Method for quickly measuring content of calcium carbonate in paper through headspace gas chromatography

A headspace gas chromatography and rapid determination technology, applied in the field of papermaking, can solve the problems of low accuracy, unreported calcium carbonate fillers, and many influencing factors, and achieves high accuracy, fast measurement speed, and improved normal operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

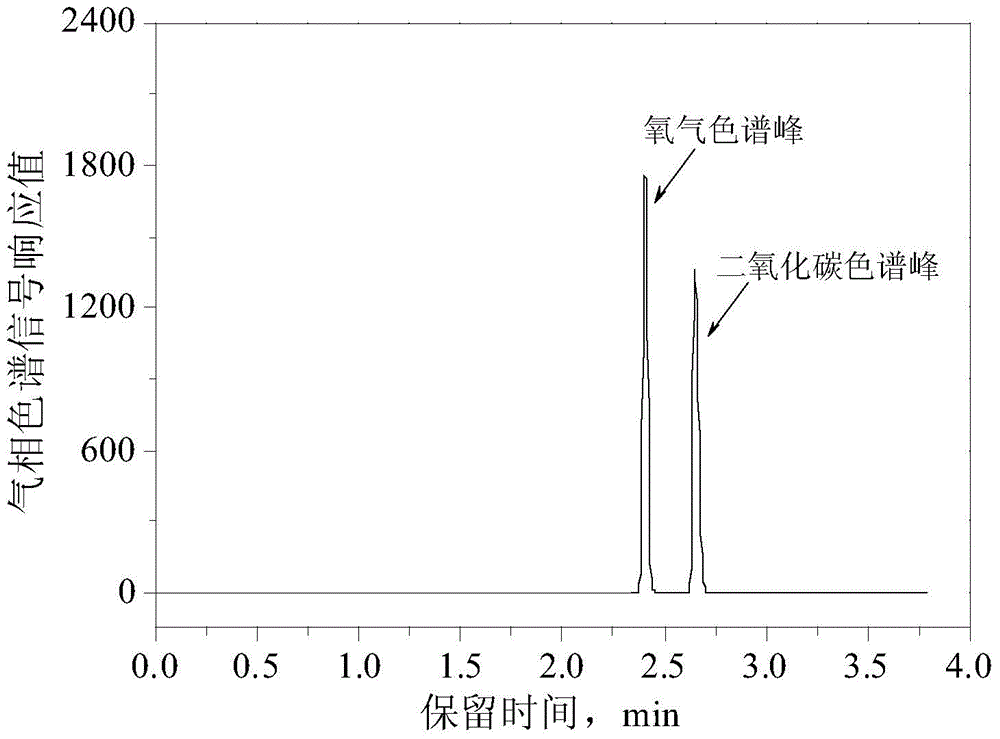

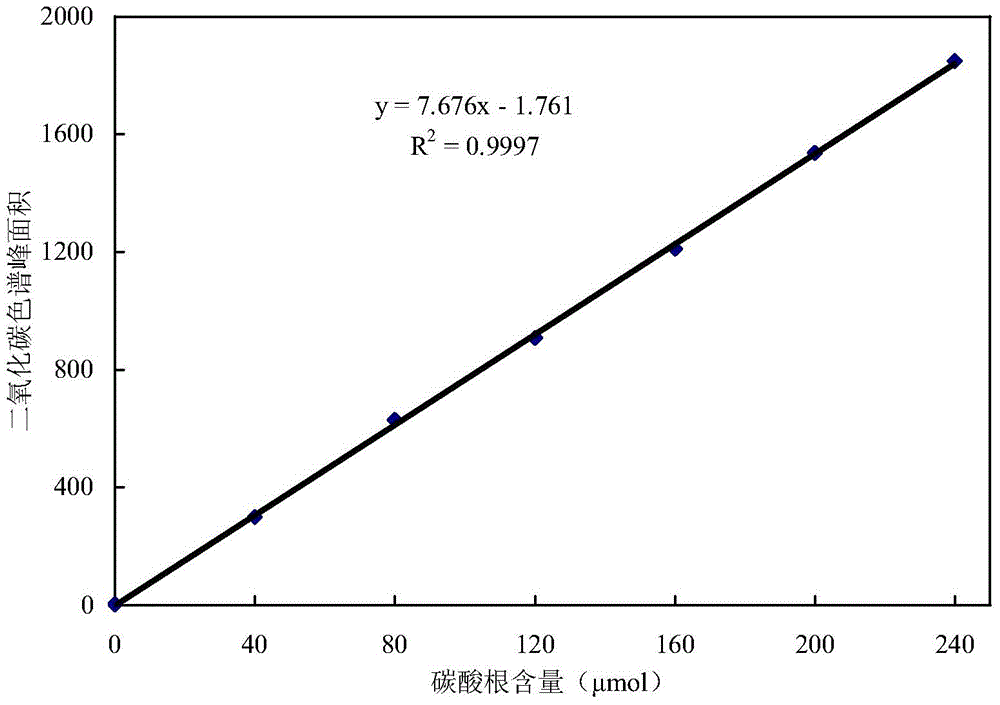

Method used

Image

Examples

Embodiment 1

[0028] 1) Weigh a paper sample with an absolute dry mass of 1.9946 grams (the paper sample is taken from a commercially available 70g / m 2 Ordinary copy paper), shredded into small pieces, placed in a high-speed disperser with a volume of 500mL, and added 250mL of sodium hydroxide solution with pH=9, dispersed at high speed for 3 minutes, and prepared into a pulp with a concentration of about 0.8% by mass suspension.

[0029] 2) Remove the pulp suspension in the high-speed disperser, and use an electric or magnetic stirrer at a certain speed to disperse the pulp fibers and filler particles evenly in the pulp suspension. Under continuous stirring, pipette 10 mL of the pulp suspension into a 20 mL headspace bottle, and seal the headspace bottle with a polytetrafluoroethylene / butyl rubber gasket and an aluminum cap. Then add 2 mL of sulfuric acid solution with a concentration of 2 mol / L with a syringe. Finally, the headspace vial loaded with the paper sample was sonicated ...

Embodiment 2

[0039]1) Weigh a paper sample with an absolute dry mass of 1.4909 grams (the paper sample is taken from Fujian Nanzhi Paper Co., Ltd.), tear it into small pieces, place it in a high-speed disperser with a volume of 500mL, and add pH =10 sodium hydroxide solution 250mL, dispersed at high speed for 3 minutes, and prepared into a pulp suspension with a concentration of about 0.6% by mass.

