A system that significantly reduces the temperature of district heating for combined heat and power generation

A central heating and combined heat and power generation technology, applied in hot water central heating systems, heating systems, household heating, etc., can solve the problem that the latent heat of vaporization cannot be fully utilized, so as to improve energy utilization efficiency and improve The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

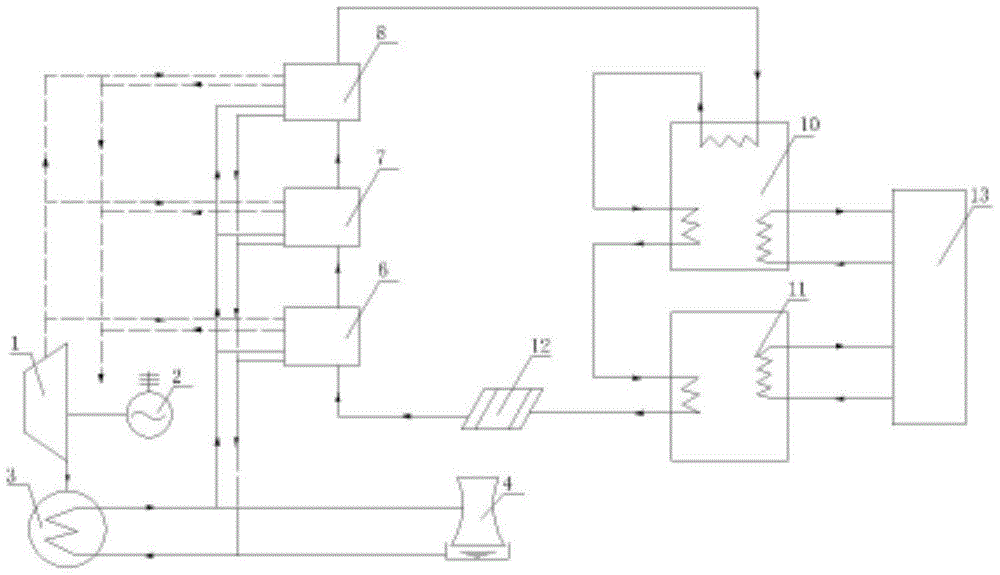

[0017] In a thermal power plant, a part of the high-temperature steam in the steam turbine 1 drives the generator 2 to generate electricity, and the other part of the high-temperature steam is respectively input to the steam double-effect absorption heat pump 6, the steam single-effect absorption heat pump 7, and the steam large temperature difference absorption heat pump 8, as The power source of the absorption heat pump unit participates in heat exchange;

[0018] The exhaust steam in the steam turbine 1 enters the condenser 3, and the 40°C hot water after heat exchange is connected in parallel to the steam double-effect absorption heat pump 6, the steam single-effect absorption heat pump 7, and the steam large temperature difference absorption heat pump The heat pump 8, as the low-temperature heat source of the absorption heat pump units at all levels, returns to the condenser 3 after heat exchange;

[0019] In the heat exchange station, the primary network water supply at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com