Inclined hoisting method of single hoisting point of steam drum

A hoisting method and steam drum technology, which are applied in the directions of transportation and packaging, load hanging components, supporting structures, etc., can solve the problems that the truck crane cannot complete the hoisting, the height of the truck crane is limited, and the requirements for hoisting equipment are high, so as to shorten the hoisting period, The effect of reducing labor input and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

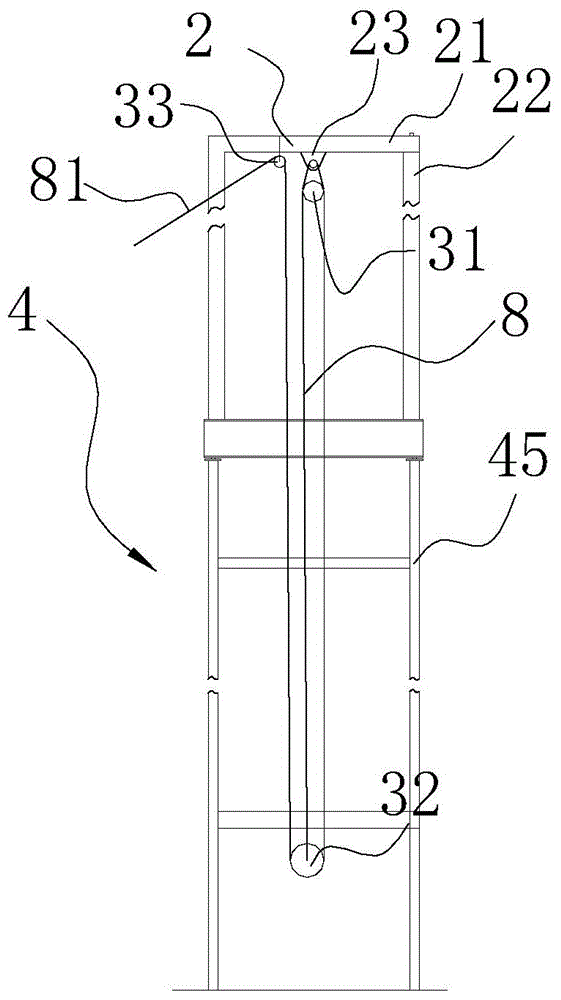

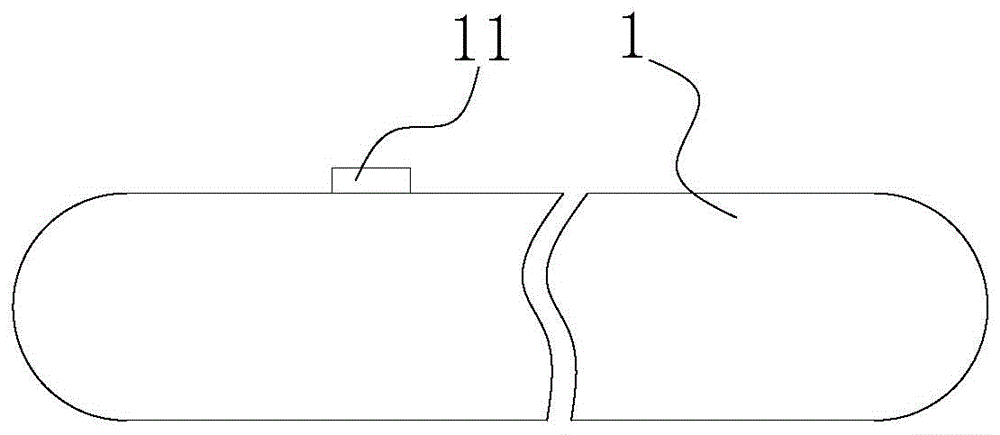

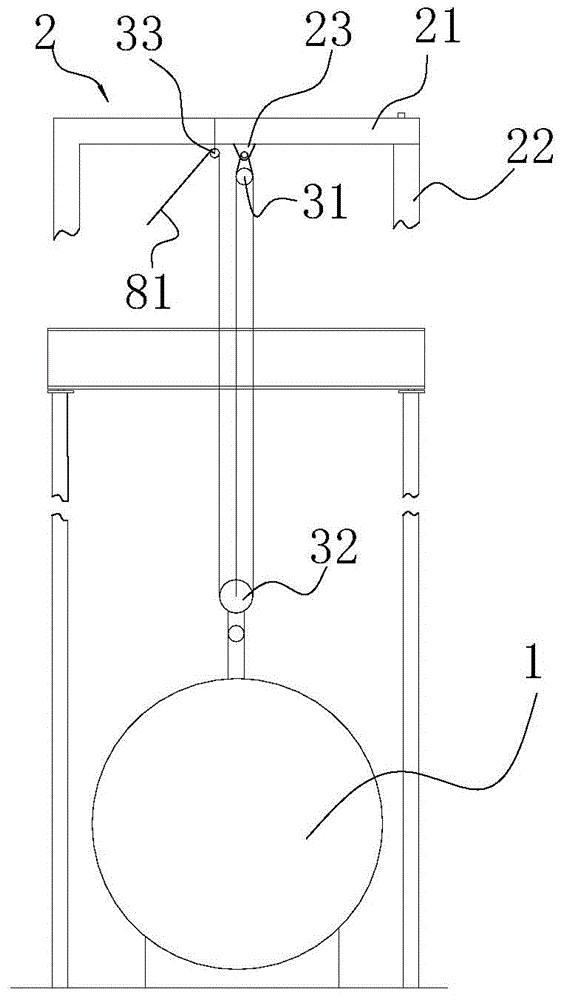

[0062] Such as Figure 1 to Figure 7The steam drum hoisting device comprises a temporary hanging beam 2, a winch 5, a rope 8 and a pulley block; the temporary hanging beam 2 includes a crossbeam 21, a support column 22; the pulley block includes a first fixed pulley 31, a second fixed pulley 33 and a movable pulley 32; the upper end of the supporting column 22 is provided with a crossbeam 21, and the crossbeam 21 is provided with a lifting lug 21, and the first fixed pulley 31 is installed on the lifting lug 21 through a snap ring; the second fixed pulley 33 is installed on the crossbeam 21 , the side that the first fixed pulley 31 has is parallel to the side that the second fixed pulley 33 has; one end of the rope 8 is fixed on the center of the movable pulley 32, and the other end is wound around the first fixed pulley 31, the movable pulley 32, The second fixed pulley 33 is connected with the winch 5 .

[0063] Use the above-mentioned steam drum hoisting device to hoist th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com