Long-break-distance contact structure capable of breaking rapidly

A fast, contact technology used in circuit breaker contacts, protective switch operation/release mechanisms, circuit breaker components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

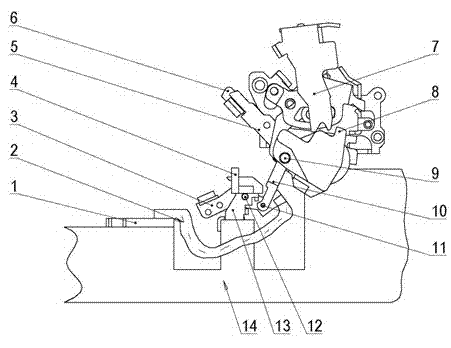

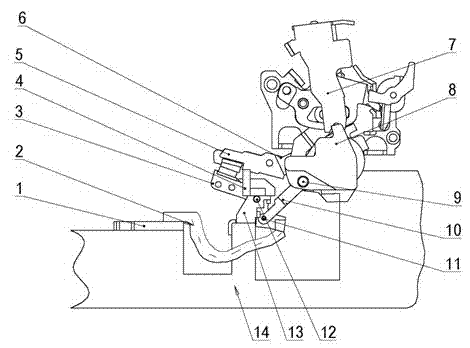

[0016] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

[0017] As shown in the figure, a large-distance contact structure that can be broken quickly includes a base 14, an operating mechanism 7, a moving contact 6, a static contact 3, and a rotating part 8. The moving contact 6 is installed on a rotating On the part 8, the operating mechanism 7 cooperates with the rotating part 8 to drive the movable contact 6 to rotate at a certain angle. The base 14 is provided with a wiring board 1 and a soft connection 2. Welded together with the wiring board 1, the base 14 is equipped with a support 13, the static contact 3 is hinged on the support 13 through the shaft 12, the support is fixed on the base by screws, the static contact The head 3 can rotate at a certain angle and is installed on the support member 13. The rotating member 8 is connected with the static contact 3 through the transmission member 10, and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com