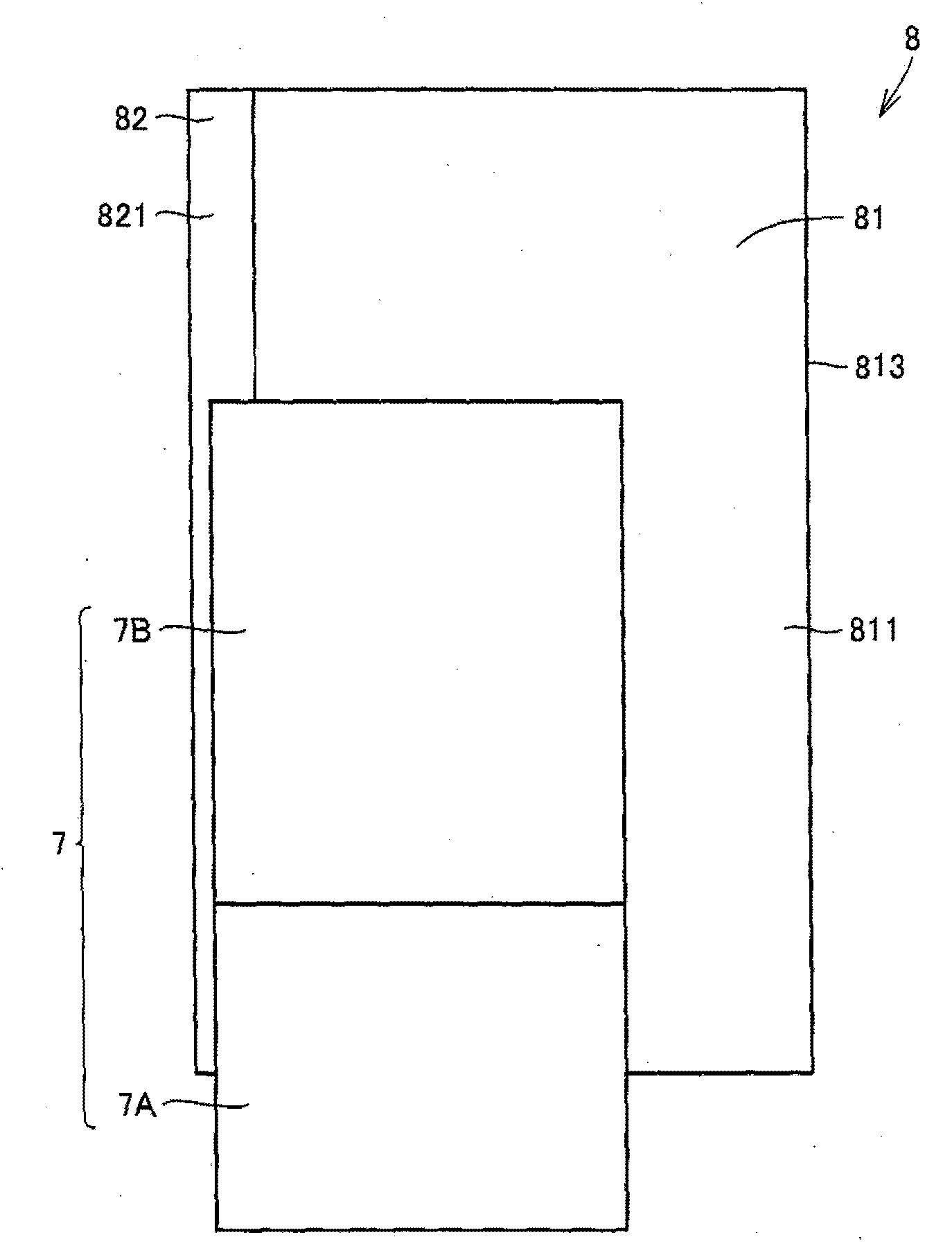

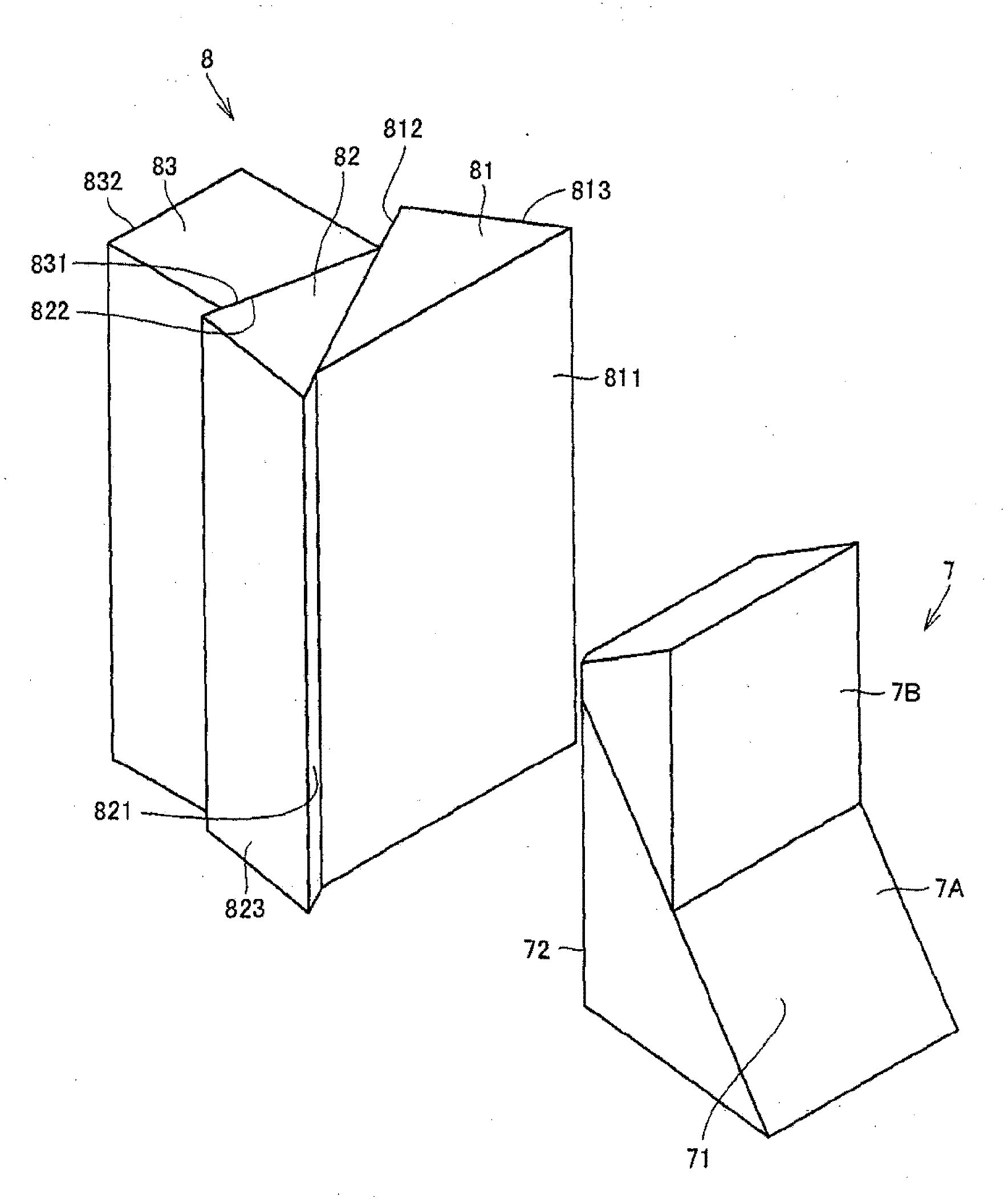

[0040] First, refer to Figure 1 to Figure 3 The basic configuration of the prism unit 100 used in the projection display device in this embodiment will be described. figure 1 is a top view of the prism unit 100, figure 2 is the front view of the prism unit, image 3 is a perspective view of the prism unit. Among them, in this specification, for the convenience of description, in Figure 1 to Figure 3 In the description, a plane parallel to the paper surface is defined as a horizontal direction, and a direction perpendicular to the paper surface is defined as a vertical direction.

[0041] (prism unit 100)

[0042]This prism unit 100 has an internal total reflection prism (TIR prism) 7 and a color separation and synthesis prism for guiding the illumination light IL to the first reflective display element 14, the second reflective display element 15, and the third reflective display element 16. 8. The prism unit 100 in this embodiment is a five prism unit.

[0043] The ...

Embodiment approach )

[0074] Next, refer to Figure 15 to Figure 19 The case where another antireflection film is used will be described. Figure 15 It is a figure showing another film structure of the antireflection film formed on each prism end face, Figure 16 It is a graph showing the refractive index of the film constituent material of the antireflection film with respect to each wavelength.

[0075] in addition, Figure 17 is used Figure 15 In the case of the anti-reflection coating for blue light whose peak wavelength of light is 465nm, the graph shows the results of measuring the reflectance in the range of angle of incidence (AOI) from 0° to 60°, Figure 18 is used Figure 15 In the case of the anti-reflection coating for green light with a peak wavelength of light of 532nm shown, the graph shows the results of measuring the reflectance in the range of angle of incidence (AOI) from 0° to 60°, Figure 19 is used Figure 15 In the case of the anti-reflection coating for red light whos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com