Nonwoven fabric composite sound-absorbing lamination fabric for automobile internal decoration and manufacturing method thereof

A technology for automotive interiors and non-woven fabrics, applied in chemical instruments and methods, vehicle parts, synthetic resin layered products, etc., can solve problems such as car noise that plagues safe driving, achieve significant sound-absorbing functions, reduce traffic accidents, reduce The effect of noise levels in the car interior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

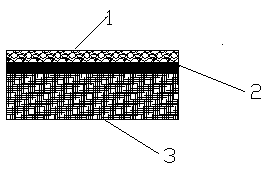

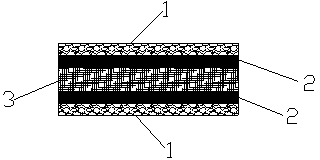

[0029] Example 1: Such as figure 1 As shown,

[0030] A composite sound-absorbing laminated fabric of non-woven fabric for automobile interior decoration, comprising: expanded polytetrafluoroethylene film layer or expanded polytetrafluoroethylene modified film layer 1, connecting layer 2 and nonwoven fabric for automobile interior decoration The cloth layer 3, the connecting layer 2 is a PU polyurethane adhesive bonding layer, and its manufacturing method specifically includes the following steps:

[0031] The non-woven fabric layer 3 and the expanded polytetrafluoroethylene film layer or the expanded polytetrafluoroethylene modified film layer 1 for automobile interior decoration are unrolled on the coating machine, and the speed of the coating machine is 8-20m / min, apply PU polyurethane adhesive on the expanded polytetrafluoroethylene film layer or expanded polytetrafluoroethylene modified film layer 1 with a coater roller, and then dry it at a temperature of 70℃~100℃, Laminate...

Embodiment 2

[0032] Example 2: Such as figure 1 As shown,

[0033] A composite sound-absorbing laminated fabric of non-woven fabric for automobile interior decoration, comprising: expanded polytetrafluoroethylene film layer or expanded polytetrafluoroethylene modified film layer 1, connecting layer 2 and nonwoven fabric for automobile interior decoration Cloth layer 3, the connecting layer 2 is a low-melting plastic hot-melt micropowder fusion fusion layer, and its manufacturing method specifically includes the following steps:

[0034] The non-woven fabric layer 3 and the expanded PTFE film layer or the expanded PTFE modified film layer 1 for automobile interior decoration are unrolled on the heat sealing machine, and the speed of the heat sealing machine is 8-20m / min, in the car The decorative nonwoven fabric layer 3 and the expanded polytetrafluoroethylene film layer or the expanded polytetrafluoroethylene modified film layer are sprayed with hot-melt low-melting plastic hot-melt micropowder...

Embodiment 3

[0035] Example 3: Such as figure 1 As shown,

[0036] A composite sound-absorbing laminated fabric of non-woven fabric for automobile interior decoration, comprising: expanded polytetrafluoroethylene film layer or expanded polytetrafluoroethylene modified film layer 1, connecting layer 2 and nonwoven fabric for automobile interior decoration Cloth layer 3, the connecting layer 2 is a low-density gram-weight non-woven fabric hot-melt fusion layer, and its manufacturing method specifically includes the following steps:

[0037] Unwind the nonwoven fabric layer 3 for automobile interior decoration, the expanded PTFE film layer or the expanded PTFE modified film layer 1, and the low-density non-woven fabric on the heat sealing machine. The speed of the heat sealing machine is 8 ~20m / min. Lay a low-density gram-weight non-woven fabric between the expanded polytetrafluoroethylene film layer or expanded polytetrafluoroethylene modified film layer 1 and the non-woven fabric layer 3 for aut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com