Rail vehicle curve passage capacity testing method

A capability test, rail vehicle technology, applied in the direction of railway vehicle testing, etc., can solve the problem that the suspension system and stress conditions cannot be fully considered, and achieve the effect of ensuring the safe operation of high-speed railways, ensuring test results, and saving test funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

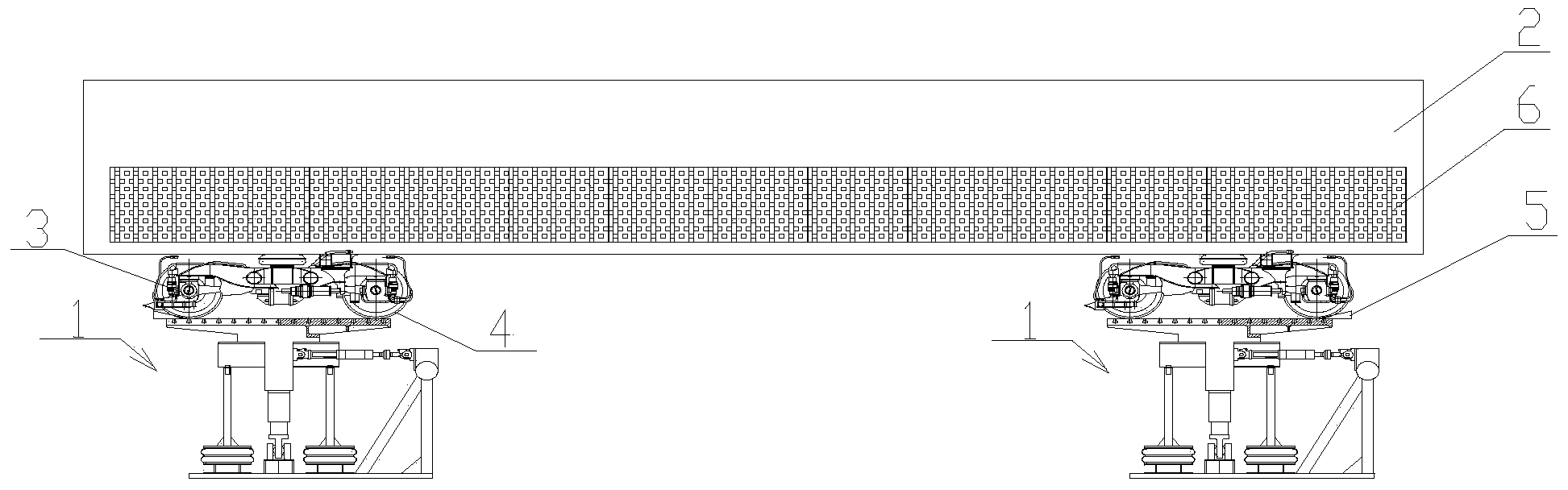

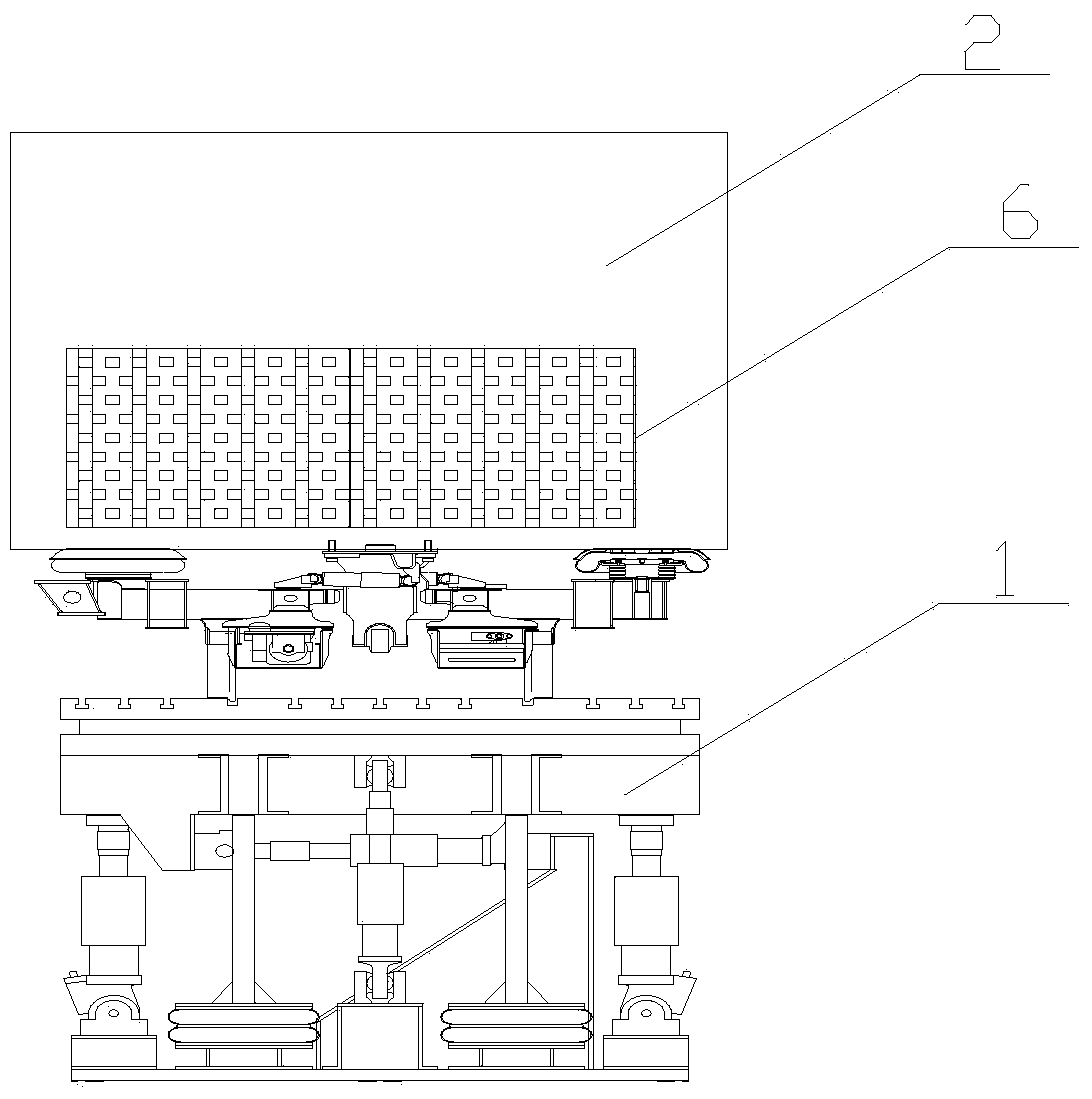

[0035] Such as figure 1 with figure 2 As shown, a rail vehicle curve passing performance test method is carried out on the test platform 1, the test platform 1 is four, and the train 2 to be tested is two rows, and two test platforms 1 are equipped with respect to each train 2, each The test platform 1 is set corresponding to a bogie 3, and each bogie 3 falls on the corresponding test platform 1 during the test, and the distance between the two trains 2 is arranged according to the actual trailer state.

[0036] During the test, a counterweight device is placed inside the train 2. In the present embodiment, the counterweight device preferably adopts a counterweight 6, and a number of counterweights 6 varying in number are installed inside the train 2. By placing counterweights of different weights, The weight 6 can simulate the actual state o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com