Roof support structure and excavator

A technology of support structure and machine top cover, which is applied in the direction of earth mover/excavator, construction, etc., can solve the problems of limited telescopic stroke of gas spring, large space required for folding and unfolding, and difficulty in further adjustment, so as to achieve convenient Ease of adjustment and maintenance, and the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention. In addition, the embodiments in this section and the features in the embodiments can be combined with each other under the condition of no conflict.

[0044] Please refer to Figure 1 to Figure 4 , the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

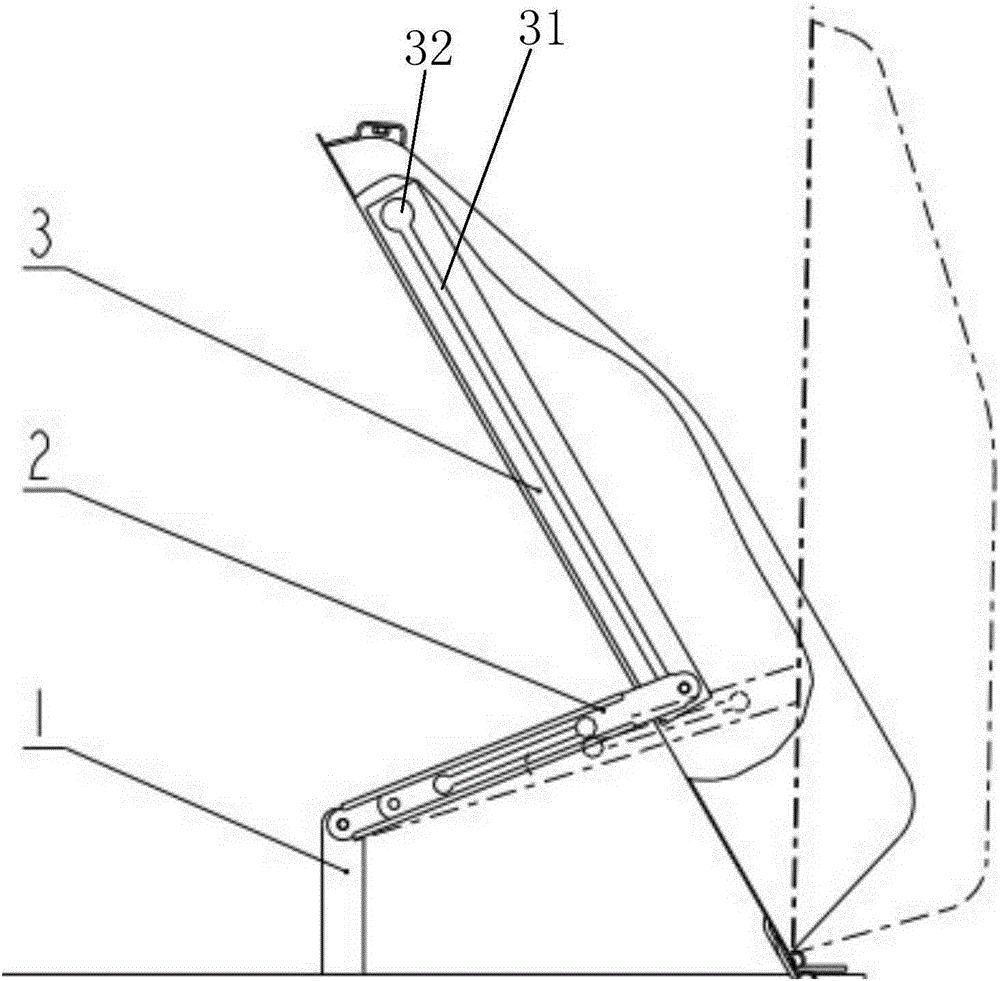

[0045] combine image 3 As shown, the roof cover support structure of this embodiment includes a support body 1 , a roof cover 3 and a strut 2 .

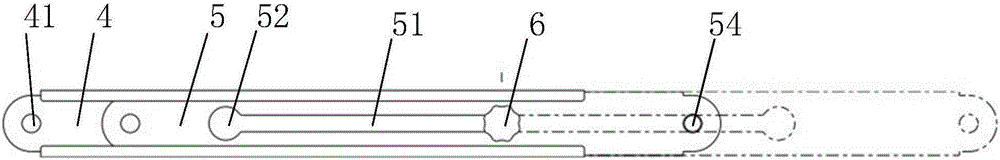

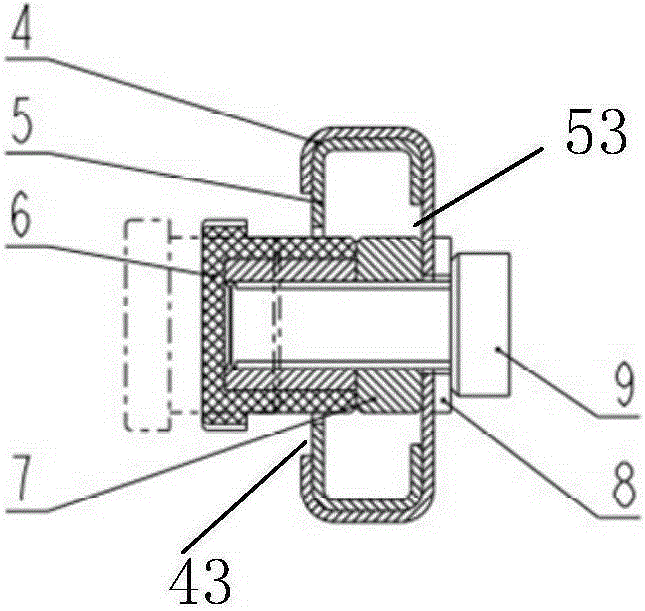

[0046] combine figure 1 and 2 As shown, the strut 2 further includes a first rod 4 , a second rod 5 , a locking knob 6 , a nut 7 and a bolt 9 .

[0047] Among them, the first rod 4 is in a half-engagement shape, forming an inner slide rail structure with a first engagement gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com