A kind of preparation method of industrialized production gadopentetate dimeglumine

A technology of gadopentetate meglumine and pentetic acid is applied in the preparation of meglumine pentetate and the field of high-purity magnetic resonance imaging MRI contrast agent, which can solve the problem that the patient's demand for drug development cannot be met, and it is difficult to realize industrialized production. life safety hazards and other issues, to achieve the effect of reducing quality risks, shortening working hours, and avoiding minor changes in proportions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

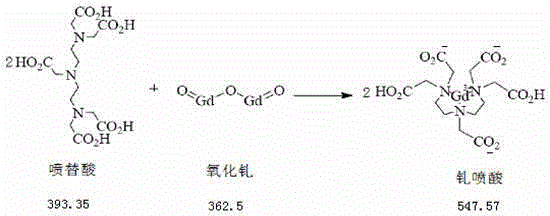

[0024] Step 1: Preparation of gadopentetate

[0025] Dissolve 27.08Kg of gadolinium oxide and 58.72Kg of pentetic acid in 215 liters of purified water at room temperature, heat the feed solution to 93-96°C, keep stirring and react for 6-10 hours until the reaction solution is clear, and obtain gadolinium-diethylenetriamine Pentaacetic acid solution;

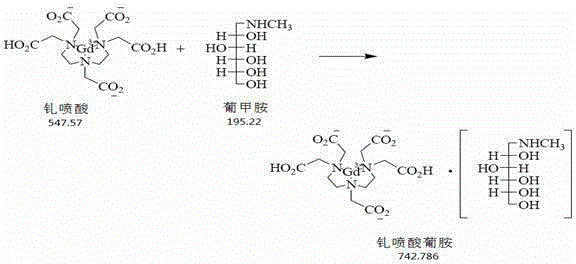

[0026] Step 2: Preparation of gadopentetate meglumine

[0027] Dissolve 29.15Kg of meglumine into 73 liters of purified water at room temperature to obtain an aqueous solution of meglumine for subsequent use;

[0028] After cooling the gadolinium-diethylenetriaminepentaacetic acid solution to room temperature, add an aqueous solution of meglumine, and then stir and react at room temperature for 2 to 3 hours to prepare the gadopentetate meglumine solution;

[0029] After the reaction, add 1.5Kg of activated carbon to the above gadopentetate meglumine solution, stir for 30 minutes, filter, and then concentrate under reduced press...

Embodiment 2

[0033] Step 1: Preparation of gadopentetate

[0034] Dissolve 27.08Kg of gadolinium oxide and 58.72Kg of pentetic acid in 215 liters of purified water at room temperature, heat the feed solution to 90-94°C, keep stirring for 6-10 hours until the reaction solution is clear, and obtain gadolinium-diethylenetriamine Pentaacetic acid solution;

[0035] Step 2: Preparation of gadopentetate meglumine

[0036] Dissolve 29.15Kg of meglumine into 73 liters of purified water at room temperature to obtain an aqueous solution of meglumine for subsequent use;

[0037] After cooling the gadolinium-diethylenetriaminepentaacetic acid solution to room temperature, add meglumine aqueous solution, then stir and react at room temperature for 2 hours to prepare the gadopentetate meglumine solution;

[0038] After the reaction is over, add 1.5Kg of activated carbon to the feed liquid, stir for 30 minutes and then filter, wash the activated carbon with 20 liters of purified water, combine the filt...

Embodiment 3

[0042] Step 1: Preparation of gadopentetate

[0043] Dissolve 27.08Kg of gadolinium oxide and 58.72Kg of pentetic acid in 215 liters of purified water at room temperature, heat the feed solution to 94-98°C, keep stirring for 6-10 hours until the reaction solution is clear, and obtain gadolinium-diethylenetriamine Pentaacetic acid solution;

[0044] Step 2: Preparation of gadopentetate meglumine

[0045] Dissolve 29.15Kg of meglumine into 73 liters of purified water at room temperature to obtain an aqueous solution of meglumine for subsequent use;

[0046] After cooling the gadolinium-diethylenetriaminepentaacetic acid solution to room temperature, add meglumine aqueous solution, then stir and react at room temperature for 2 hours to obtain gadopentetate meglumine solution;

[0047] After the reaction, add 1.5Kg of activated carbon to the above gadopentetate dimeglumine solution, stir for 30 minutes, filter, and then concentrate under reduced pressure at an external temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com