Automobile body and auxiliary frame installing structure

A technology for mounting structure and automobile body, applied in the connection between the body and the frame, vehicle components, transportation and packaging, etc., can solve the problems of high bolt tightening force, follow-up rotation of bolts, crushing, etc., to improve assembly Efficiency, improving assembly strength, and simplifying the effect of assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

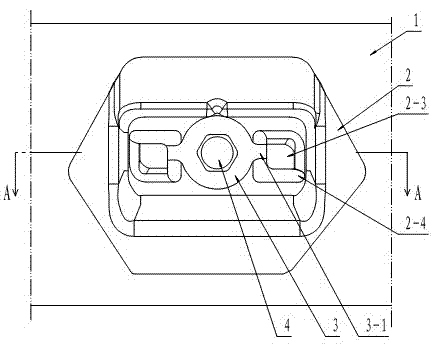

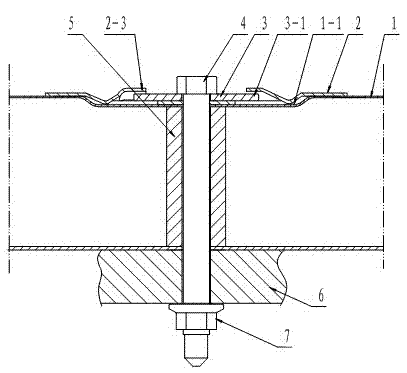

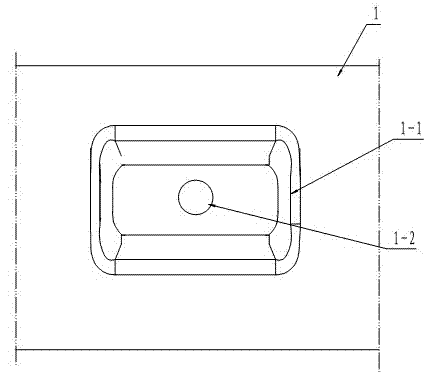

[0019] see figure 1 , figure 2 , The mounting structure of the present invention includes a vehicle body 1 , a subframe 6 , subframe connecting bolts 4 and nuts 7 . The subframe connecting bolts pass through the vehicle body and the subframe and are screwed with the nut 7 to fix the vehicle body and the subframe. The body 1 is a hollow thin-walled part, and a bolt sleeve 5 is arranged between the upper wall and the lower wall of the body. On the one hand, the bolt sleeve guides the penetration of the connecting bolts of the sub-frame, and on the other hand, prevents the connection of the sub-frame. The body deforms severely when the bolts are tightened.

[0020] see Figure 1-4 , in order to increase the connection strength of the subframe connecting bolts on the vehicle body and prevent the subframe connecting bolts from rotating when tightened, the present invention makes the following improvements: stamp out grooves 1-1 on the vehicle body, bolt mounting holes 1- 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com