[0040] 2) Remove the pulp suspension in the high-speed disperser, and use an electric or magnetic stirrer at a certain speed to disperse the pulp fibers and filler particles evenly in the pulp suspension. Under continuous stirring, pipette 10 mL of the pulp suspension into a 20 mL headspace bottle, and seal the headspace bottle with a polytetrafluoroethylene / butyl rubber gasket and an aluminum cap. Then add 2 mL of sulfuric acid solution with a concentration of 2 mol / L with a syringe. Finally, the headspace vial loaded with the paper sample was sonicated for 6 minutes.

[0041] 3) Put the he...

Embodiment 3

[0050] 1) Weigh a paper sample with an absolute dry weight of 1.8013 grams (the paper sample is taken from Fujian Jinjiang Youlanfa Paper Co., Ltd.), tear it into small pieces, place it in a 500mL high-speed disperser, and Add 250mL of sodium hydroxide solution with pH=9, disperse at high speed for 3 minutes, and prepare a pulp suspension with a concentration of about 0.7% by mass.

[0051] 2) Remove the pulp suspension in the high-speed disperser, and use an electric or magnetic stirrer at a certain speed to disperse the pulp fibers and filler particles evenly in the pulp suspension. Under continuous stirring, pipette 10 mL of the pulp suspension into a 20 mL headspace bottle, and seal the headspace bottle with a polytetrafluoroethylene / butyl rubber gasket and an aluminum cap. Then add 2 mL of sulfuric acid solution with a concentration of 2 mol / L with a syringe. Finally, the headspace vial loaded with the paper sample was sonicated for 8 minutes.

[0052] 3) Put the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com