A LED light source that excites fluorescent powder on multiple surfaces

An LED light source and phosphor technology, applied in the field of light sources, can solve the problems of limited LED light source brightness improvement, inability to produce white light output, low phosphor excitation energy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

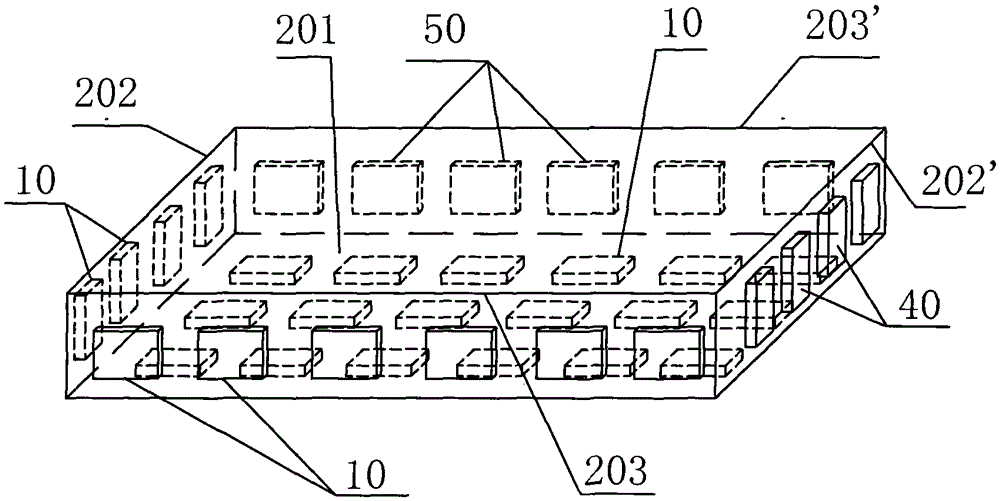

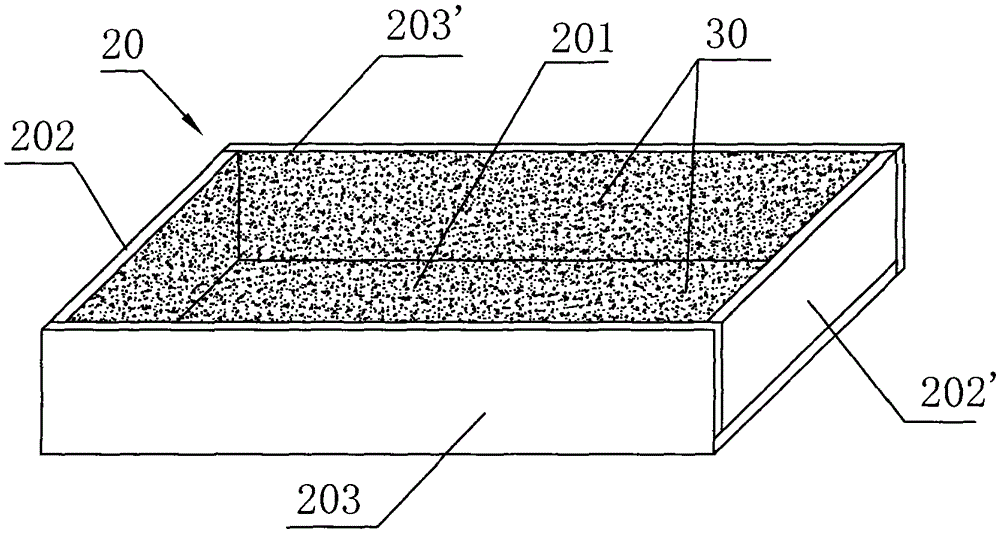

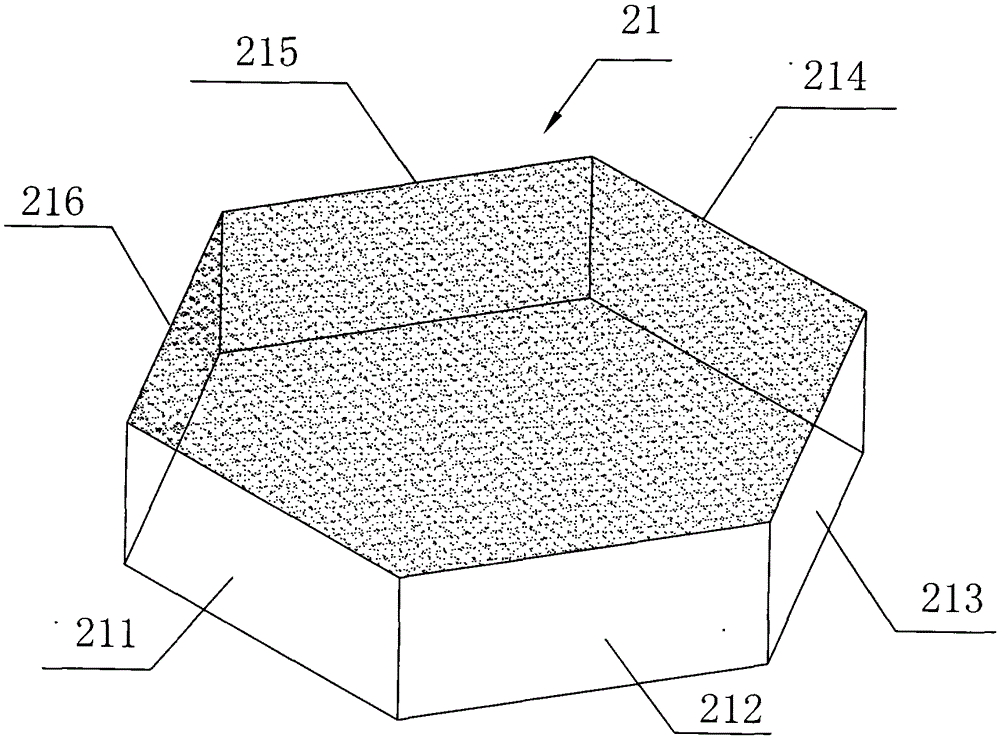

[0011] refer to figure 1 , figure 2 ,in, figure 1 Shown is a schematic structural diagram of an LED light source for multi-faceted excitation of phosphors according to the first embodiment of the present invention, figure 2 for figure 1 Schematic diagram of the structure of the multi-faceted carrier and the phosphor layer. The LED light source for multi-faceted excitation of phosphors includes a first LED chip group 10 and a multi-faceted carrier 20 . Wherein, the first LED chipset 10 emits the first pumping light. The multi-sided carrier 20 includes a bottom surface 201 , at least four even-numbered sides perpendicular to the bottom surface 201 , and an opening or a top surface opposite to the bottom surface 201 .

[0012] The first LED chip group 10 is disposed on the bottom surface 201 of the multi-sided carrier 20 and at least one side of the multi-sided carrier 20 . In the embodiment of the present invention, the bottom surface 201 and the outer surface of the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com