A pipe holding device

A technology for clamping devices and pipes, applied in packaging, transportation and packaging, external frames, etc., can solve problems such as loss, oil elbow shaking, cable breakage, etc., to reduce wear, improve service life, and facilitate maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

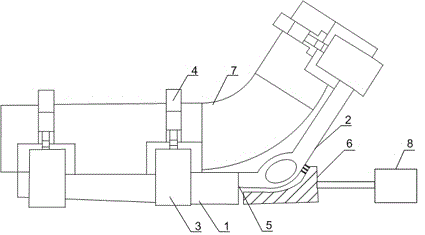

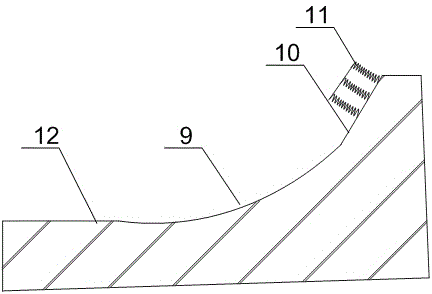

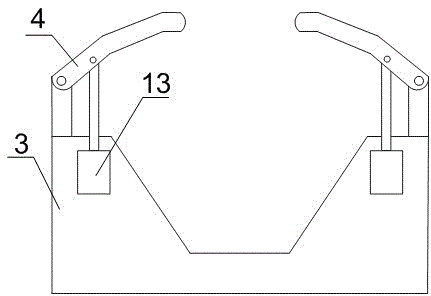

[0023] like Figure 1 to Figure 3 As shown, a pipe clamping device of the present invention includes a bottom plate 1 and an adjusting plate 2 arranged obliquely, a connecting plate 5 is arranged at the end of the bottom plate 1, and the bottom end of the connecting plate 5 and the adjusting plate 2 Hinged, fixed block 3 is installed on the bottom plate 1 and the adjustment plate 2, the fixed block 3 is U-shaped, the fixed block 3 is connected with the bottom plate 1 and the adjustment plate 2 by bolts, and also includes a pressure plate 4, the pressure plate 4 is hinged with the upper end of the fixed block 3, and a hydraulic cylinder 13 is also installed in the fixed block 3, and the telescopic end of the hydraulic cylinder 13 is connected with the middle part of the pressure plate 4. A limit mechanism is also provided; the limit mechanism includes a limit base 6 and a cylinder 8, and the limit base 6 is provided with an inclined surface 10 and a horizontal surface 12, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com