Long shafting arranging and installing method of platform work ship

A technology of shafting and captain, which is applied in the field of shafting arrangement of captains working on platforms, can solve the problems of easy deformation of long shafting, and achieve the effect of solving easy deformation, improving accuracy, and reliable and easy arrangement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

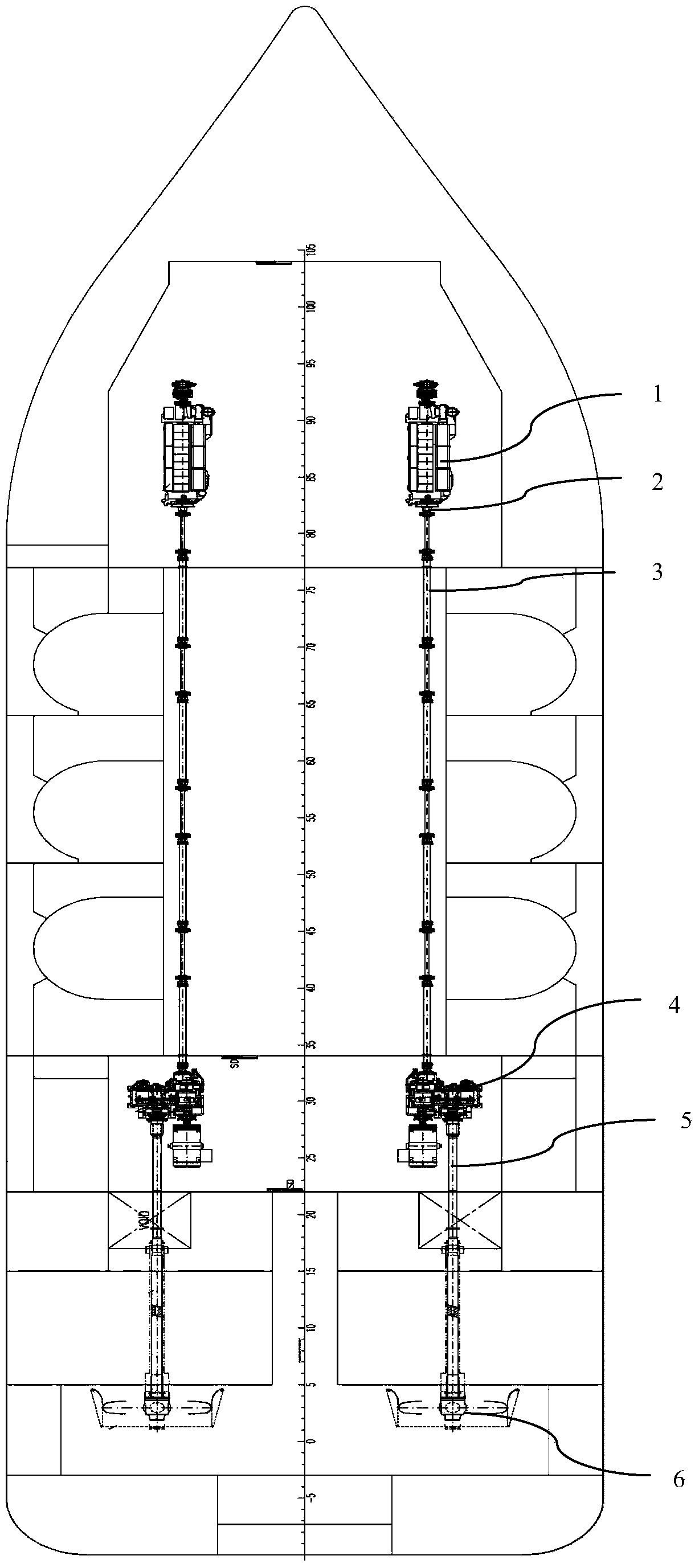

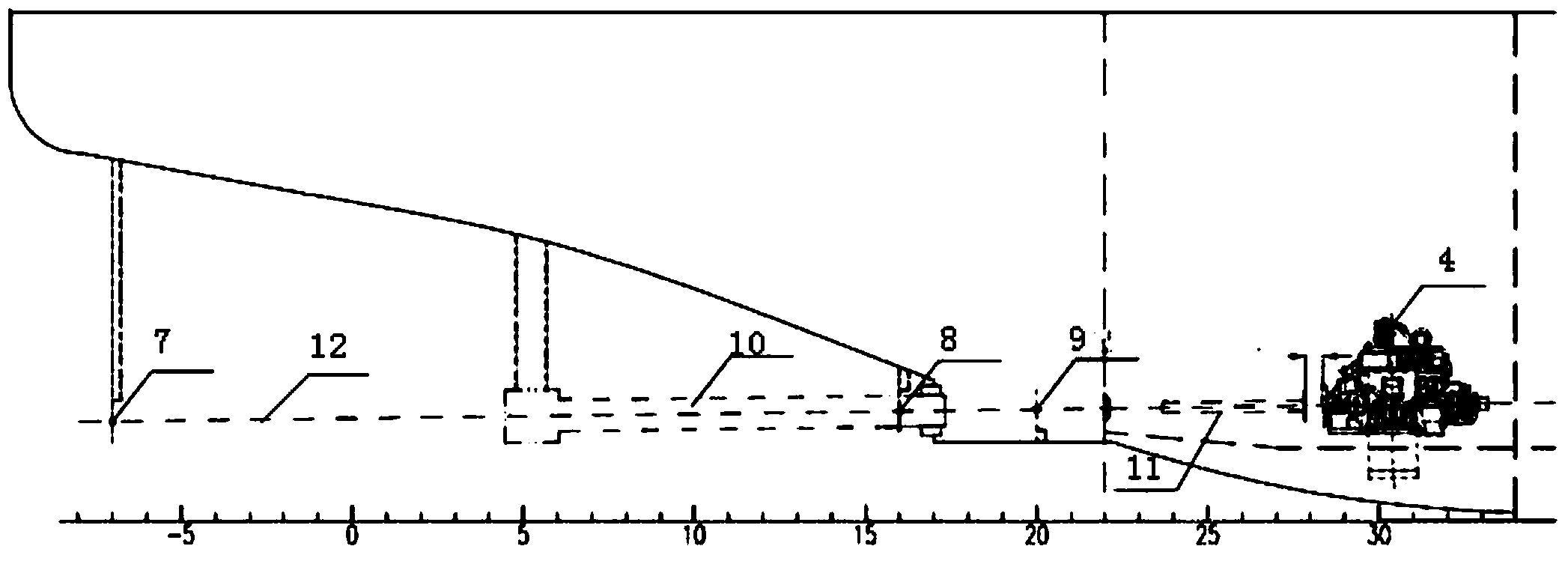

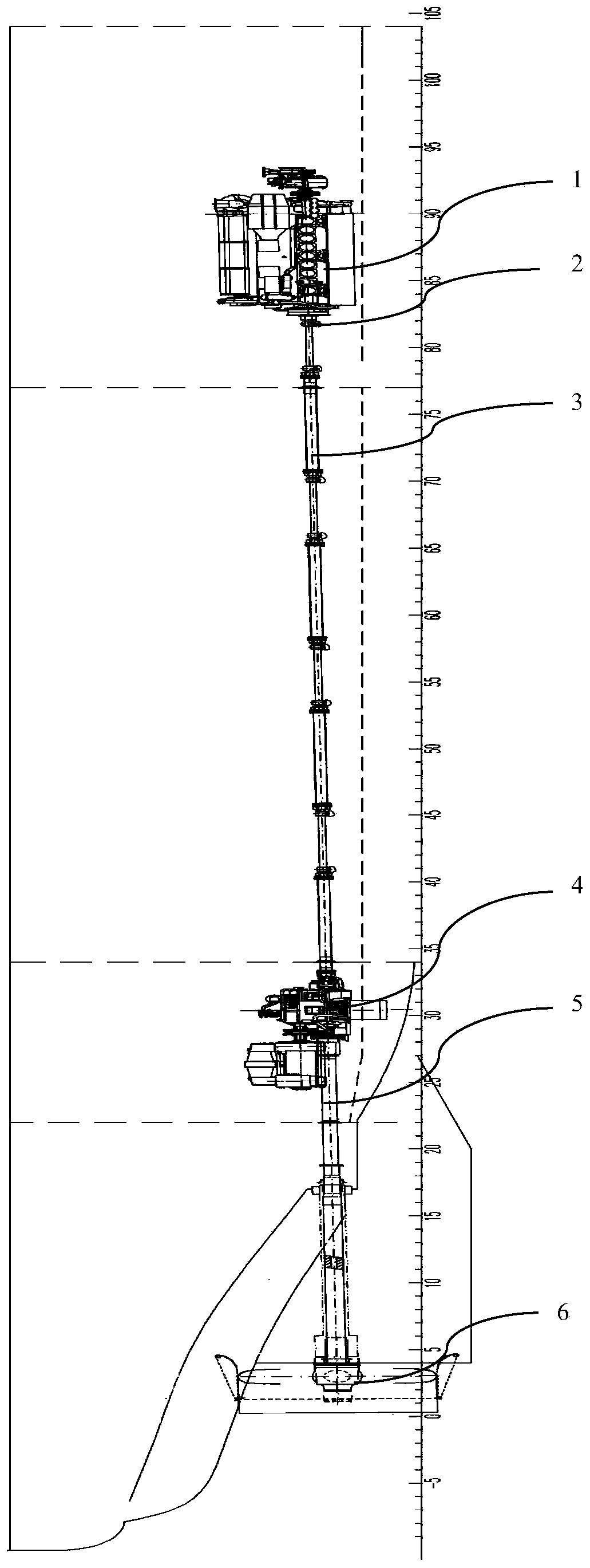

[0029] Such as figure 1 As shown, each propulsion system is mainly composed of the main engine 1 through the elastic coupling 2 → high-speed transmission shaft 3 → reduction gearbox 4 → stern shaft 5 → variable pitch propeller 6; the free end of the main engine 1 PTO with high elasticity → integral type Fire gear box → fire pump set. The high-speed transmission shaft 3 is composed of a solid shaft and a hollow shaft (without bearing support); the stern shaft 5 has no intermediate bearing support. The stern shaft 5 and the high-speed transmission shaft 3 are two axes parallel to each other.

[0030] Axis centering can be done by lighting method, wire drawing method, or a combination of the two. The purpose of lighting is to:

[0031] 1) Take the theoretical axis as the reference, combine the pull wires, review the center and longitudinal posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com