Protein filament extruding device

An extrusion device and protein technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of not meeting process requirements, time-consuming and laborious, uneven water content of protein silk, etc., and achieve the effect of improving production efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

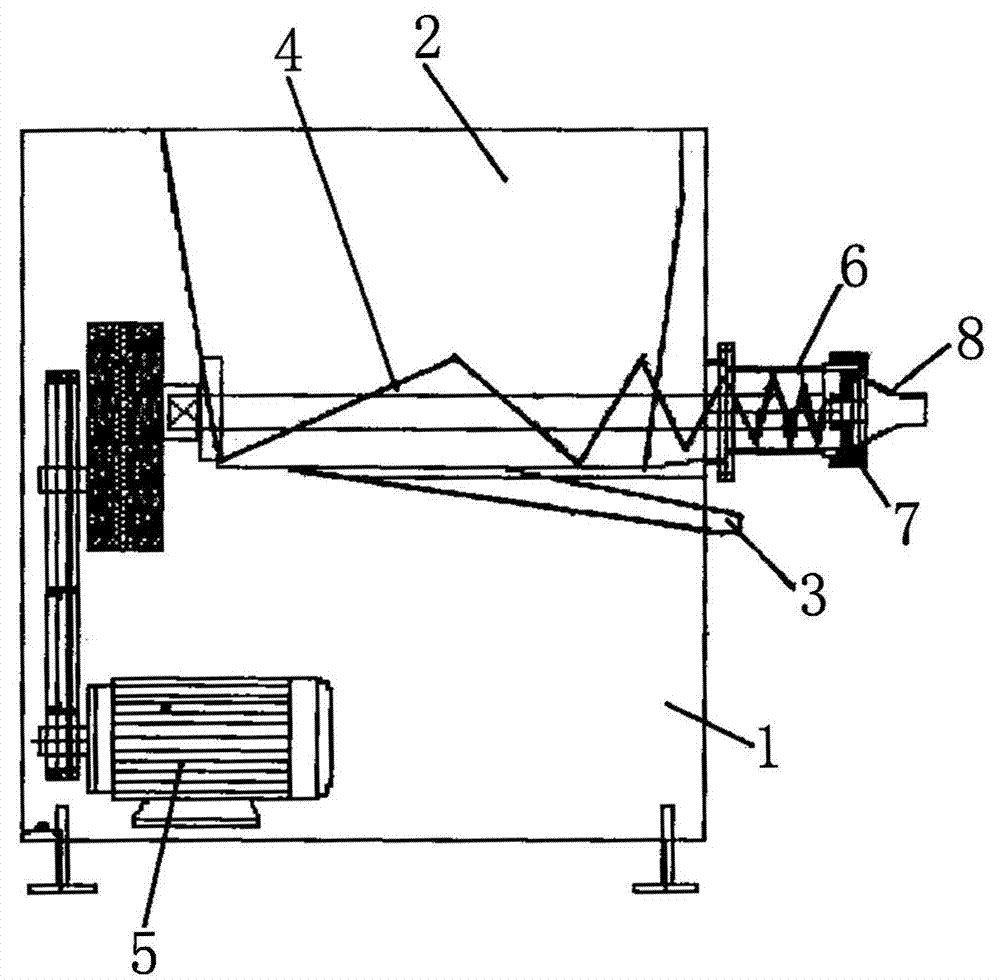

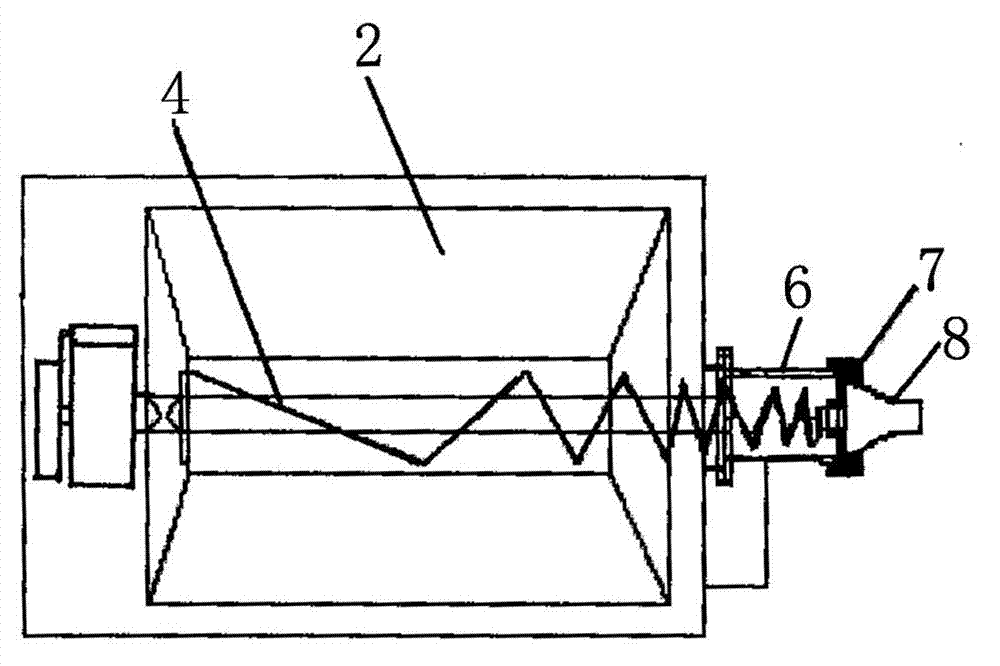

[0010] Such as figure 1 , 2 As shown, the present invention is provided with a V-shaped hopper 2 above the interior of the casing 1, and an inclined water outlet 3 is provided at the bottom of the V-shaped hopper 2. One end of the water outlet 3 stretches out from the outer wall of the casing 1, and the twisted cage 4 Located at the bottom of the V-shaped hopper 2, the pulley at one end of the twisted cage 4 is connected to the motor 5 at the bottom of the box body 1 through a belt, and the other end of the twisted cage 4 is inserted into the extrusion jacket 6 outside the box body 1. An extrusion mouth 8 is provided on the extrusion jacket 6 via a locking nut 7 . Through the above settings, the fully soaked protein filaments are put into the V-shaped hopper 2 of the present invention, and the motor 5 drives the twisted cage 4 to continuously rotate, so that the protein filaments in the V-shaped hopper 2 advance, and the protein filaments are extruded by the rotation of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com