Method and device for cleaning away coal slime in grooves of belt

A belt and coal cleaning technology, which is applied in the direction of transportation and packaging, conveyor objects, rollers, etc., can solve the problems of reduced belt friction, unclean cleaning, and inconvenient work, so as to prevent belt deviation and improve processing Convenience and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

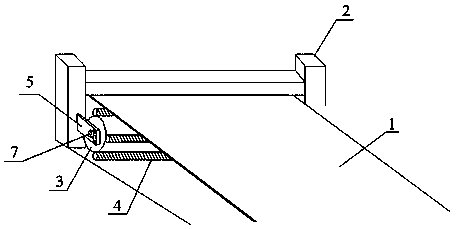

[0014] Look figure 1 , figure 1 The schematic diagram of the overall structure of the present invention is shown, and as can be seen from the figure, the core technical solution of the present invention is to set a supporting roller 3 at the bottom of the belt 1 before the H frame 2 of the belt conveyor, and the surface of the supporting roller 3 is longitudinally spaced at least Two back ribs 4 (four evenly distributed in the figure), thus forming a convex-concave-convex structure on the surface of the idler 3, when the idler 3 rotates with the belt 1 at the bottom of the belt 1 , the idler roller 3 will produce a lifting-relaxing-lifting cycle force on the belt 1, so that the belt 1 is beaten rhythmically, so that the slime in the groove of the belt 1 is continuously cleaned.

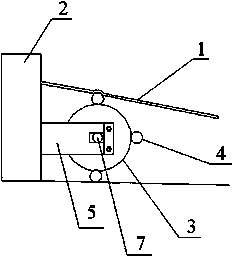

[0015] From figure 2 It can be seen that the position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com