Spraying structure provided washing machine inner cover and washing machine comprising same

A washing machine inner cover and washing machine technology, applied in the field of washing machines, can solve the problems of unstable water flow, high cost, large water flow, etc., and achieve the effect of improving washing efficiency and cleaning ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

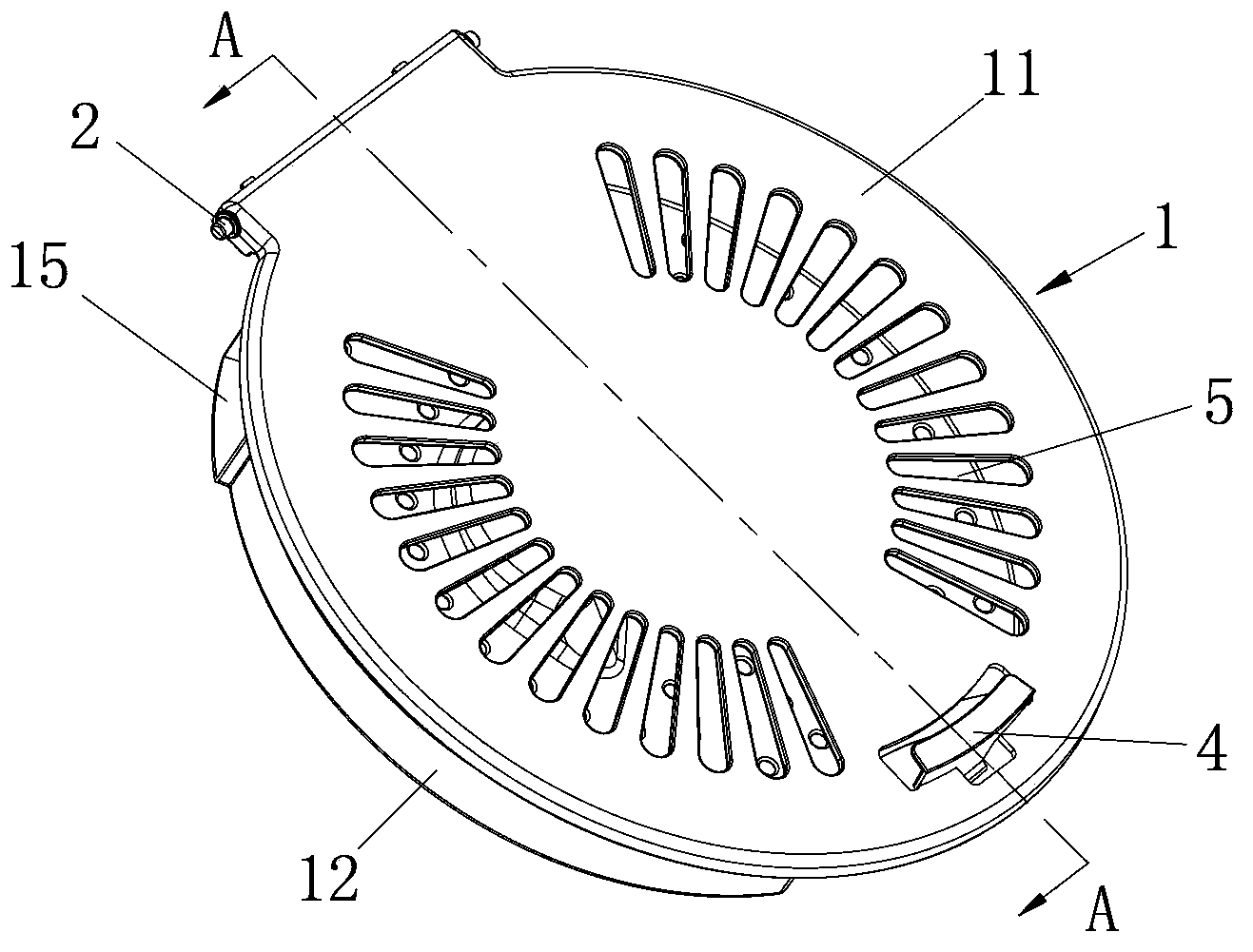

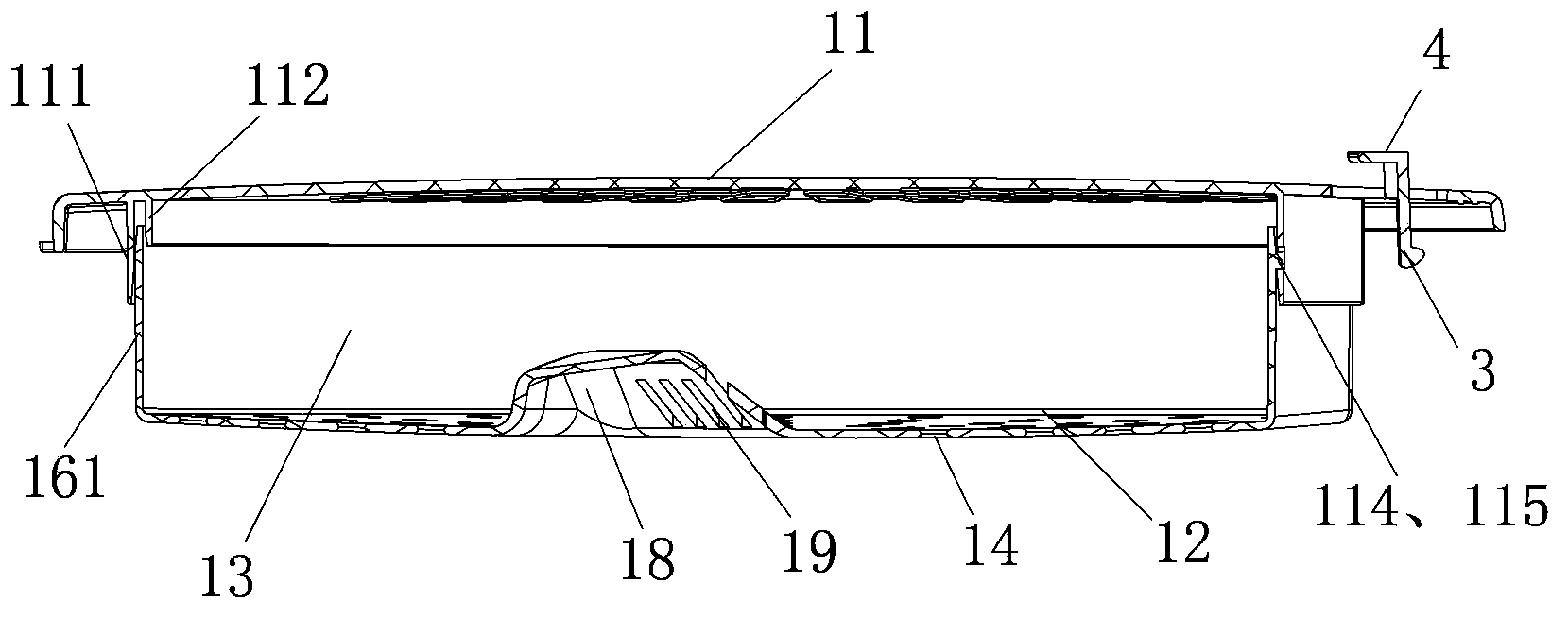

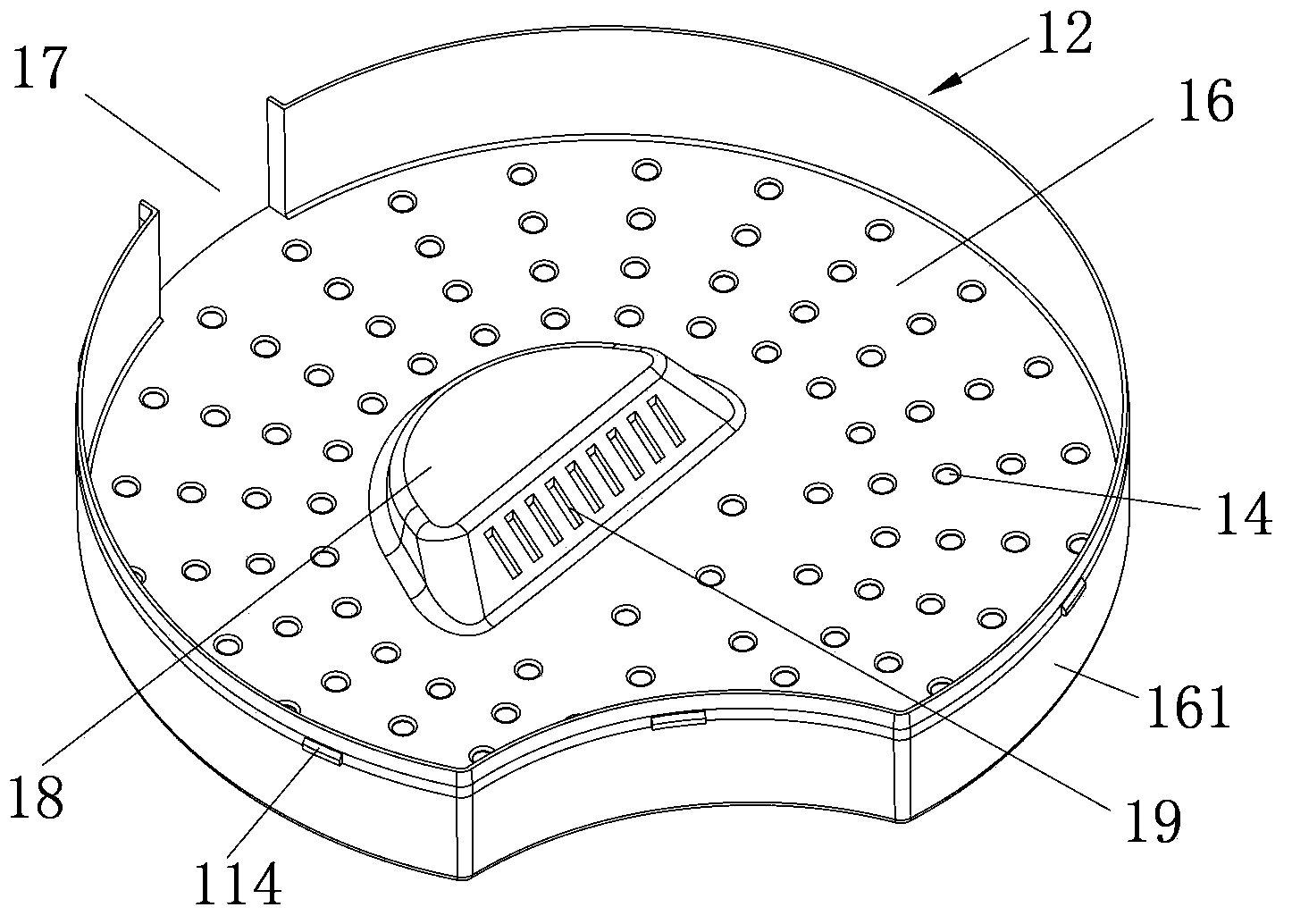

[0048] like Figure 1 to Figure 5 As shown, the inner cover 1 described in this embodiment includes an upper cover 11 and a lower cover 12, the lower surface of the upper cover 11 is provided with an annular rib 111 matching the opening of the lower cover groove 16, and the inner side of the annular rib 111 is provided with at least A section of positioning rib 112, the groove opening of the lower cover is plugged into the inside of the annular rib 11, sandwiched between the annular rib 111 and the positioning rib 112 (see figure 2 ).

