Construction method for using parallel double-mast half-turning method to hoist large box type derrick

A construction method and double-mast technology, applied in the direction of drilling equipment, earthwork drilling, support devices, etc., can solve the problems of high cost of hoisting equipment, large amount of equipment usage, and long construction period, so as to improve efficiency, reduce consumption, reduce input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

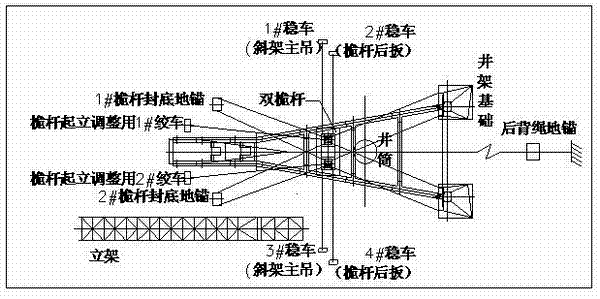

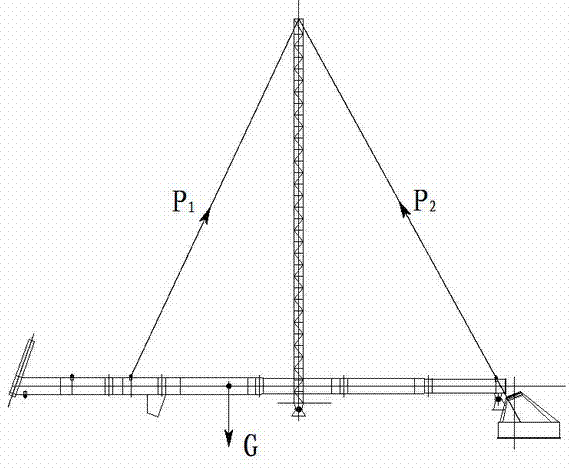

[0055] As shown in the figure, the construction method of lifting a large box-type derrick by the side-by-side double-mast semi-turning method, the process steps are: Construction preparation, Drilling winch fixed, pair of masts, rigging set, the mast rises, hoisting of the main inclined frame, mast removed, stand hoisting, clean up the construction site, Ancillary facilities installation.

[0056] The hoisting steps of the main inclined frame include:

[0057] Raising the head of the main inclined frame — Slowly raise the head of the main inclined frame so that the main inclined frame is completely detached from the assembled steel frame and then stop hoisting, seal the sinking winch, stop for 1 hour for safety inspection, and then lift after confirming that it is safe;

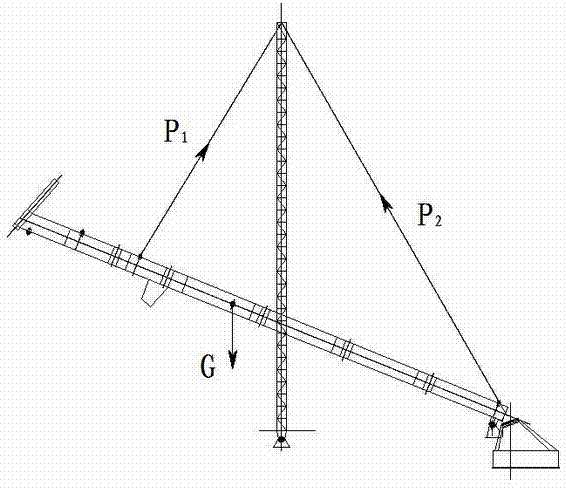

[0058] Start the main crane sinking winch of the inclined frame, and stop lifting when the main inclined frame is hoisted to an angle of 40-45° with the ground;

[0059] Pull the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com