Equipment for handling workpieces

A technology for workpieces and equipment, applied in the field of processing workpieces, capable of solving problems such as contamination of workpiece cooling lubricants and debris, damage to technical functions, failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

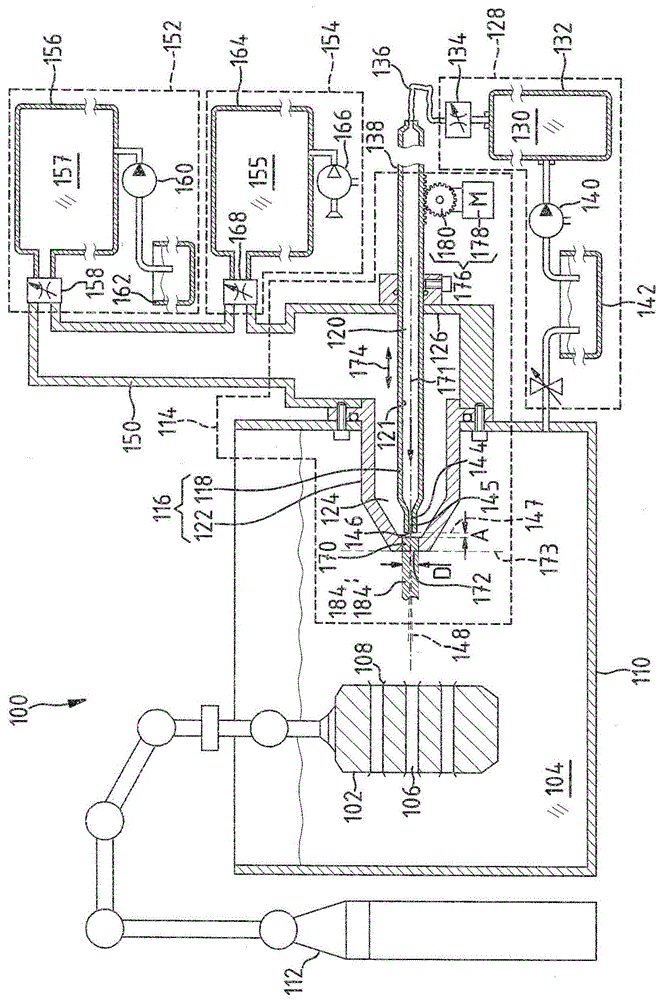

[0034] figure 1 A cleaning device 100 is shown for rinsing workpieces 102 in a liquid bath 104 . The cleaning device 100 is a processing device for a workpiece 102 in the form of an aluminum cylinder head in which a plurality of boreholes 106 are formed. In order to insert the drill hole, the workpiece 102 is machined in a machining center chip-cutting. In the cleaning device 100 the workpiece 102 is not only cleaned of dirt in the form of cooling lubricants and debris. The cleaning device 100 also enables the deburring of workpieces, that is to say the removal of burrs 108 on the workpiece 102 which originate from chip machining in the machining center.

[0035] The liquid tank 104 is located in the liquid container 110 . A handling robot 112 is present in the cleaning device 100 . The workpiece 102 can be accommodated in the cleaning device by the handling robot 112 and manipulated with three translational and three rotational degrees of freedom in the liquid tank 104 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com