[0049] Wherein, the opening of the annular rib 111 and the positioning rib 112 corresponding to the groove peripheral wall 161 is provided with a rib gap 113, and the groove gap 17 and the rib gap 113 together constitute the opening of the side wall of the spray water chamber. , that is, the inner cover water inlet 15.

[0050] The upper cover 11 and the lower cover 12 described in this embodiment are connected by a buckle structure, the out...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that the upper cover and the lower cover constituting the inner cover are connected by threads, specifically, the outer side of the groove opening of the lower cover is provided with external threads, and the annular rib of the upper cover is provided with internal threads (in the figure not shown).

[0055] In the above-mentioned first and second embodiments, the groove opening of the lower cover may also be set on the outer ring of the annular rib of the upper cover, and then connected by a buckle structure or a thread structure.

Embodiment 3

[0057] like Figure 6 to Figure 10 As shown, the structure and connection method of the upper cover 11 and the lower cover 12 described in this embodiment are different from those in Embodiment 1. The groove opening of the lower cover is provided with an annular flange 6 outward, and the upper cover 11 is fastened in the concave On the groove opening, the groove gap 17 alone constitutes the opening of the side wall of the spray water chamber, that is, the water inlet 15 of the inner cover.

[0058] The upper cover 11 is connected to the lower cover 12 through a rotating buckle structure, the inner edge of the annular flange 6 is provided with a buckle groove 162 lower than the opening of the groove, and the lower surface edge of the upper cover 11 is provided with at least three groups Shaped card protrusion 116, the card protrusion 116 protrudes from the lower surface of the upper cover and has a bayonet 118 on the side, and the corresponding card protrusion 116 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com