A method for manufacturing a simulation tunnel deformation experiment model

An experimental model and roadway technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of uneven roadway walls, inconvenient drilling, and movement of anchor rod components, etc., to achieve smooth and tidy roadway surfaces, beautiful models, and easy installation of pallets and nuts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] The model preparation method of simulation roadway deformation experiment of the present invention, concrete steps are as follows:

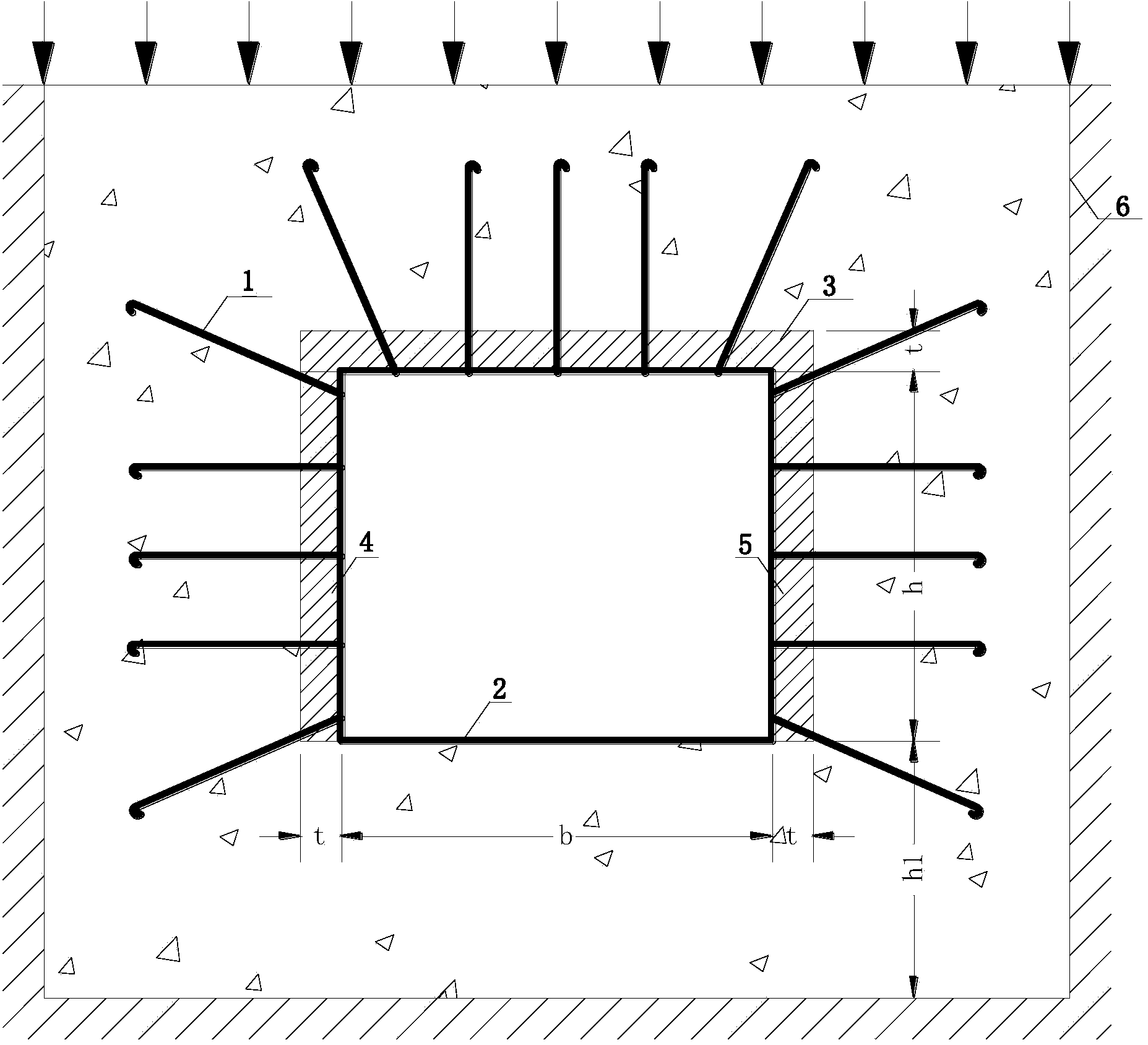

[0019] a. Use the model box 6 to fill the simulation material into the model box 6. When the filling simulation material in the model box 6 is filled to the set position h1, the set position h1 is about 1 / 5 of the height of the model box. According to the experimental design Determine, set the position of the simulated roadway in the middle of the model box 6, place the simulated roadway element 2 whose width is b and the height is h, the section of the simulated roadway element 2 is a rectangular cylindrical body, on the left side of the simulated roadway element 2, The right side is provided with the left side plank 4, the right side plank 5 with a plurality of bolt element holes, and the top plank 3 with a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com