Anti-winding flap type rudder guide rod transmission device

A technology of guide rod transmission and transmission device, which is applied in rudder steering and other directions, can solve the problems of reducing the service life of the transmission device, consuming the energy of the steering gear, increasing the friction force of the guide rod device, etc., and achieves prolonging the service life, simple structure, The effect of easy installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

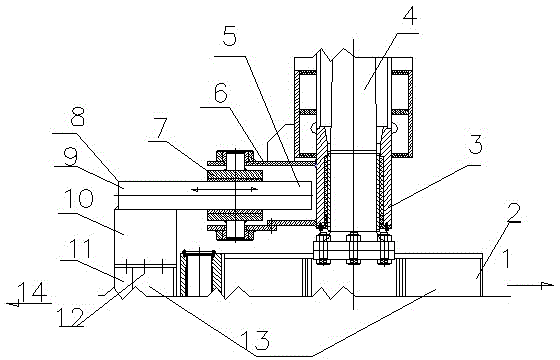

[0011] Below in conjunction with accompanying drawing, the present invention will be further described;

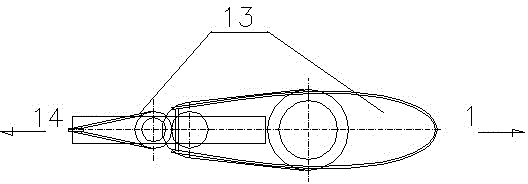

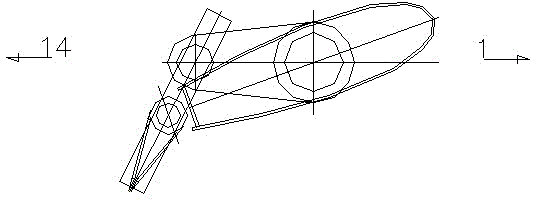

[0012] Anti-tangle flap rudder guide rod drive, incl. Guide rod 9, guide sleeve 7, fixing device 6, main rudder 2, It is characterized by: The fixed end 8 of the guide rod on the transmission device is designed in the direction of the stern 14 of the rudder blade 13, and the sliding end of the guide rod is arranged in the direction of the bow 1 of the rudder blade 13.

[0013] The transmission device is that the rudder stock protection cover 3 is arranged on the rudder stock 4, and the rudder stock protection cover 3 is provided with a fixing device 6 on one side of the stern 14 direction; between the fixing device 6 and the guide rod 9 A guide sleeve 7 with a pin positioned on the fixing device 6 is provided; the guide rod 9 is welded on the bracket 10; the bracket is fixed on the auxiliary rudder 11 by bolts 12

[0014] During specific implementation, as shown in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com