A heating floor system

A floor and floor board technology, applied in electric heating systems, heating systems, household heating, etc., can solve the problems of time-consuming and expensive, poor quality of heating floors, and inability to control heating temperature well, and achieve heating effect. Good, good sealing, high electrothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

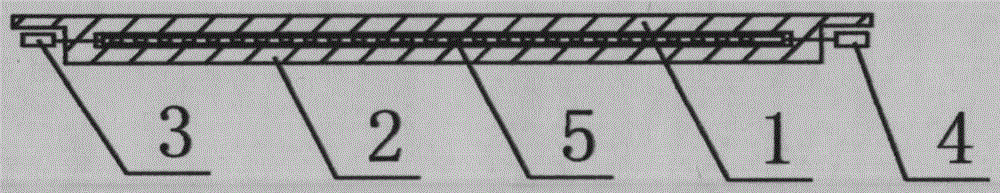

[0021] In the figure, 1. Panel; 2. Substrate; 3. Male plug; 4. Female socket; 5. Base film; 6. Electrode; 7. Temperature control element; 8. Raised strip; 9. Groove; ; 11. Power bus; 12. T-shaped head.

[0022] Such as Figures 1 to 7 As shown, a plurality of floor boards are assembled to form a floor strip, and the power bus 11 is connected to the floor board through a T-shaped head 12. The floor board includes a panel 1, a substrate 2, an electric heating film, a male plug 3 and a female socket 4, and the electric heating film is sealed on the In the cavity between the panel 1 and the base plate 2, the material of the panel 1 and the base plate 2 is wood or porcelain, and the electrothermal film includes a base film 5, an electrode 6 and a wire, and the base film 5 is provided with two electrodes 6, and the electrode 6 and the wire connection, the electrothermal film is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com