Film magazine monitoring system

A monitoring system and cassette technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as failure to detect abnormal mechanical stepping motors in time, large-area wafer damage, and wafer damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

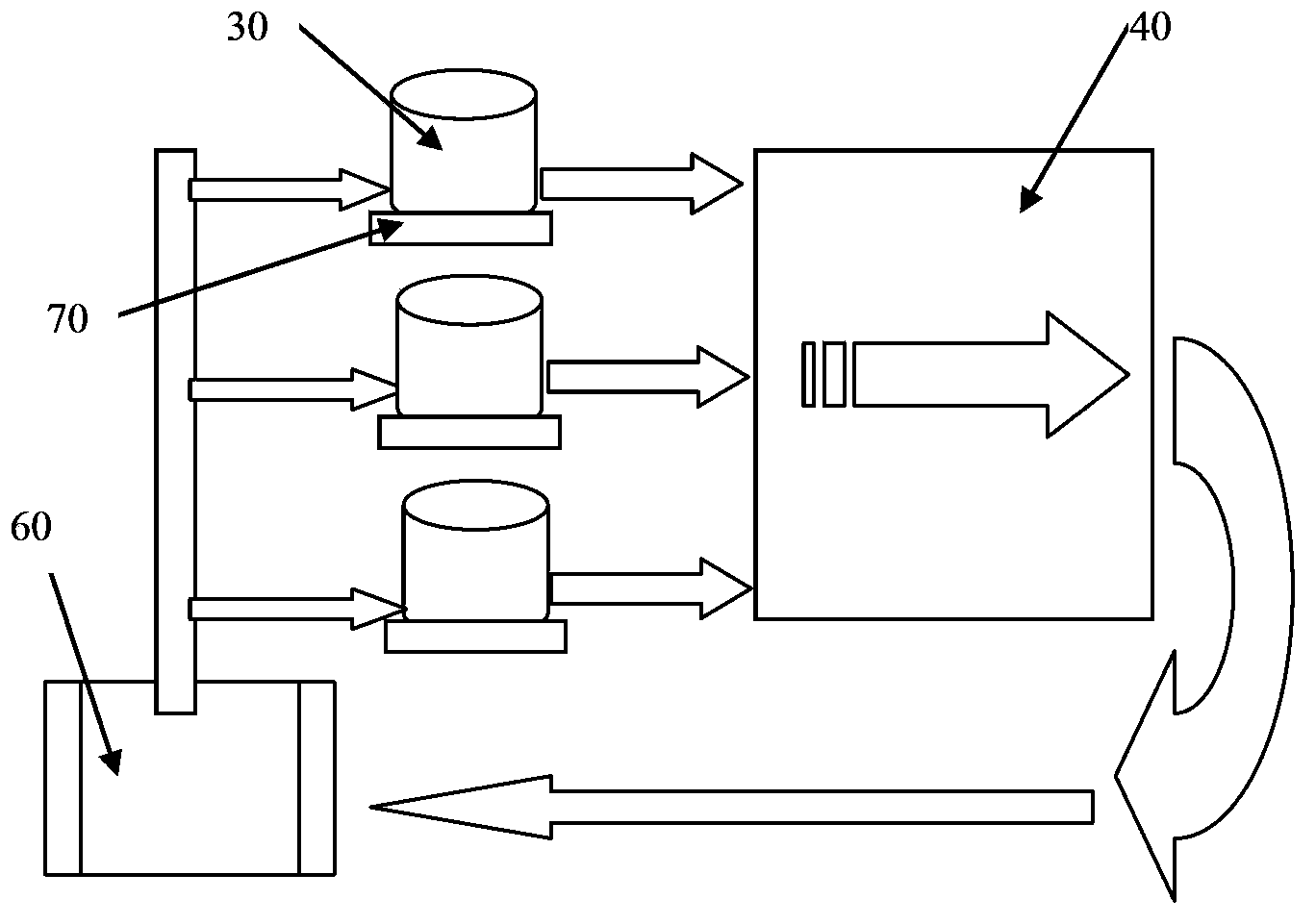

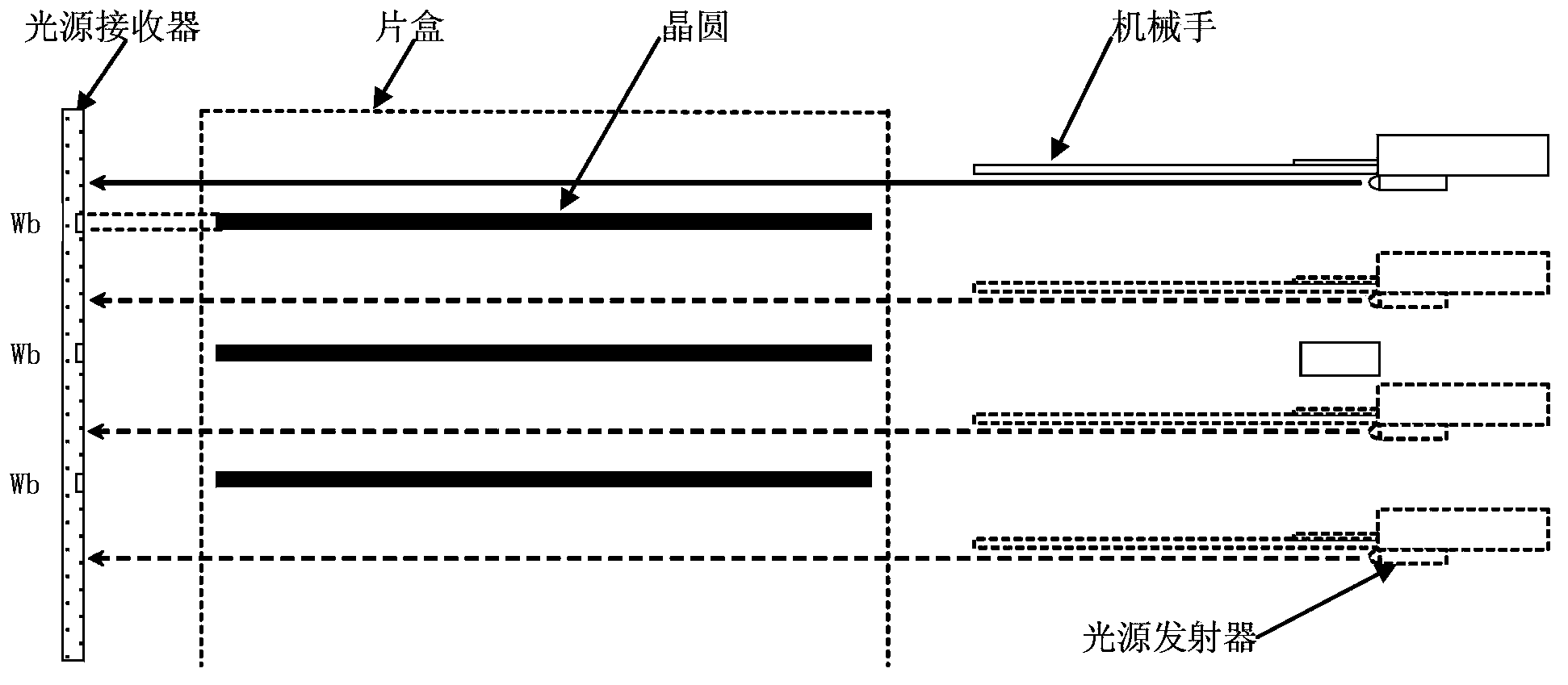

[0028] Cassette monitoring systems such as figure 2 , image 3 As shown, including loading platform, manipulator, light source transmitter, light source receiver, processor;

[0029] The loading platform is used to place the cassette;

[0030] The manipulator is located on one side of the loading platform, and is used to pick and place wafers in the cassettes placed on the loading platform;

[0031] The light source emitter is fixed on the manipulator and is used to emit light parallel to the plane of the manipulator to the other side of the loading platform;

