Unit type automatic punching robot flexible connection mode

A robot and unit technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of unable to meet the requirements of maximizing the interests of enterprises, unable to meet the requirements of production, changing market demands, etc., to maximize the interests of enterprises , Improve equipment utilization and reduce the effect of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

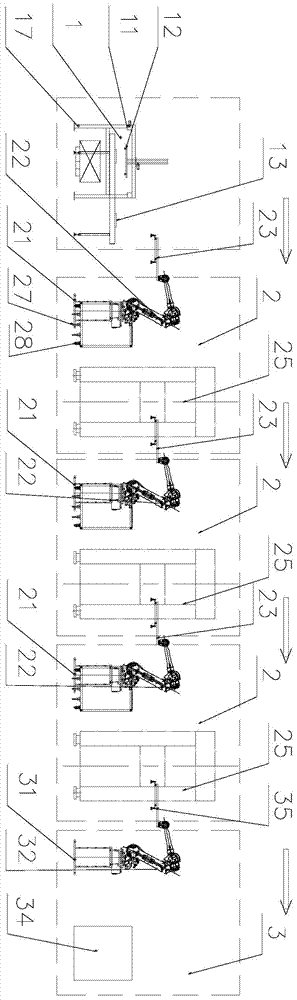

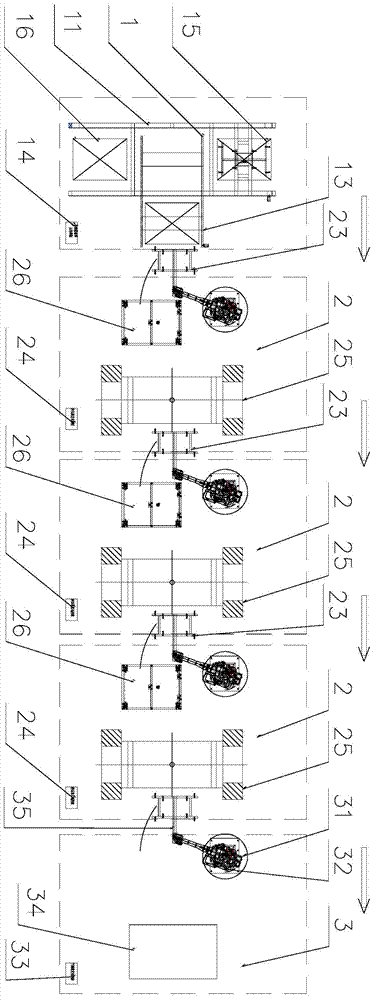

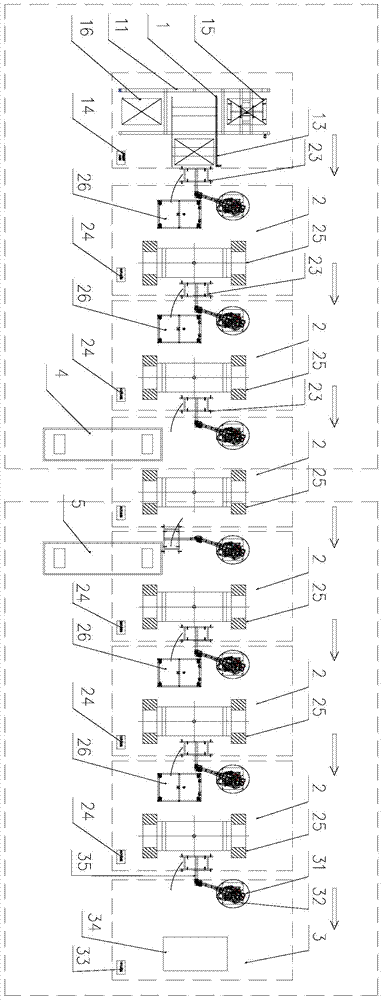

[0021] Example: see figure 1 , figure 2 , image 3 As shown, a flexible connection method for a unitary automatic stamping robot provided by the present invention includes a destacking clapper unit 1 located at the front end of the stamping unit 2, and a blanking unit 3 located at the end of the line body. The above-mentioned units are respectively It is controlled by an independent unit control box, and then connected to the main control box through the connection system. The unit control box includes the unstacking clapper unit control box 14, the stamping unit control box 24, and the unloading unit control box 33. According to production needs, It can not only realize one-flow automatic production but also realize relatively independent combined multi-variety automatic production. The destacking clapper unit 1 is installed before the stamping unit 2 through the frame 17, the servo traverse mechanism 11 is installed on the frame 17, and the servo lifting and grabbing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com