Automatic overturning device of hosiery machine

An automatic turning and hosiery machine technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of reducing production efficiency, occupying workers' time, and difficulty in recruiting workers, reducing production costs, improving production efficiency, Reduce the effect of manual turning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

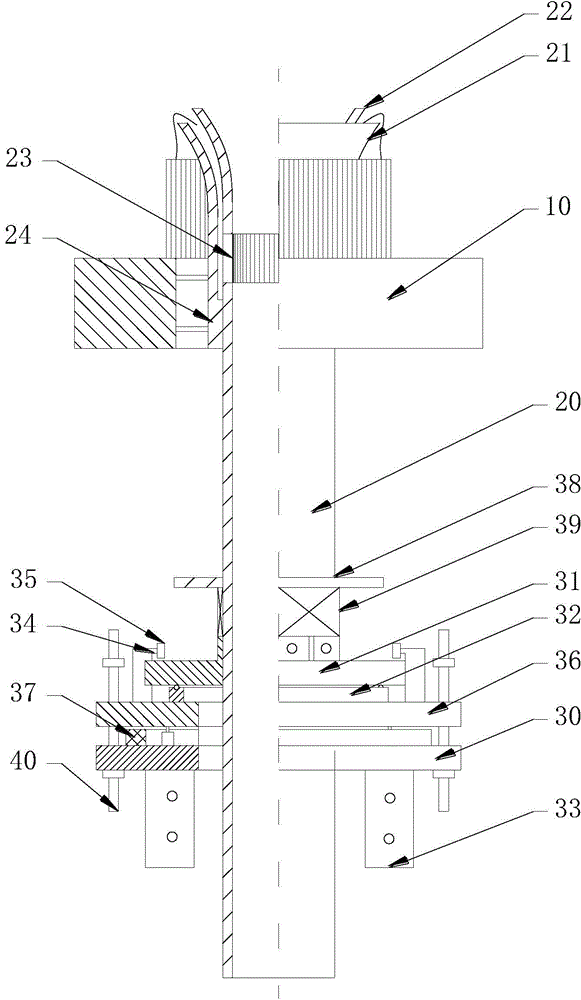

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] An automatic overturning device for a sock knitting machine according to the present invention includes a cylindrical needle cylinder mechanism 10 and a suction pipe 20 connected to the sock outlet pipe. The suction pipe 20 coincides with the vertical projection of the center of the needle cylinder mechanism 10 A base plate 30 is arranged under the needle cylinder mechanism 10, and the needle cylinder mechanism 10 and the base plate 30 are respectively connected to the main body of the sock knitting machine.

[0023] The syringe mechanism 10 is provided with an outer horn tube 21 with a large upper mouth and a small lower mouth. The outer horn tube 21 is provided with an inner horn tube 22 matched with it. The preferred cross sections of the outer horn tube 21 and the inner horn tube 22 in the present invention are Ratio is the same, the diameter of the upper op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com