Sampler with rolling-over function

A sampler and functional technology, applied in the field of samplers with flip function, can solve the problems of high labor intensity, low accuracy performance, limited sampling range, etc., and achieve the effects of reasonable structure design, uniform sampling, and high accuracy performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

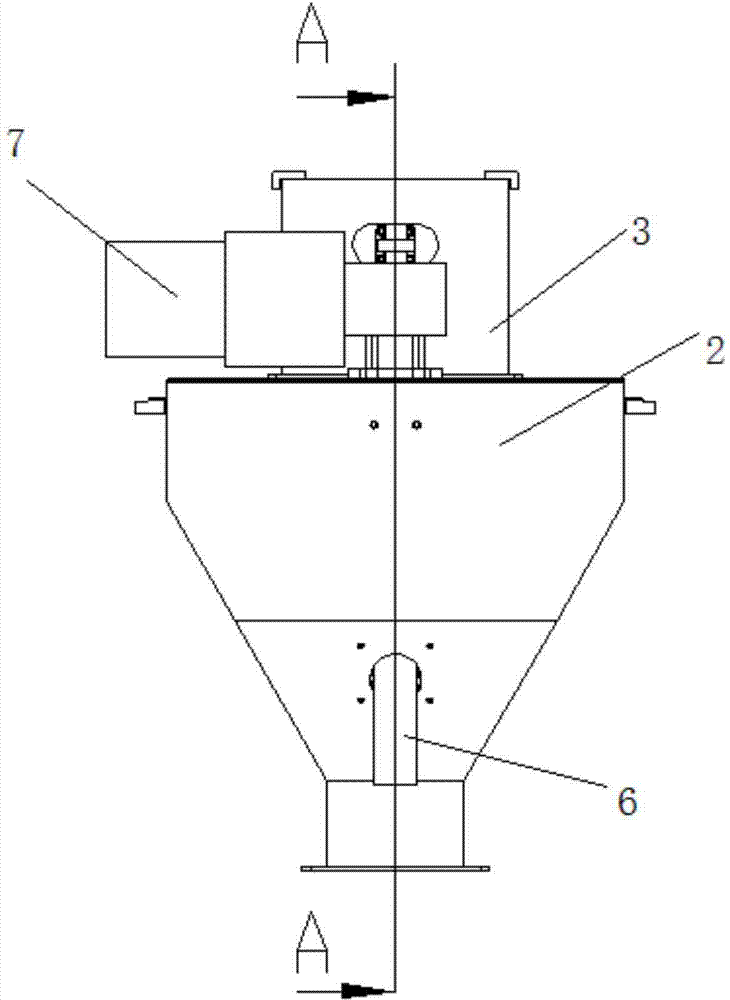

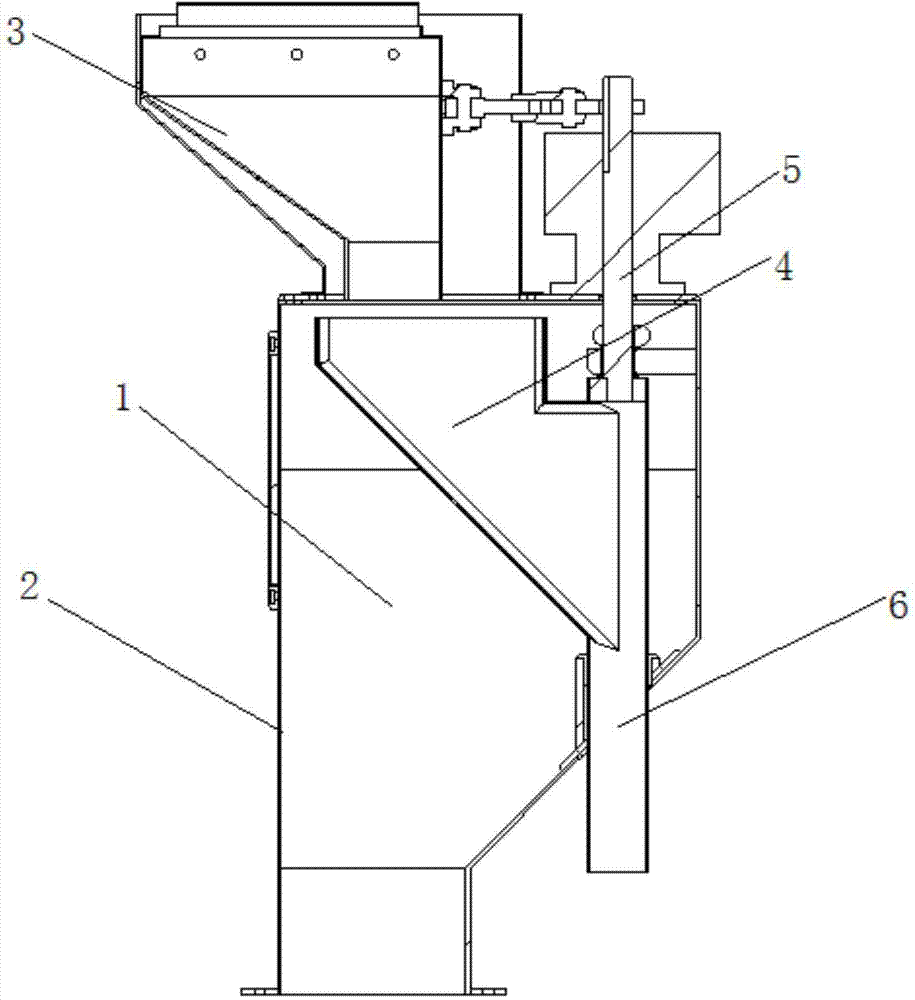

[0011] Referring to the accompanying drawings, a sampler with an overturning function includes a hood 2 with a feeding pipe 1, a feed hopper 3 is arranged on the hood, and a rotatable 180 is installed in the hood below the feed hopper 3. Sampling passage 4 of high degree, sampling passage 4 is installed on the side of machine cover 2 by rotating shaft 5, and the lower end of rotating shaft 5 is provided with the sampling pipe 6 that communicates with sampling passage 4, and rotating shaft 5 is driven by the motor 7 above it. The sampling pipeline 4 is a combined pipe structure in which the upper end is a straight pipe body and the lower end is an inclined pipe body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com