Swing material-hooking device

A hooking and swinging cylinder technology, applied in the field of profile positioning devices, can solve problems such as inability to accurately reach the clamping position, inability to complete the profile clamping function, and non-fixation, so as to achieve stable and smooth feeding process, convenient adjustment and control, and positioning high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

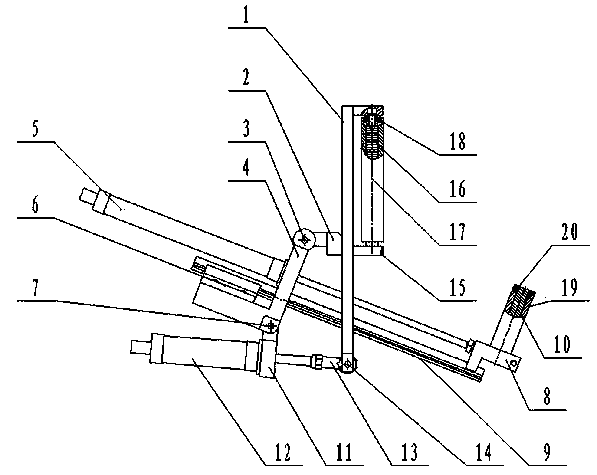

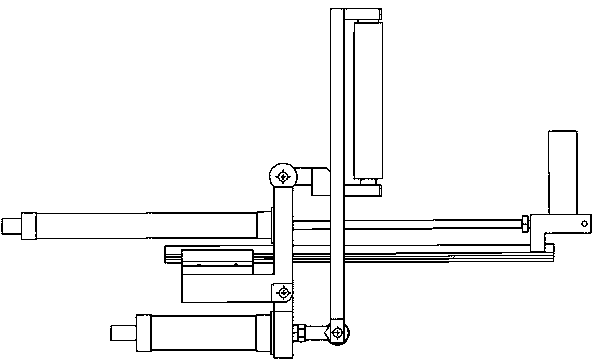

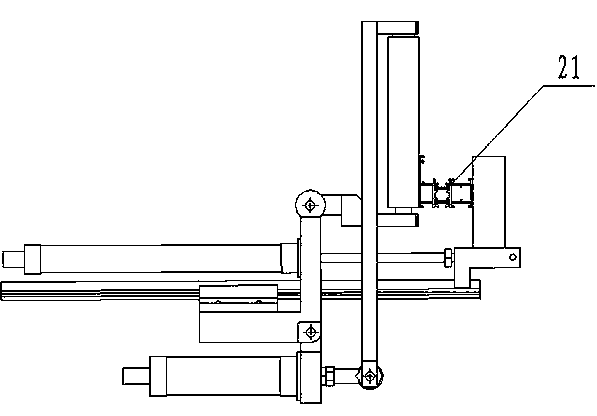

[0019] The present invention will be further described below through non-limiting embodiments and in conjunction with the accompanying drawings.

[0020] Figure 1 to Figure 4 It is a schematic diagram of a specific embodiment of the present invention, including a frame 23 and a beam 25 fixed on the frame 23, a horizontal support roller 22 is fixed on the beam 25, and a vertical vertical plate 1 is connected to the beam 25 , the middle part of the vertical vertical plate 1 is fixed with a hinge shaft seat 2, the bottom of the vertical vertical plate 1 is hinged with the rod end of the swing cylinder 12, the cylinder seat of the swing cylinder 12 is hinged at one end of the support seat 4, and the other end of the support seat 4 It is hinged with the hinge shaft seat 2; the support seat 4 is fixed with a material hook cylinder 5, and the rod end of the material hook cylinder 5 is rotatably connected with a material hook roller 19.

[0021] In the present invention, the hinge s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com