Simple vertical stirrer

A vertical mixer, a simple technology, applied to mixers with rotary stirring devices, mixers, dissolving, etc., can solve the problems of low assembly requirements for the blade and the axis of the stirring shaft, food spoilage and rot, and affect food safety, etc., to achieve Easy to clean and maintain, prevent chemical reaction, high stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

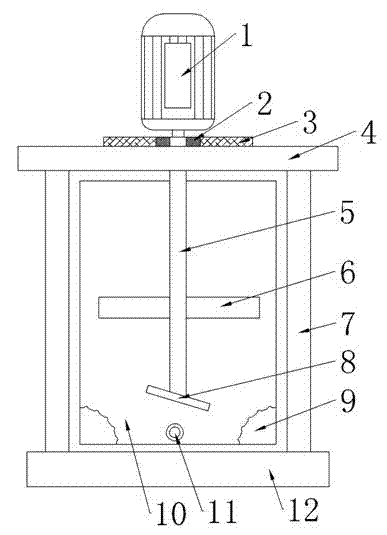

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0018] see figure 1 A preferred embodiment of a simple vertical mixer, the entire mixing bucket 10 is located in the bracket 7, and the bottom of the bracket 7 is connected to the bottom backing plate 12, and the top of the backing plate 12 passes through two vertical support rods on the side Connect the beam 4, and a ceramic backing plate 3 is set on the beam 4, and a stirring motor 3 is set on the ceramic backing plate 3, and a rubber ring 2 is set in the installation gap between the stirring motor 3 and the ceramic backing plate 3 Carry out limit and running buffer.

[0019] And the bottom of the stirring motor 3 is installed with a stirring shaft 5 extending into the mixing tank 10, two groups of stirring blades are arranged on the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com