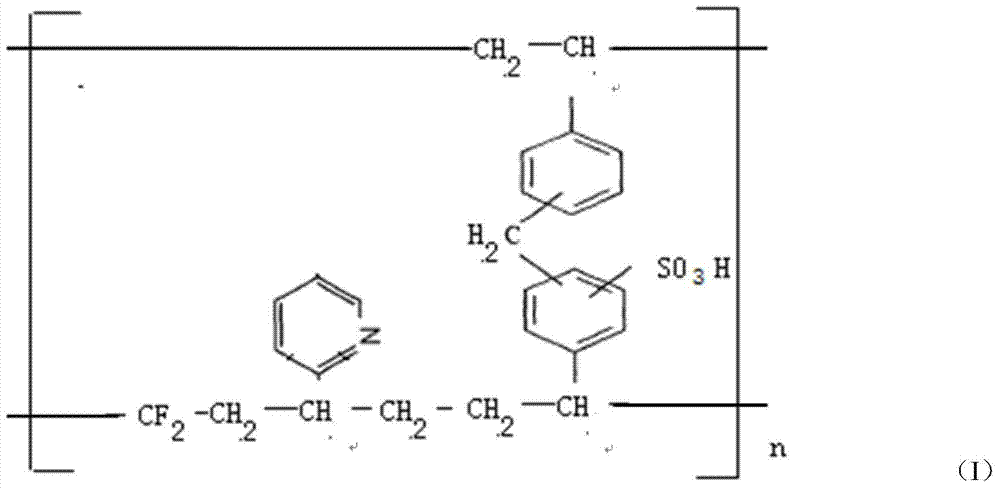

Post-ether carbon-four polymerized catalyst as well as preparation method and application thereof

A post-ether C4 catalyst technology, which is applied in the field of post-ether C4 stack catalysts and its preparation, can solve the problems of resin catalysts not being resistant to high temperature, easy falling off of sulfonic acid groups, poor catalytic activity, etc., and achieve good stability , high catalytic activity, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1). Suspension polymerization:

[0030] 1.1) Preparation of water phase:

[0031] In parts by weight, add 100 parts of water, 0.5 parts of polyvinyl alcohol, and 2 parts of inorganic dispersants into the reactor, and stir evenly;

[0032] 1.2) Preparation of oil phase:

[0033] In parts by weight, 100 parts of styrene and 10 parts of divinylbenzene monomers are added with vinylidene fluoride accounting for 3% of the total monomer percentage and 2-vinylpyridine accounting for 1% of the total monomer percentage Participate in polymerization, then add 2 parts of benzoyl peroxide, 35 parts of liquid wax, and stir evenly;

[0034] 1.3) Suspension polymerization:

[0035] Add the oil phase solution prepared in step 1.2) to the reaction kettle with the prepared water phase in step 1.1), stir, then react at 70°C for 16 hours, discharge after the reaction, and wash the obtained polymerized white balls to The water is clear, and the porogen is extracted after drying.

[0036...

Embodiment 2

[0039] In step 1.2), vinylidene fluoride accounting for 1% of the total amount of monomers is added, and the other steps are exactly the same as in Example 1, and the sample number is M02.

Embodiment 3

[0041] In step 1.2), add vinylidene fluoride accounting for 5% of the total amount of monomers, and the other steps are exactly the same as in Example 1, sample number M03.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com