Mutual feedback device for performance testing of roller-shaped linear induction traction motors for rail transit

A linear induction motor and linear induction technology, applied in the field of electric traction transmission, can solve the problems that cannot meet the requirements and testing of linear induction traction motors, and achieve the effect of energy saving and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

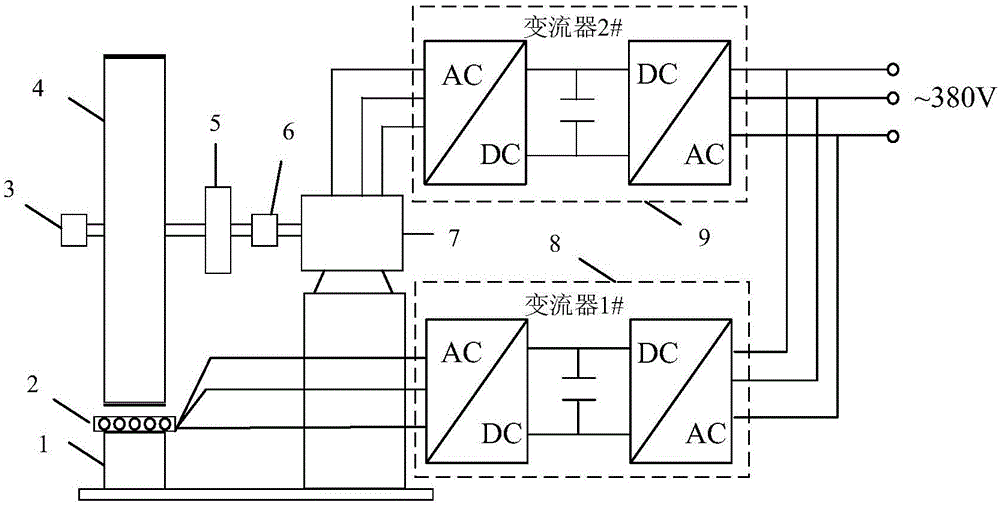

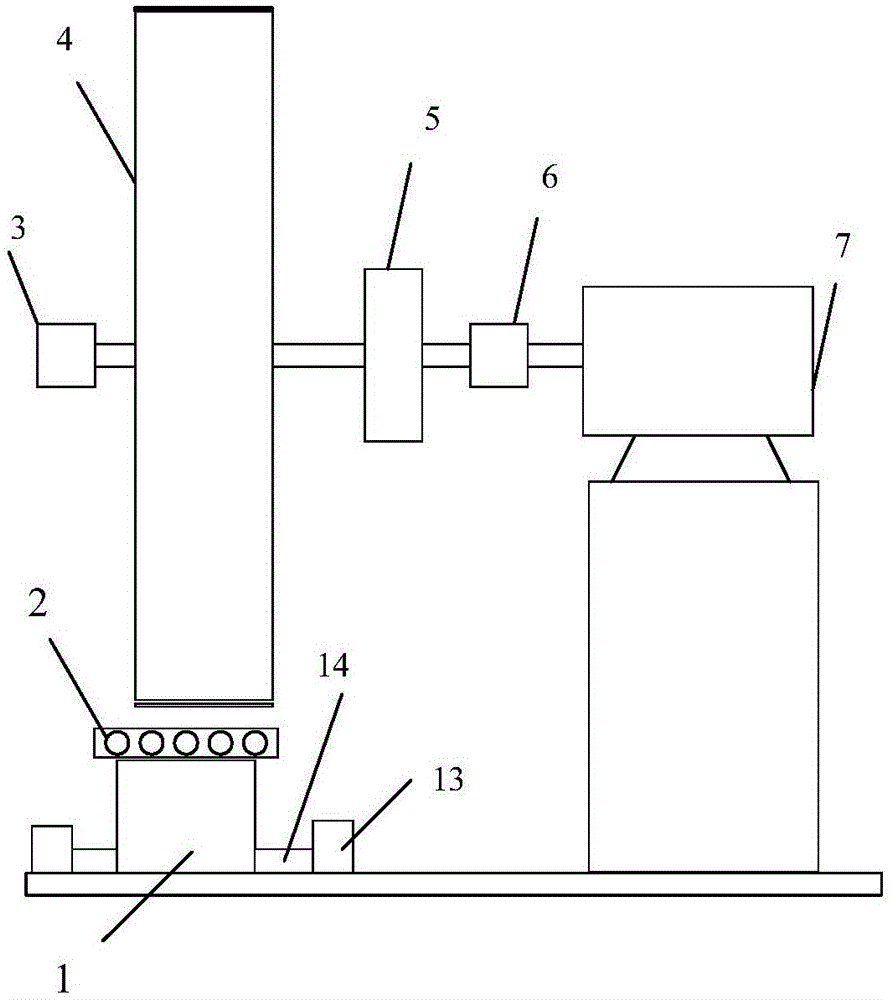

[0029] figure 1 It is a schematic diagram of the structure of the mutual-feedback device for the performance test of the drum-shaped linear induction traction motor. The device consists of a primary base 1, an arc-shaped linear induction motor primary 2, a rotary encoder 3, a drum-shaped secondary 4, a flywheel coupling 5, a torque meter 6, a rotary induction motor 7, the first # converter 8, the second 2# Converter 9 is composed. The arc-shaped linear induction motor primary 2 is fixed on the primary base 1, and the arc of the arc-shaped linear induction motor primary 2 matches the drum-shaped secondary 4, that is, the center of the circle coincides; the arc-shaped linear induction motor primary 2 and the drum-shaped secondary 4 There is an air gap between them, and the width of the air gap is set to the rated working value of the line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com