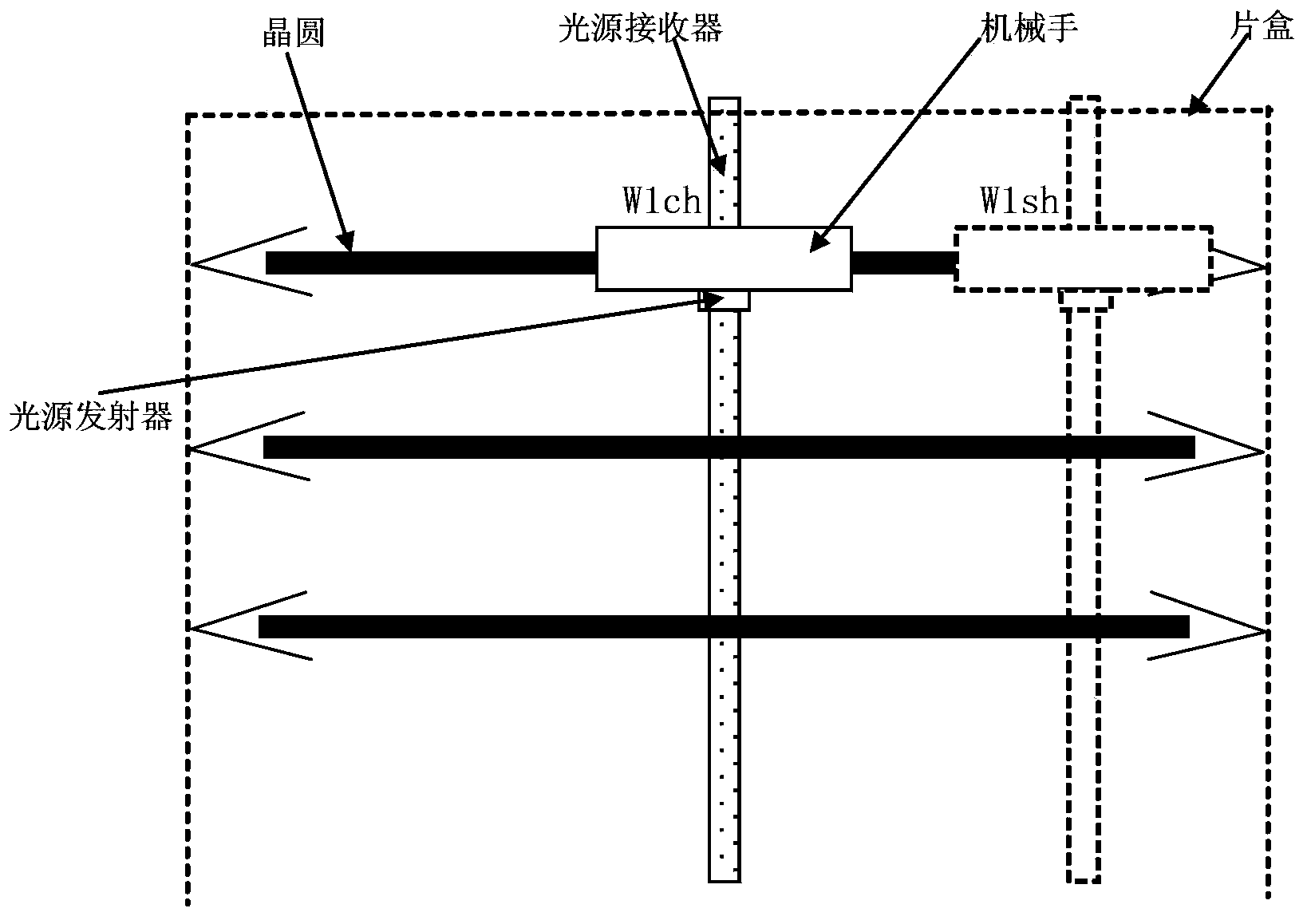

[0032] The light source receiver is arranged on the other side of the loading platform, and is used to receive the light emitted by the light source emitter, and output the light emitted by the light source emitter. The height Wch of the central point of the wafer blocking area, and the height Wsh of the side points of the wafer blocking area;

[0033] The processor is configured to output the thickness Wt of the b...

Embodiment 2

[0040] The light source emitter emits light parallel to the plane of the manipulator when the manipulator moves between the wafers in the cassette;

[0041] The light source receiver, when receiving light, also outputs a light arrival signal to the processor;

[0042] The processor, if the light arrival signal is not received within a set time after the movement of the manipulator to the wafers in the cassette, the processor outputs a manipulator failure alarm signal;

[0043] Such as Figure 6 As shown, when the manipulator moves between the wafers in the cassette, the light source emitter emits light parallel to the plane of the manipulator. If the manipulator is normal, the light parallel to the plane of the manipulator is also parallel to the wafers in the cassette On the upper and lower surfaces, the light emitted by the light source transmitter will pass through the gap between the manipulator and the wafer surface, and be received by the light source receiver on the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com