Self-Calibrating Harmonic Current Transformer Based on Gap Core Coil

An iron core coil and harmonic current technology, applied in voltage/current isolation, instrumentation, measurement of electrical variables, etc., can solve problems such as inability to overcome the measurement frequency band and affect the accuracy of current detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

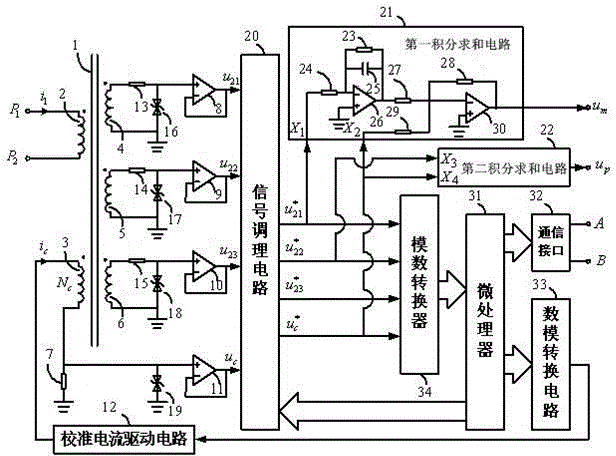

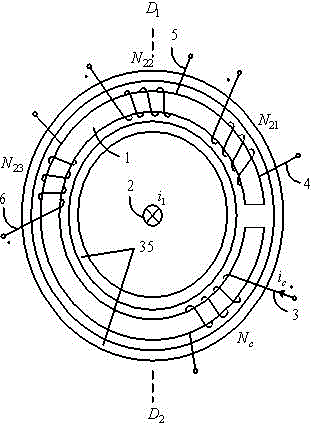

[0050] Example: as figure 1 , figure 2 , image 3 As shown, the present invention is a self-calibrating harmonic current transformer based on a gapped iron core coil.

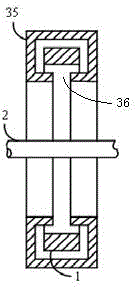

[0051] Iron core with gap (ring) 1, primary coil 2, secondary coil 4 for measurement, secondary coil 5 for protection, secondary coil 6 for monitoring, calibration coil 3 and annular shielding box 35 with slotted inner ring constitute the primary current Sensor; the secondary coil 4 for measurement, the secondary coil 5 for protection, the secondary coil 6 for monitoring and the calibration coil 3 are uniformly wound on the annular iron core 1 with a gap to form an annular core coil; the sampling resistor 7 is used A purely resistive precision resistor with a resistance value of 1KΩ and a temperature drift rate lower than 5ppm / °C; the digital-analog signal amplifier circuit 12 adopts a single-tube common-emitter amplifier circuit; Groove 36; communication interface 32 is RS485 communication interface.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com