Carrying device

A technology of handling device and link mechanism, which is used in transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc. Agility, increased service life, increased strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

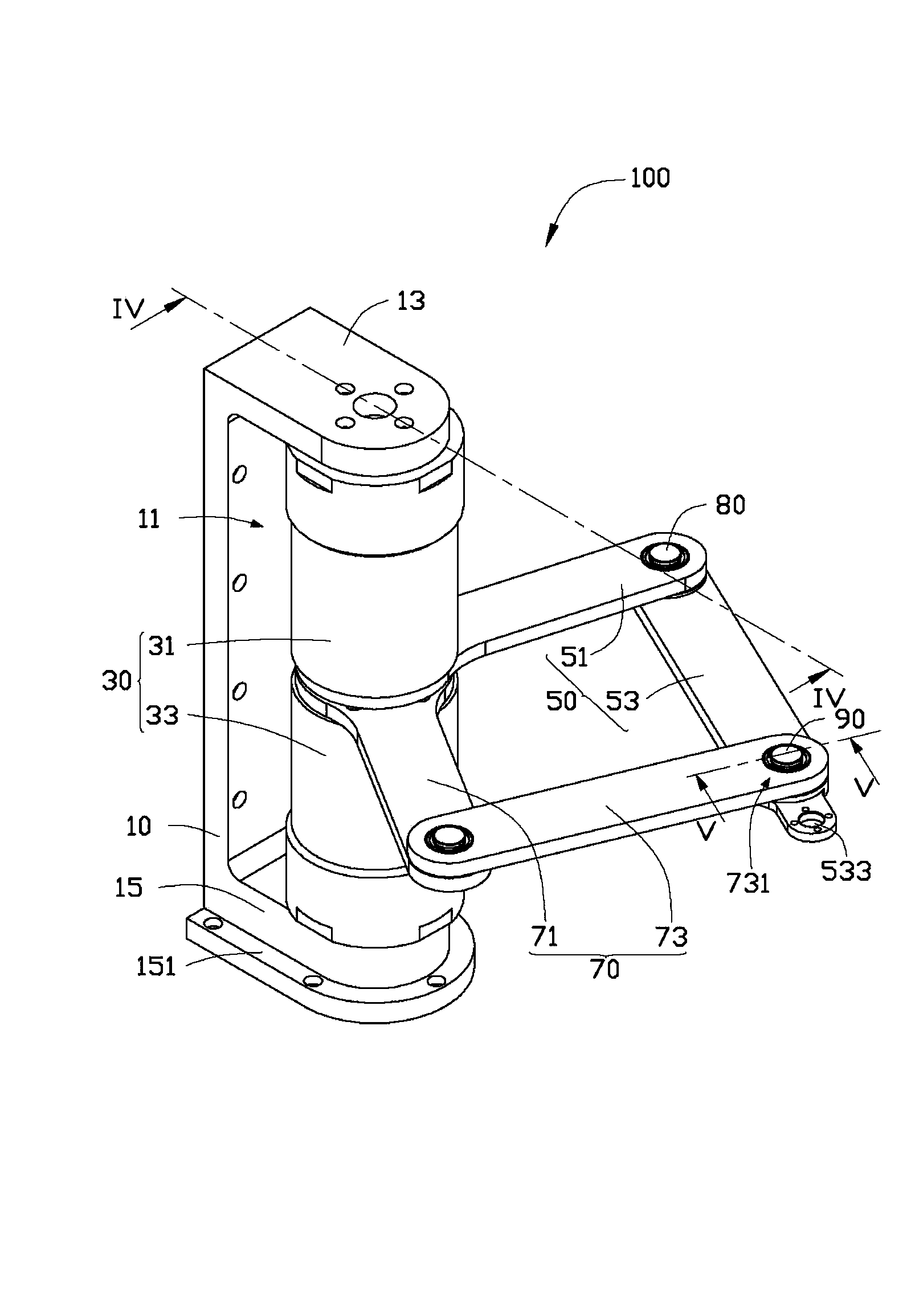

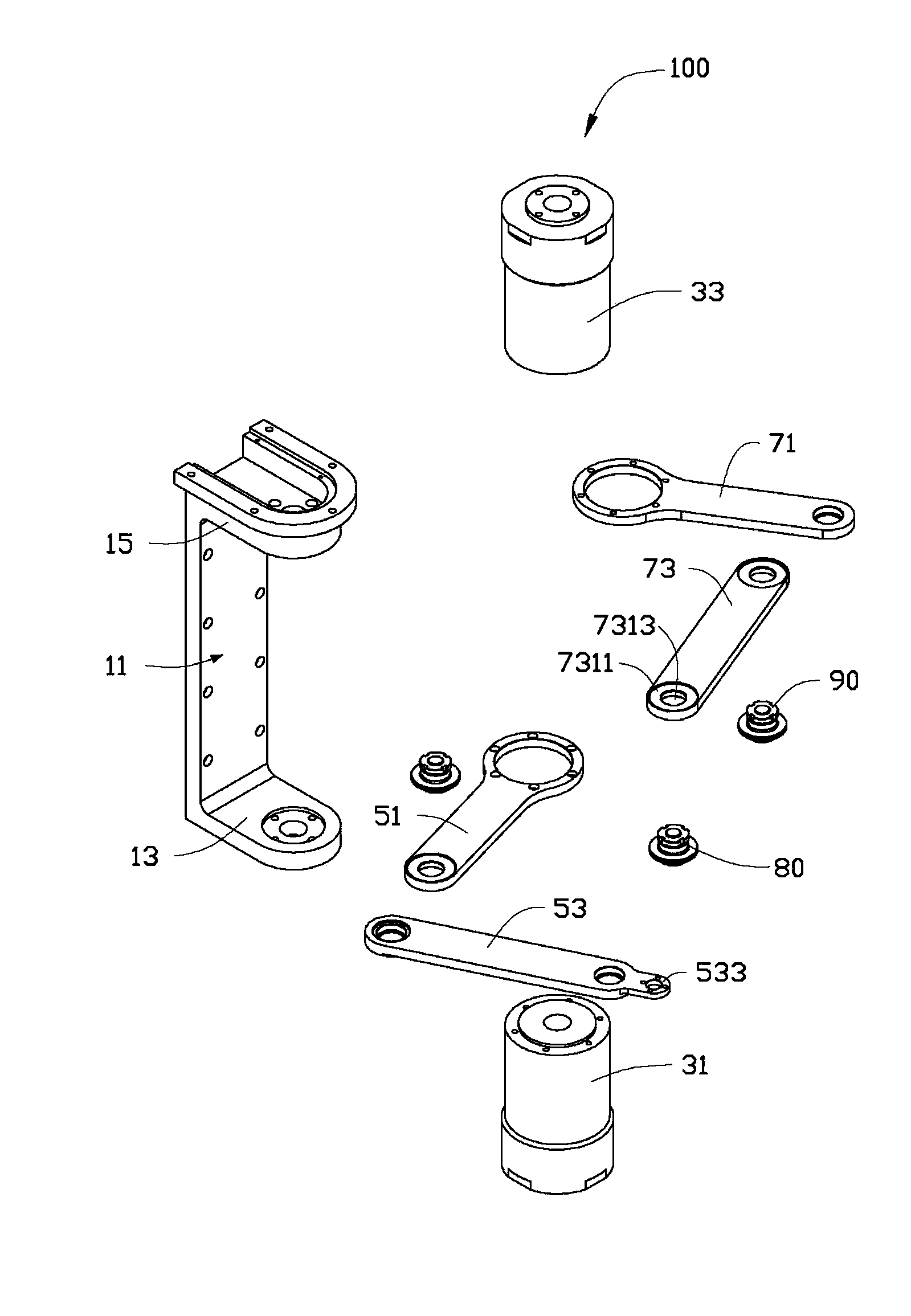

[0014] see figure 1 and figure 2 , the conveying device 100 of this embodiment is connected to the end of the mechanical arm (not shown), and is used for conveying the workpiece (not shown). The transporting device 100 includes a fixing base 10 , a driving assembly 30 , a first link mechanism 50 , a second link mechanism 70 and a pivot assembly 90 . The driving assembly 30 is mounted on the fixing base 10 , and the first link mechanism 50 and the second link mechanism 70 are fixedly connected to the driving assembly 30 respectively, and are pivotally connected together by a pivot assembly 90 .

[0015] Please also see image 3 , the fixed seat 10 is roughly in the shape of ㄈ, which is fixedly connected with the end of the mechanical arm. The fixing base 10 includes a first fixing portion 13 and a second fixing portion 15 opposite to each other. The first fixing portion 13 and the second fixing portion 15 jointly form a receiving space 11 for receiving the driving assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com