A remote control automatic maintenance device and maintenance method for a target in a hot chamber environment

An automatic maintenance and environmental technology, applied in the direction of manipulators, manufacturing tools, etc., can solve problems such as low maintenance efficiency, inability to approach equipment, and operator fatigue, to eliminate visual errors, improve efficiency and intelligence, and overcome inefficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

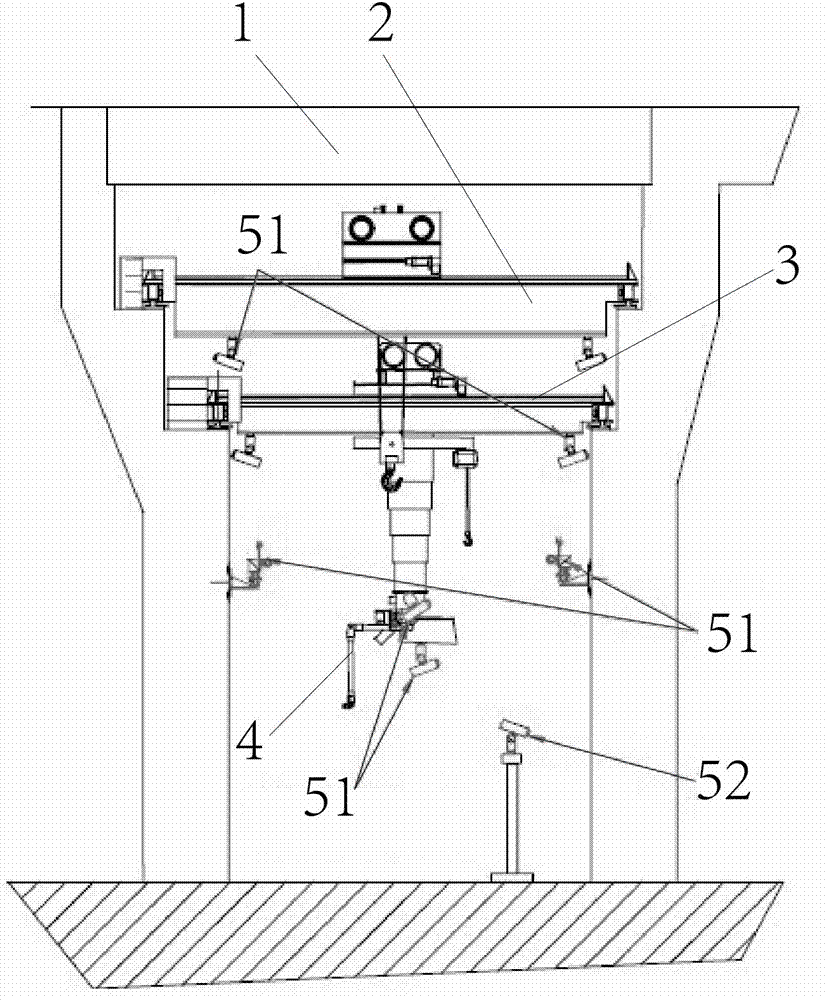

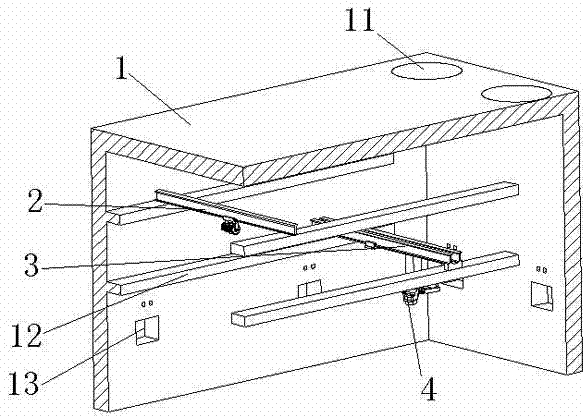

[0023] A target body remote control automatic maintenance device in a hot room environment, the overall structure of the target body remote control automatic maintenance device includes a closed hot cell 1, a crane 2, a crane 3, a power manipulator 4 and a stereo vision 5, the The airtight hot chamber 1 is provided with a cavity for installing the upper crane 2 and the lower crane 3, and an inlet cover 11 is installed on the top surface of the airtight hot chamber 1, and two inlet covers 11 are arranged; There are two convex grooves 12 with symmetrical upper and lower positions on both side walls and a symmetrical groove 13; the groove on the inner side wall of the airtight heat chamber 1 has at least one large groove and one small groove;

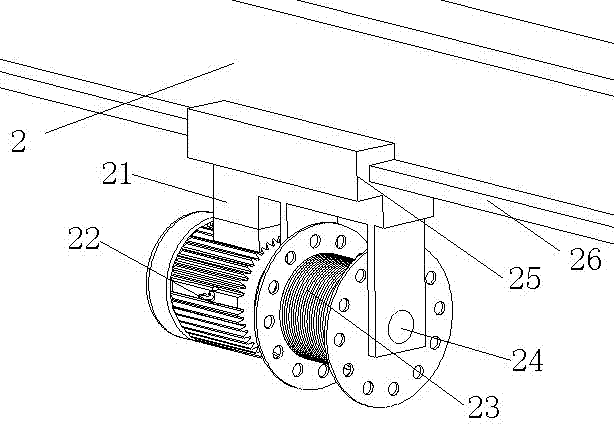

[0024] The above crown trolley 2 presses against the inner side walls of the airtight heat chamber 1 by pressing force, and is fixedly suspended above the upper convex groove 12 of the airtight heat chamber 1. The crown trolley 2 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com