Method for stimulating goaf ignition process under U-shaped ventilation

A simulation method and process simulation technology, applied in the field of mining engineering, can solve the problem of non-spontaneous development process reaction and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

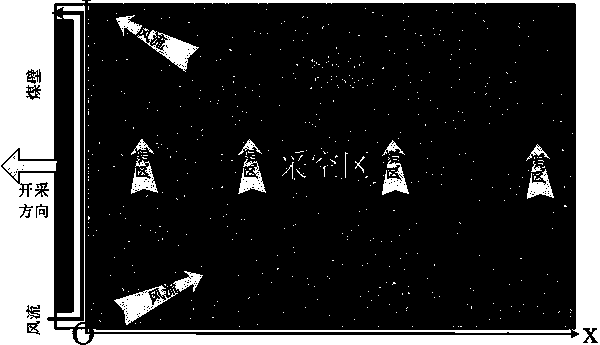

[0042] In a mine, the 18305 mining face is 200 m long and 4.8 m high. Taking this working face as an example, the numerical simulation of goaf spontaneous combustion under U-shaped ventilation is carried out. The depth of the goaf is taken as 300m, the normal advancing speed of the working face is about 3.6 m / d, the ventilation resistance is 58 Pa, the inclination angle is 5°, and the maximum air volume of the working face is 700~810m 3 / min, the inlet air temperature is 19°C, the original rock temperature is 21.7°C, and the average thickness of residual coal is 0.4 m during normal advance. model such as figure 1 shown. The origin of the model is the gob (point O) in the lower left corner, the X-axis direction is from left to right (horizontal), and the Y-axis direction is from bottom to top (vertical).

[0043] Using PFC3D to simulate oxygen in the remaining coal seam, three problems need to be solved: 1) the oxygen in the air is equivalent to particles in proportion, 2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com