Large outdoor power distribution room and its installation method

A power distribution room, outdoor technology, applied in the field of substations, can solve the problems of low efficiency, long assembly process, difficult installation of roof and box, etc., to achieve the effect of speeding up installation speed, simple installation, and reducing installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

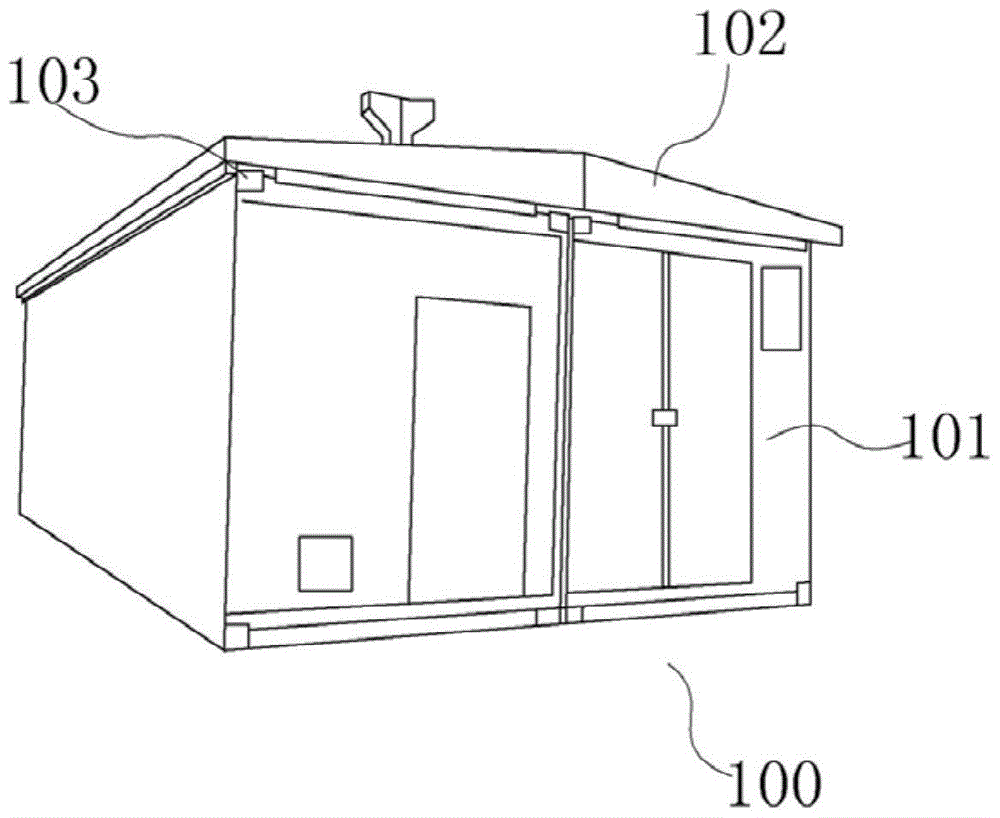

[0021] see figure 1 , which is a schematic structural diagram of the large outdoor power distribution room provided in this example. The large outdoor power distribution room 100 mainly includes two parts of a box body 101 and a roof 102 .

[0022] Wherein, the box body 101 is the main structure of a large-scale outdoor power distribution room (box-type substation and box-type switching station), and is used for installing necessary components of the outdoor power distribution room. In order to facilitate installation and modular arrangement, the box body 101 adopts a container box structure.

[0023] The roof 102 is used to seal the box body 101 from the upper part to form a large outdoor power distribution room, and its size and shape match with the box body 101 .

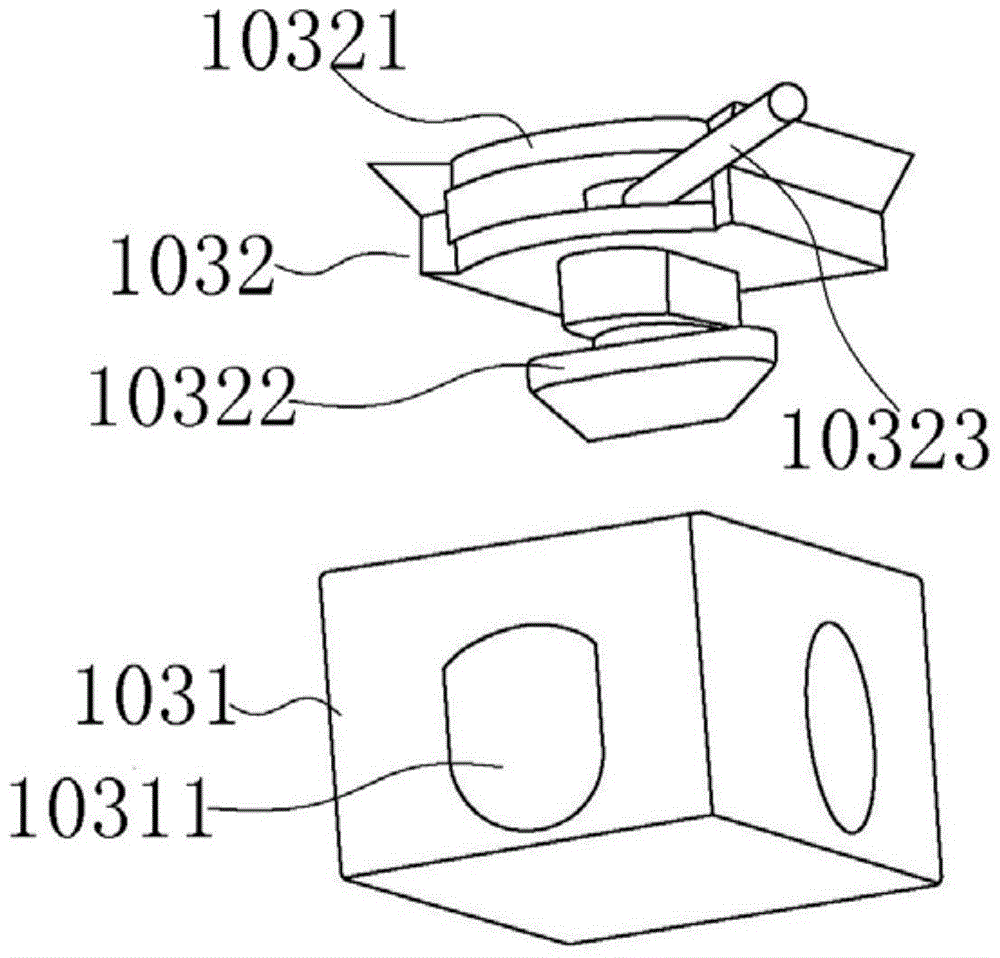

[0024] In order to quickly and accurately assemble the box body 101 and the roof 102 , a corner piece rotation lock device 103 is provided between them, and the roof 102 can be quickly locked on the box body 10...

example 2

[0037] The solution provided in this example is similar to that provided in Example 1, except that the corresponding installation relationship between the container corner fittings 1031 and corner fitting rotation locks 1032 in the corner fitting rotation lock device 103 and the box body 101 and the roof 102 is different. Among them, the corner piece rotation lock 1032 is fixedly placed at the four corners of the installation surface (that is, the surface connected to the roof) on the box body 101, and the container corner piece 1031 is fixedly embedded in the back of the roof and the box body. Part rotation lock 1032 position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com